1830

Mercedes 300SL "Gullwing" with his own hands.

In search of material, I stumbled on a blog, in which he described how he created the machine. This was not just any car, but the car legend with an interesting history - Mercedes 300SL «Gullwing».

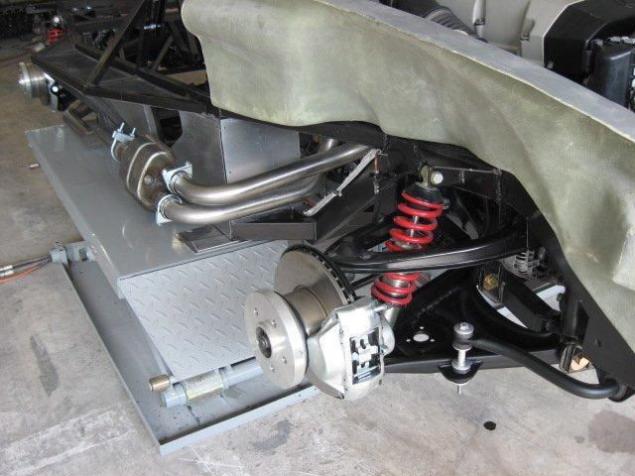

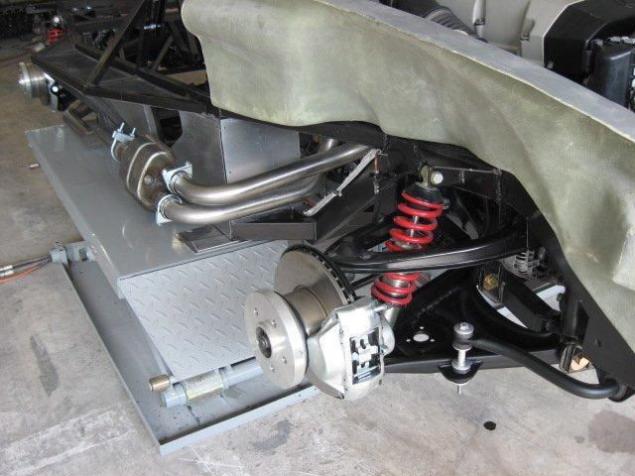

In the process of creating a Mercedes 300SL «Gullwing» was used suspension from the Mercedes W202 and W107. Keeping in mind that the best - the enemy good set adjustable dampers. Particular attention should be paid to the rear differential, typically with it having the biggest problems, which is why so customizers like not cutting bridges. On the Mercedes unit with actuators assembled on a stretcher, a lot easier to work with him.

The exhaust system is made of stainless steel complies with Euro 3 and the fuel tank - a work of art: that the fuel is not lapped, there are barriers and the overflow pipe. On one of the photos - the lock steering lock

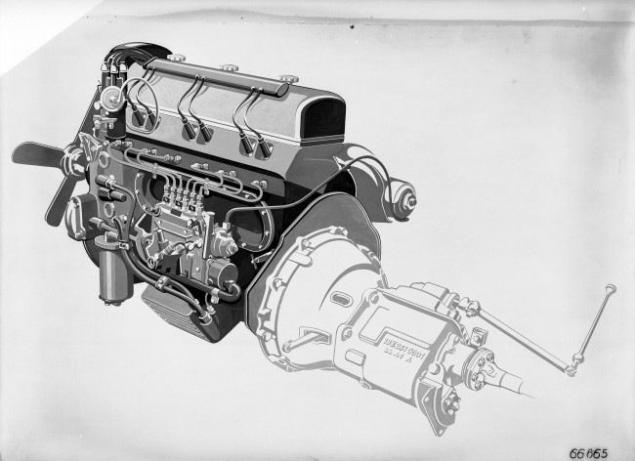

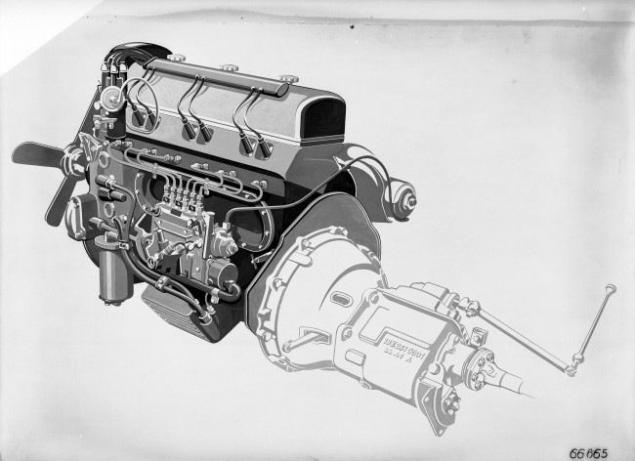

The project «Gullwing» was decided to use the next generation of engines M104 Volume 3, 2 liters and 220 hp paired with a 5-speed automatic sending. Motor selection was not accidental - it is more powerful, lighter and quieter. Transmission primitive, with torque converter, many of these units familiar from the Mercedes W124, W140, W129, W210. Was also set power, all new units, so that should be no problem.

Making the body.

Back in 1955, "Daimler Benz" produced 20 vehicles with an aluminum body and 1 composite. We decided to try the composite.

After construction of the body and chassis assembly begins with the crossing of the body frame. The process is so laborious and tedious that no photos and the words do not give. Assembly and disassembly, fit - everything it takes more than one day. Many of the details are being finalized on the spot, and the body is attached to the frame through special demfiry bolts in 30 locations.

Install and customize any body parts - doors, hood, trunk lid. A lot of trouble with the glasses - they are mounted on rubber seals, as well as all original seals and are designed for steel, it is necessary to adhere strictly to the thickness of the frames of openings. Every detail is removed, adjusted manually and then set into place.

Many of the details on the most popular rare model is still produced in some small-scale shops than actively use all restorers. What's there to be honest: plants themselves forge their curiosities, particularly successful in this, "Mercedes" and "Mercedes».

Many museums are frank copies. So in recent years it has bred a lot of "Horch". This is particularly interesting, given that the whole factory documentation was lost during the war. Dozens of workshops on the equipment of that time stamp forgery, giving them a thoroughly reconditioned products. The devil is in the details.

So we just bought and collected all the items that could decorate any curiosity over 500 thousand. Euro. I assure you, every Gadget and bolt, (I'm not talking about the gum) have the correct markings in 1955. Original everything, even the seat rails.

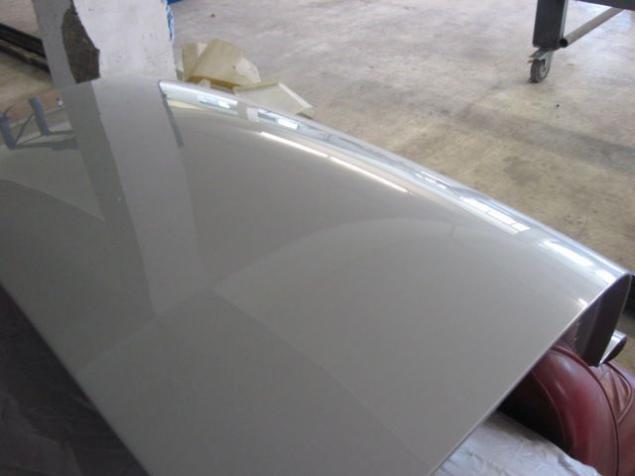

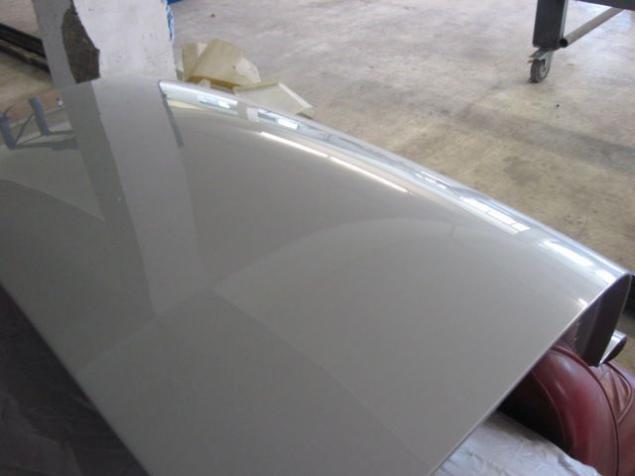

That's already primed the body and is the main point for the composite - in a special painting material because there need plasticizers, and all sorts of other complicated things. Secrets primer cherish and no one will ever tell them not to. But it looks nice.

Let us preparations for assembly units. As I said before - the devil is in the details, and them in the car for more than 2 million! The instrument panel, it looked for a long time.

Priborchik relay also find, of course, not all turns out right.

But with an enviable patience and perseverance you will be able to get a fully authentic instrument panel consisting of 80 (!) Parts.

The main thing is that it then also earned: priborchiki-all expensive. Cheap good does not happen.

The body is covered with 6 layers of lacquer, it is very beautiful and do not have to hang chrome film. Yes, shagreen - is certainly, well, that was a fine grain. Now so do not paint, all diluted with water, the environment they have, cherish nature. By the way, the paint 744 (silver) the most difficult for painting, a painter will tell you any.

Married finally chassis with bodywork.

Installed doors. It would seem that it's not tricky, but I want to tell you a story. Mercedes 300SL «Gullwing» had many design flaws. One of them was in fact the door: they were steel, heavy hinges, and fastened to the roof of the body, and fixed spring enclosed between the hollow steel tubes with hinges at the end.

In the uppermost position the spring is compressed and stretched when lowering the door with a crash slammed the door. When opening it was necessary to overcome the resistance of spring that just tore the door with brackets (at 900 euros per share).

Experienced owners «Gullwing» know that the inept use of it will inevitably lead to deformation of the roof, besides themselves brackets simply break. The rod with a spring assembly eventually became furious deficit and the cost had risen to astronomical heights. Every owner of such rarity repair these units once a season. We decided to go the other way and put gas shock absorbers.

It would be easy, but there it was. We had to develop a whole unit, it took 4 months of hard work. Fortunately, I found a workshop embodied ideas and drawings to life. With the full authenticity of the external doors now open the rear fifth door the German SUV. Node to be so successful that it immediately became the object of desire of all the owners of rarities, I think that soon all "gulvingi" will have a very efektno and smoothly, without knocking the door. Now this process really was like a wave of the gull-wing - gracefully and smoothly.

This is only one, and the simplest example of the challenges that had to be addressed in the construction of the car.

By the way the door lock mechanism also underwent changes. Despite the value of the euro in 1500, he very often have seized and did not fix the door, but that's another story.

Interior details on my kid did 4 months. The skin just like a living.

I will add that she leather, which now offer manufacturers - this is bullshit chemical impregnated. No wonder all owners of Mercedes and BMW cars after year of operation ofigivaet - salons look like vintage redvanov not fresh, the skin is pulled, peeling off. As I said earlier - the devil is in the details.

I'm not talking about vinyl, widely used by the Japanese, and all the producers in general. Now Mercedes leather jacket and is not enough, one shit, so there are options - "designo", "individual", "exclusive". Leading manufacturers, at least for 10-15 thousand. Dollars offer you the real skin, and what you sew for 50 thousand. Rubles skin even not dare to call.

Wheels - one of the most important parts of the car. That's our handsome, there are two types of wheels. First staged in the civil version.

The second offered as an option. They came out of the sport - the real thing, with a central nut. Certainly nice to have chrome wheels, but the price in the 5 th. Euros for the wheel a few strains.

How then thrash hammer on the nut, knowing that it is gold? The original drive for classics is also not cheap - 3 thousand. Euro. So I think, is sick I want to 8 thousand. Euro save.

One major factor is the operation of the engine Exhaust system (combustion products). I do not want to remember the laws of thermodynamics here, except to say that the last 150 years, the exhaust pipe is a symbol of progress. Remember locomotive pipes, ships, blast furnaces. Remembering my love for detail, I want to assure you that this pipe was given the highest priority. It is a masterpiece of engineering.

There is a saying - it is better to see once, than hundred times to read about it. Everyone who reads and watches my blog know my favorite expression - the devil is in the details. It is these details, I'll show you today. It makes no sense for a long time to write, you'll understand.

Wiring harnesses and braided, well, this I think you just have not seen, two-tone horn, in short, just look, all this is called Technology.

The main problem facing the implementation of this project was to create a total authenticity of all the interior details. It would seem that could be easier than to copy the sample available, but as they say, it's not that simple, and much more complex than even restore.

So, we had to make it work all analog devices, and operate correctly with the electronic components of modern machines; stick in a tight bunch avtomobilchik additional equipment such as air conditioning, power, power brakes. All of this should work full-time and toggle switches. Flaps stove used to have mechanical drive on the Volga Gaz 21, because it was necessary to alter fundamentally and stove. But the biggest problem was the production of gear selector.

All the difficulty was that the car was originally built for the sport, was small and very low, even the engine had to be placed at an angle of 30 degrees to the silhouette of the machine is not broken. The box was placed in a tunnel and had a direct pivot drive.

Between the box and the box itself was not more than 2 cm. Of free space. I have already said that the machine itself was cramped and very noisy, it was necessary to solve this problem. Since the standard was taken steam-engine box, the task has become more difficult because the automatic transmission is much greater in size and has a completely different management principle.

After much anguish was designed hinge and linkage, will fully simulate the assembly, as is easily seen by looking at the original.

Well, the most interesting thing: if you carefully read the pictures, you will see that seats are much lower than the original, this is also a trick. The fact that the car was so close that the man with the growth of 180 cm. Rested his head on the roof and was forced to sit hunched over at the helm, I like to go on straight arms, because it was necessary to change the angle of the steering column to provide comfort and violate the general view. How this was achieved - it is a novel, beginning with the production of unique slide down to reworking the floor and seats.

I'm not the first who decided to recreate the legendary car. Back in the late '70s in the US were made similar attempts, the furthest advanced Ostermaer Tony, a former mechanical engineer from Gardena. He managed to build over 10 years around 15 vehicles with units from the Mercedes of those years. Today, these machines themselves are rarities.

I saw them, of course it is far from such quality products as we would like, but it is the best that has been done. In 90 years there have been attempts of the American company "Speedster" using a matrix implant it on Tony nodes "Chevrolet Corvette C03." 2 was produced in all vehicles. One of them is now in Ukraine, and the other in Moscow. The machines were sold to 150 thousand. $.

Actually it all. It is true there have been attempts to put on a shell on SL and a lot of loud statements, but it is zilch, people fled ahead of the engine as our e-mobil: still nothing, but already 40 thousand. Applications filed.

By the way, working with the composite is very complicated. Only his quality painting is worth about 10 thousand. Euro. And most importantly: to forge and copy is the two big differences.

It is said that in the car everything should be fine, and the engine and the trunk. The first car decided to use gas shock absorbers for opening and locking the tailgate.

We are a little altered the filler neck, reasonably believing that if it is sealed to the trunk lid. it will reduce the risk of spreading the smell of gasoline inside the passenger compartment in the event of the strait.

I did not like the idea. On this machine made closer to the original, changing only the shape of the filler neck (steel funnel around the lid should prevent fuel spillage on the Carpet).

Of course, without the collective farm has not done: built around a leather condom filler. It seems to look pretty, and refused to shock, putting native mechanism (stick) locking tailgate. One could of course zamorochitsya with springs as on modern machines, but I think it will kill the spirit of the car. It looks nice in the trunk open.

And the rear, it looks very cool. Given that today all use tubeless tires, decided to free up space by placing in the trunk dokatku instead of the standard wheels. Now though there is much to throw a string bag.

Actually, the case moves inexorably to its logical conclusion. Sure glad that everything ends so fast, there pomazyukat movilchikom and prilyapat wheels.

The Wheel of Time, not to ugvazdat original.

That's basically all!

Source: kak-eto-sdelano.livejournal.com

In the process of creating a Mercedes 300SL «Gullwing» was used suspension from the Mercedes W202 and W107. Keeping in mind that the best - the enemy good set adjustable dampers. Particular attention should be paid to the rear differential, typically with it having the biggest problems, which is why so customizers like not cutting bridges. On the Mercedes unit with actuators assembled on a stretcher, a lot easier to work with him.

The exhaust system is made of stainless steel complies with Euro 3 and the fuel tank - a work of art: that the fuel is not lapped, there are barriers and the overflow pipe. On one of the photos - the lock steering lock

The project «Gullwing» was decided to use the next generation of engines M104 Volume 3, 2 liters and 220 hp paired with a 5-speed automatic sending. Motor selection was not accidental - it is more powerful, lighter and quieter. Transmission primitive, with torque converter, many of these units familiar from the Mercedes W124, W140, W129, W210. Was also set power, all new units, so that should be no problem.

Making the body.

Back in 1955, "Daimler Benz" produced 20 vehicles with an aluminum body and 1 composite. We decided to try the composite.

After construction of the body and chassis assembly begins with the crossing of the body frame. The process is so laborious and tedious that no photos and the words do not give. Assembly and disassembly, fit - everything it takes more than one day. Many of the details are being finalized on the spot, and the body is attached to the frame through special demfiry bolts in 30 locations.

Install and customize any body parts - doors, hood, trunk lid. A lot of trouble with the glasses - they are mounted on rubber seals, as well as all original seals and are designed for steel, it is necessary to adhere strictly to the thickness of the frames of openings. Every detail is removed, adjusted manually and then set into place.

Many of the details on the most popular rare model is still produced in some small-scale shops than actively use all restorers. What's there to be honest: plants themselves forge their curiosities, particularly successful in this, "Mercedes" and "Mercedes».

Many museums are frank copies. So in recent years it has bred a lot of "Horch". This is particularly interesting, given that the whole factory documentation was lost during the war. Dozens of workshops on the equipment of that time stamp forgery, giving them a thoroughly reconditioned products. The devil is in the details.

So we just bought and collected all the items that could decorate any curiosity over 500 thousand. Euro. I assure you, every Gadget and bolt, (I'm not talking about the gum) have the correct markings in 1955. Original everything, even the seat rails.

That's already primed the body and is the main point for the composite - in a special painting material because there need plasticizers, and all sorts of other complicated things. Secrets primer cherish and no one will ever tell them not to. But it looks nice.

Let us preparations for assembly units. As I said before - the devil is in the details, and them in the car for more than 2 million! The instrument panel, it looked for a long time.

Priborchik relay also find, of course, not all turns out right.

But with an enviable patience and perseverance you will be able to get a fully authentic instrument panel consisting of 80 (!) Parts.

The main thing is that it then also earned: priborchiki-all expensive. Cheap good does not happen.

The body is covered with 6 layers of lacquer, it is very beautiful and do not have to hang chrome film. Yes, shagreen - is certainly, well, that was a fine grain. Now so do not paint, all diluted with water, the environment they have, cherish nature. By the way, the paint 744 (silver) the most difficult for painting, a painter will tell you any.

Married finally chassis with bodywork.

Installed doors. It would seem that it's not tricky, but I want to tell you a story. Mercedes 300SL «Gullwing» had many design flaws. One of them was in fact the door: they were steel, heavy hinges, and fastened to the roof of the body, and fixed spring enclosed between the hollow steel tubes with hinges at the end.

In the uppermost position the spring is compressed and stretched when lowering the door with a crash slammed the door. When opening it was necessary to overcome the resistance of spring that just tore the door with brackets (at 900 euros per share).

Experienced owners «Gullwing» know that the inept use of it will inevitably lead to deformation of the roof, besides themselves brackets simply break. The rod with a spring assembly eventually became furious deficit and the cost had risen to astronomical heights. Every owner of such rarity repair these units once a season. We decided to go the other way and put gas shock absorbers.

It would be easy, but there it was. We had to develop a whole unit, it took 4 months of hard work. Fortunately, I found a workshop embodied ideas and drawings to life. With the full authenticity of the external doors now open the rear fifth door the German SUV. Node to be so successful that it immediately became the object of desire of all the owners of rarities, I think that soon all "gulvingi" will have a very efektno and smoothly, without knocking the door. Now this process really was like a wave of the gull-wing - gracefully and smoothly.

This is only one, and the simplest example of the challenges that had to be addressed in the construction of the car.

By the way the door lock mechanism also underwent changes. Despite the value of the euro in 1500, he very often have seized and did not fix the door, but that's another story.

Interior details on my kid did 4 months. The skin just like a living.

I will add that she leather, which now offer manufacturers - this is bullshit chemical impregnated. No wonder all owners of Mercedes and BMW cars after year of operation ofigivaet - salons look like vintage redvanov not fresh, the skin is pulled, peeling off. As I said earlier - the devil is in the details.

I'm not talking about vinyl, widely used by the Japanese, and all the producers in general. Now Mercedes leather jacket and is not enough, one shit, so there are options - "designo", "individual", "exclusive". Leading manufacturers, at least for 10-15 thousand. Dollars offer you the real skin, and what you sew for 50 thousand. Rubles skin even not dare to call.

Wheels - one of the most important parts of the car. That's our handsome, there are two types of wheels. First staged in the civil version.

The second offered as an option. They came out of the sport - the real thing, with a central nut. Certainly nice to have chrome wheels, but the price in the 5 th. Euros for the wheel a few strains.

How then thrash hammer on the nut, knowing that it is gold? The original drive for classics is also not cheap - 3 thousand. Euro. So I think, is sick I want to 8 thousand. Euro save.

One major factor is the operation of the engine Exhaust system (combustion products). I do not want to remember the laws of thermodynamics here, except to say that the last 150 years, the exhaust pipe is a symbol of progress. Remember locomotive pipes, ships, blast furnaces. Remembering my love for detail, I want to assure you that this pipe was given the highest priority. It is a masterpiece of engineering.

There is a saying - it is better to see once, than hundred times to read about it. Everyone who reads and watches my blog know my favorite expression - the devil is in the details. It is these details, I'll show you today. It makes no sense for a long time to write, you'll understand.

Wiring harnesses and braided, well, this I think you just have not seen, two-tone horn, in short, just look, all this is called Technology.

The main problem facing the implementation of this project was to create a total authenticity of all the interior details. It would seem that could be easier than to copy the sample available, but as they say, it's not that simple, and much more complex than even restore.

So, we had to make it work all analog devices, and operate correctly with the electronic components of modern machines; stick in a tight bunch avtomobilchik additional equipment such as air conditioning, power, power brakes. All of this should work full-time and toggle switches. Flaps stove used to have mechanical drive on the Volga Gaz 21, because it was necessary to alter fundamentally and stove. But the biggest problem was the production of gear selector.

All the difficulty was that the car was originally built for the sport, was small and very low, even the engine had to be placed at an angle of 30 degrees to the silhouette of the machine is not broken. The box was placed in a tunnel and had a direct pivot drive.

Between the box and the box itself was not more than 2 cm. Of free space. I have already said that the machine itself was cramped and very noisy, it was necessary to solve this problem. Since the standard was taken steam-engine box, the task has become more difficult because the automatic transmission is much greater in size and has a completely different management principle.

After much anguish was designed hinge and linkage, will fully simulate the assembly, as is easily seen by looking at the original.

Well, the most interesting thing: if you carefully read the pictures, you will see that seats are much lower than the original, this is also a trick. The fact that the car was so close that the man with the growth of 180 cm. Rested his head on the roof and was forced to sit hunched over at the helm, I like to go on straight arms, because it was necessary to change the angle of the steering column to provide comfort and violate the general view. How this was achieved - it is a novel, beginning with the production of unique slide down to reworking the floor and seats.

I'm not the first who decided to recreate the legendary car. Back in the late '70s in the US were made similar attempts, the furthest advanced Ostermaer Tony, a former mechanical engineer from Gardena. He managed to build over 10 years around 15 vehicles with units from the Mercedes of those years. Today, these machines themselves are rarities.

I saw them, of course it is far from such quality products as we would like, but it is the best that has been done. In 90 years there have been attempts of the American company "Speedster" using a matrix implant it on Tony nodes "Chevrolet Corvette C03." 2 was produced in all vehicles. One of them is now in Ukraine, and the other in Moscow. The machines were sold to 150 thousand. $.

Actually it all. It is true there have been attempts to put on a shell on SL and a lot of loud statements, but it is zilch, people fled ahead of the engine as our e-mobil: still nothing, but already 40 thousand. Applications filed.

By the way, working with the composite is very complicated. Only his quality painting is worth about 10 thousand. Euro. And most importantly: to forge and copy is the two big differences.

It is said that in the car everything should be fine, and the engine and the trunk. The first car decided to use gas shock absorbers for opening and locking the tailgate.

We are a little altered the filler neck, reasonably believing that if it is sealed to the trunk lid. it will reduce the risk of spreading the smell of gasoline inside the passenger compartment in the event of the strait.

I did not like the idea. On this machine made closer to the original, changing only the shape of the filler neck (steel funnel around the lid should prevent fuel spillage on the Carpet).

Of course, without the collective farm has not done: built around a leather condom filler. It seems to look pretty, and refused to shock, putting native mechanism (stick) locking tailgate. One could of course zamorochitsya with springs as on modern machines, but I think it will kill the spirit of the car. It looks nice in the trunk open.

And the rear, it looks very cool. Given that today all use tubeless tires, decided to free up space by placing in the trunk dokatku instead of the standard wheels. Now though there is much to throw a string bag.

Actually, the case moves inexorably to its logical conclusion. Sure glad that everything ends so fast, there pomazyukat movilchikom and prilyapat wheels.

The Wheel of Time, not to ugvazdat original.

That's basically all!

Source: kak-eto-sdelano.livejournal.com