1697

Samsung plant in Kaluga. production of television

In Russia, the company Samsung is known primarily as a manufacturer of consumer electronics. Despite the fact that over 70% of Group sales accounted for the electronics industry, Samsung was noted in almost all sectors of business. Coeur ride on machine Samsung, Samsung has banks and insurance companies, there is an amusement park Samsung, hotels, advertising and construction companies.

01. But let us return to the TV. If you saw in the store TV Samsung made not in Russia, you know, you slip the old. All Samsung TVs are now doing in Russia. Not just collected, namely do. Let's start with the body. 02. To start from Korea bags come with the components for the production of plastic panels.

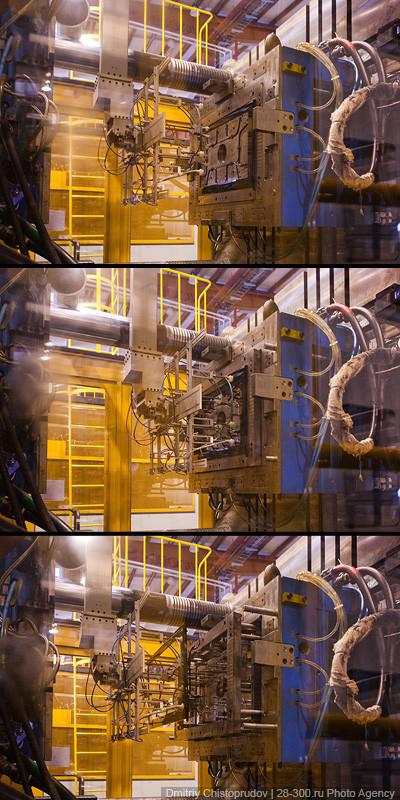

03. This is where all the whole thing is mixed, melted down the tubes and hot plastic under pressure is supplied to the plant for stamping TVs.

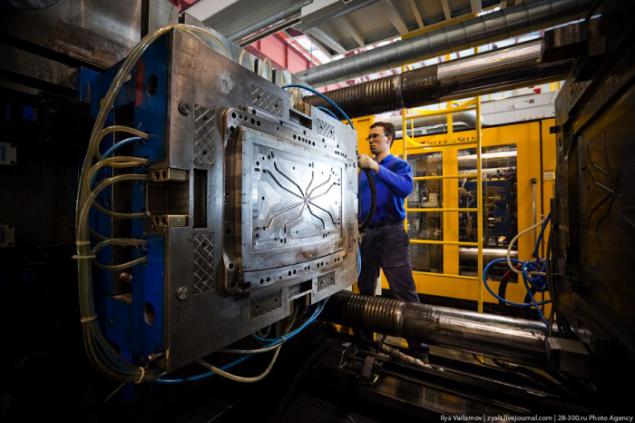

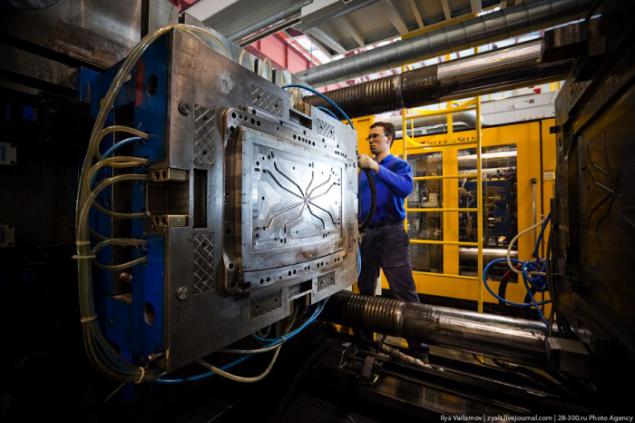

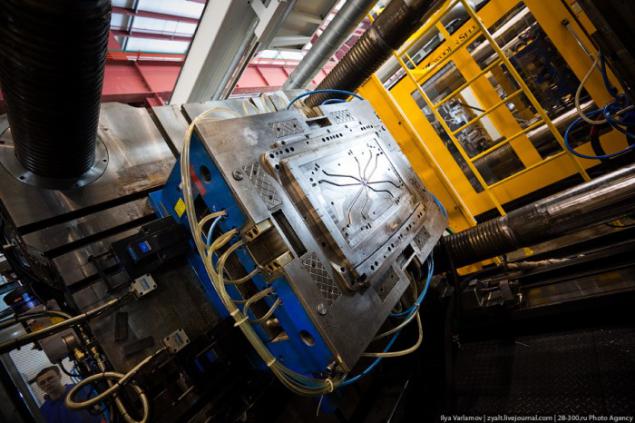

04. This mold for the production of the set. Here they are waiting in the wings, if necessary, of the install on the machine and will cast parts.

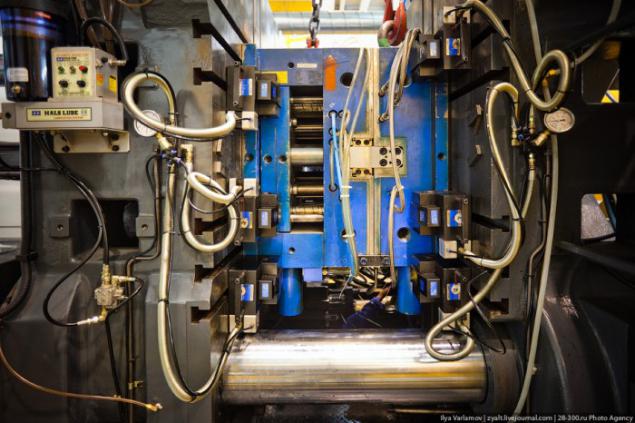

05. To install the molds used crane girders. The weight of one presformy can reach several tons.

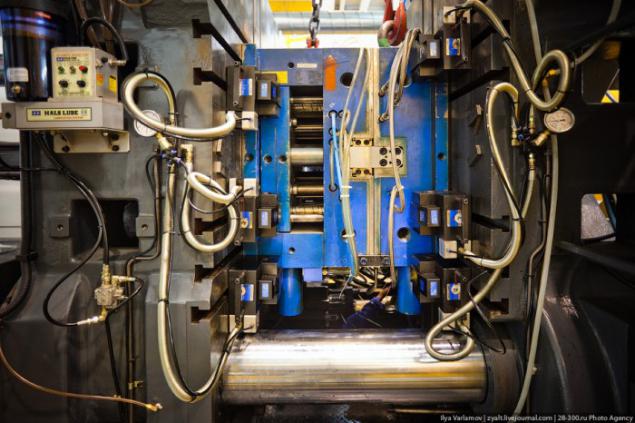

06. But the machines are installed in the mold. This pressure comes hot plastic under pressure it is injected into the mold and get the item

07. Normally, the body consists of the TV back cover and front frame.

08. In the production of one piece takes about 2 minutes, just the factory, I counted 15 machines for casting parts. All of them are similar and work with interchangeable molds.

10. All automated production, working only watch equipment.

11. Sometimes you have something to tighten up)

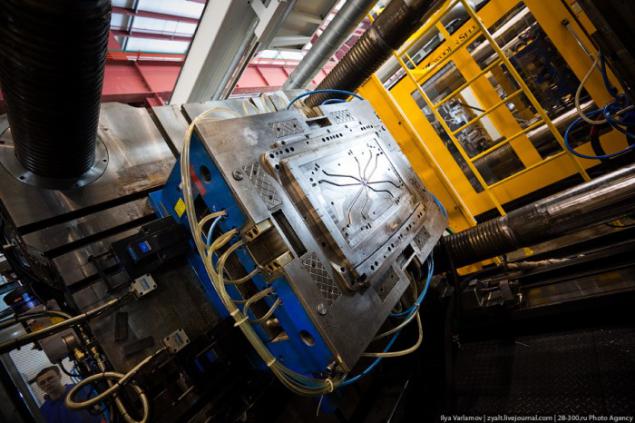

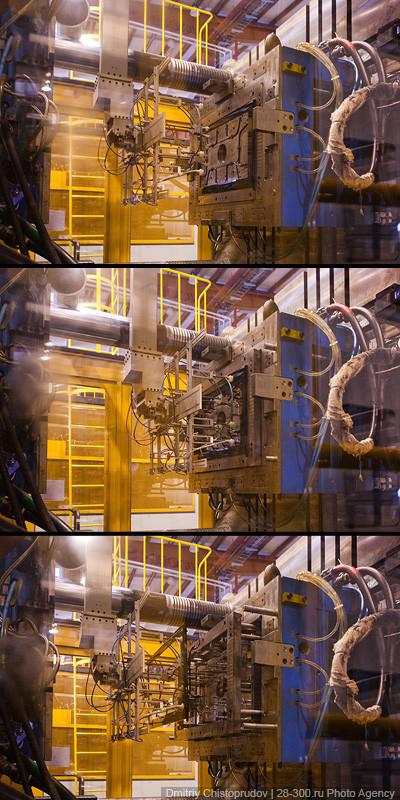

12. This is disclosed mold.

13.

14. Further, it is closed and under pressure is plastic.

15. PSHSHSHSCHSCHSCHSCHSCHSCH ...

16. And then the item is ready.

17. The robot puts it on tape and it goes to the next shop.

18. This excess plastic from the channel on which it was submitted. They are sent to recycling where izmelchat in small granules and will be used for the internal parts of TVs.

19. Suddenly worker opened some door and pulled out a large, hot piece of plastic.

20. This tseh in which plastic panel TV or monitor equipped with necessary fittings, stamped logos, etc.

21. She takes with ribbon panel, and puts it on a machine that makes the logos.

22. Here is a pink pad puts on a faceless plastic Samsung logo. Similarly put down all other necessary markings and logos.

23. Here the panel are checked for defects. This can be anything you like crack, Nedolya, scratch, gas bubbles, traces of flux, stains, etc. If a defect is rejected panel.

24. To avoid scratching the faceplate, it immediately paste protective film.

25. Where did the Russian factory without a hammer? )

26. Further panels are supplied with the necessary details.

27.

28. The line of high quality, to say nothing)

29. And the final panel is sent to the warehouse.

30. All of the components are stored in a warehouse in special containers.

31. Each container has wheels as necessary robots carry about these people containers on the conveyors.

32. This robot carries matrix production. Road robots learn by colored stripes on the floor. During the movement of the robot plays stupid music.

33. This workshop for the production of chips. Here, everything happens automatically.

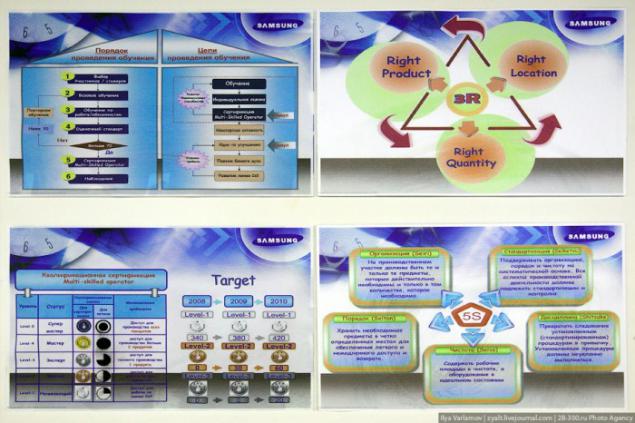

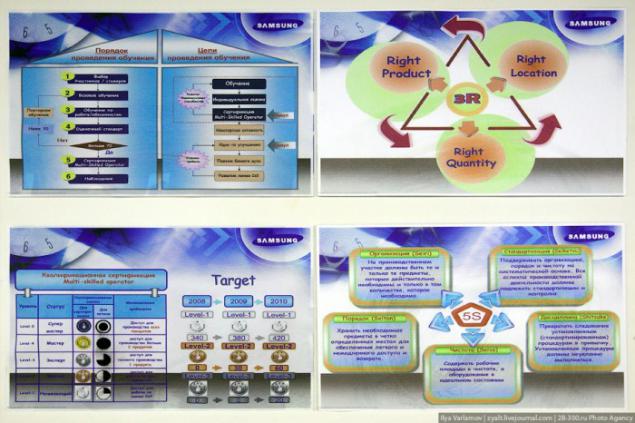

Table 34. Quality Control.

35. Now a little about the traditions of the factory. Most of all I was surprised by the slogans written on the shop floor in the best traditions of the Soviet era. Nothing but laughter from the workers they do not cause, but the Koreans probably think that they will help Russian natives to work. I will quote some of them:

- Quality products SERK starts with us !!! (Serck - is Samsung Electronics Rus Kaluga)

- Our will can not be broken: Lily, and will pour pouring !!!

- Work with dedication, no one will zhto better than you.

- Bummer production chase, they spoil our cars!

- Increase productivity up to 700,000, reducing waste!

- YES-quality at Cell, NO Brac!

- Working time - time to work!

36. As you can see, everything is done to ensure that workers do not get bored. By the way, almost all the factory workers are young people. Salary on the conveyor 25,000, plus benefits package, career prospects.

37. In general, the plant is very cool, perfect cleanliness, pleasant young people, everything is automated, inside can not believe it's Kaluga region, rather than Korea. So that no one forgets the factory decided to make zagonchik for working in the style of a provincial cheap eatery. The clearest example of Russian bad taste.

38. A similar situation is happening in the stands.

zyalt

01. But let us return to the TV. If you saw in the store TV Samsung made not in Russia, you know, you slip the old. All Samsung TVs are now doing in Russia. Not just collected, namely do. Let's start with the body. 02. To start from Korea bags come with the components for the production of plastic panels.

03. This is where all the whole thing is mixed, melted down the tubes and hot plastic under pressure is supplied to the plant for stamping TVs.

04. This mold for the production of the set. Here they are waiting in the wings, if necessary, of the install on the machine and will cast parts.

05. To install the molds used crane girders. The weight of one presformy can reach several tons.

06. But the machines are installed in the mold. This pressure comes hot plastic under pressure it is injected into the mold and get the item

07. Normally, the body consists of the TV back cover and front frame.

08. In the production of one piece takes about 2 minutes, just the factory, I counted 15 machines for casting parts. All of them are similar and work with interchangeable molds.

10. All automated production, working only watch equipment.

11. Sometimes you have something to tighten up)

12. This is disclosed mold.

13.

14. Further, it is closed and under pressure is plastic.

15. PSHSHSHSCHSCHSCHSCHSCHSCH ...

16. And then the item is ready.

17. The robot puts it on tape and it goes to the next shop.

18. This excess plastic from the channel on which it was submitted. They are sent to recycling where izmelchat in small granules and will be used for the internal parts of TVs.

19. Suddenly worker opened some door and pulled out a large, hot piece of plastic.

20. This tseh in which plastic panel TV or monitor equipped with necessary fittings, stamped logos, etc.

21. She takes with ribbon panel, and puts it on a machine that makes the logos.

22. Here is a pink pad puts on a faceless plastic Samsung logo. Similarly put down all other necessary markings and logos.

23. Here the panel are checked for defects. This can be anything you like crack, Nedolya, scratch, gas bubbles, traces of flux, stains, etc. If a defect is rejected panel.

24. To avoid scratching the faceplate, it immediately paste protective film.

25. Where did the Russian factory without a hammer? )

26. Further panels are supplied with the necessary details.

27.

28. The line of high quality, to say nothing)

29. And the final panel is sent to the warehouse.

30. All of the components are stored in a warehouse in special containers.

31. Each container has wheels as necessary robots carry about these people containers on the conveyors.

32. This robot carries matrix production. Road robots learn by colored stripes on the floor. During the movement of the robot plays stupid music.

33. This workshop for the production of chips. Here, everything happens automatically.

Table 34. Quality Control.

35. Now a little about the traditions of the factory. Most of all I was surprised by the slogans written on the shop floor in the best traditions of the Soviet era. Nothing but laughter from the workers they do not cause, but the Koreans probably think that they will help Russian natives to work. I will quote some of them:

- Quality products SERK starts with us !!! (Serck - is Samsung Electronics Rus Kaluga)

- Our will can not be broken: Lily, and will pour pouring !!!

- Work with dedication, no one will zhto better than you.

- Bummer production chase, they spoil our cars!

- Increase productivity up to 700,000, reducing waste!

- YES-quality at Cell, NO Brac!

- Working time - time to work!

36. As you can see, everything is done to ensure that workers do not get bored. By the way, almost all the factory workers are young people. Salary on the conveyor 25,000, plus benefits package, career prospects.

37. In general, the plant is very cool, perfect cleanliness, pleasant young people, everything is automated, inside can not believe it's Kaluga region, rather than Korea. So that no one forgets the factory decided to make zagonchik for working in the style of a provincial cheap eatery. The clearest example of Russian bad taste.

38. A similar situation is happening in the stands.

zyalt