1284

How do samoletoy L-410 in the Czech Republic (41 photos)

L-410 UVP-E20 - a versatile twin-engine aircraft of Czech production for local airlines, accommodating 19 passengers. Designed for use on unprepared ground, grass, snow areas, as well as on the airfields with short runways (about 600-700 meters), that, in fact, makes it an aircraft in the category of "off-road". The first flight of the A-410 was made April 16, 1969. The main customer of the aircraft was the Soviet Union. In addition, L-410 is also available in Brazil, Bulgaria, Hungary, East Germany, Libya, Poland. Despite the fact that the factory is located in the Czech Republic, he considers himself a part of the Russian aircraft industry: foundation laid for this in its development and many years of operating history. As of 2012 in the world, operating more than 400 aircraft L-410.

production area of the company «Aircraft Industries» in Kunovice, Czech Republic.

Plant «Aircraft Industries», better known under the name Let Kunovice, located 300 km from Prague. The plant employs 920 people.

The company produces aircraft for the complete production cycle - has its own line of surface treatment materials, paint manufacturing, machine shop, assembly shop, design office and the airport.

Workshop production of fuselage A-410. The company is an expansion and modernization of production - light green accessories designed for the production of a new generation of aircraft L-410 NG (New Generation).

Proizvodtsvennaya capacity is 16-18 new aircraft per year.

About 80% of aircraft delivered in Russia. Over the past four years in Russia delivered 35 aircraft.

Production of parts on machining centers, CNC French company Creneau.

Cleaning parts prior to forming

Forming part in a press

Piercing press

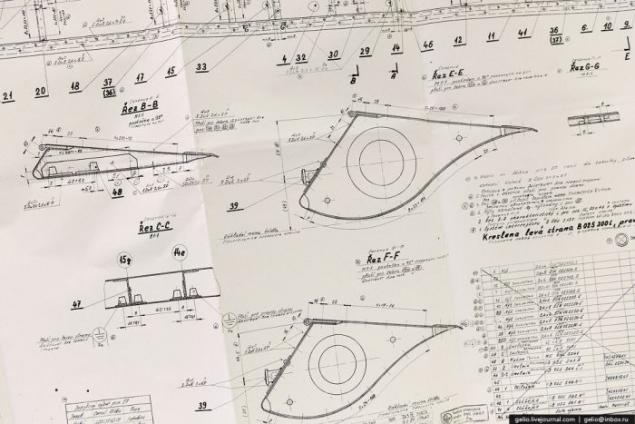

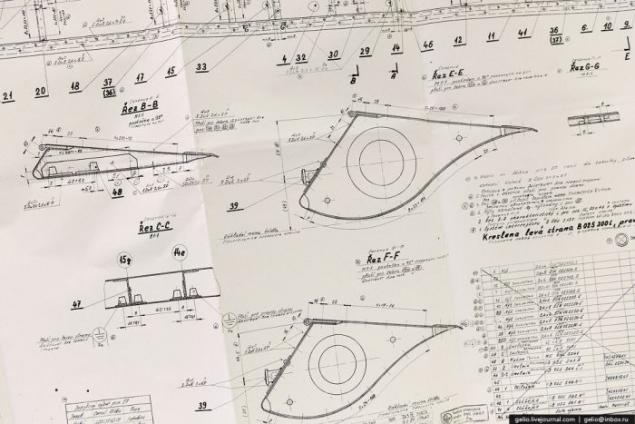

Design documentation - drawing spoiler

Production of the wing spar to 5-axis machining centers, CNC.

By manufacture the Russian duralumin manufactured by JSC "Kamensk-Uralsky Metallurgical Works." The total share of Russian components in the plane A-410 is about 15% - a legacy of the fact that the aircraft was developed by order of the USSR and with the participation of Soviet designers.

Production of the wing panel

Assembling the front of the wing

Quality riveting on the wing of the aircraft

On one plane L-410 is about 185,000 rivets of different types and sizes

Riveting work in the middle part of the fuselage

Installation of floor panels

Production of the rear fuselage

Production of details of the engine air intake

Production of parts for aircraft air intake SASA The CN-235 in the framework of industrial cooperation.

Also, the plant is carried out by cooperation with Boeing for the aircraft Boeing 787.

Mounting conveyor airplanes L-410 UVP-E20. Located in one of the new buildings of the plant, originally designed for the production of L-610.

In one half of the building there are two lines of production of new aircraft L-410, in the second half - shop service aircraft coming out of service.

At the same time in the assembly shop located about 10 aircraft. At the beginning of the line come from the workshop of painting the fuselage, wing, end tanks and empennage.

At the end of the line are planes that pass flight tests and being prepared for shipment to customers.

Over its history, the plant has produced more than 1,150 aircraft of the A-410.

More than 850 of them have been delivered to operators in the USSR.

The process of finishing the luggage compartment in the nose of the aircraft after the installation of electrical equipment

Assembling the emergency exit doors

The nose of the aircraft with serial number 2915. Visible weather radar antenna.

Opening the door nose luggage.

Installation of avionics in the cockpit. As part of the avionics equipment traditionally present Russian producers

Installation of electrical equipment in the cabin

Installing the wiring harness

Installation of electrical wires on the wing of the aircraft in the engine nacelle

Pyatilopostnye propellers AV-725 (manufactured by Avia Propeller), together with the engine GE H80-200 up a new power plant of the aircraft L-410 UVP-E20. It is set in January 2013 for all new aircraft and is certified by EASA and the Russian Interstate Aviation Committee.

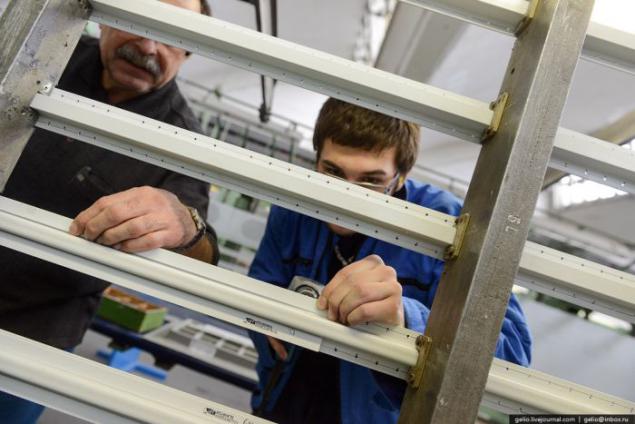

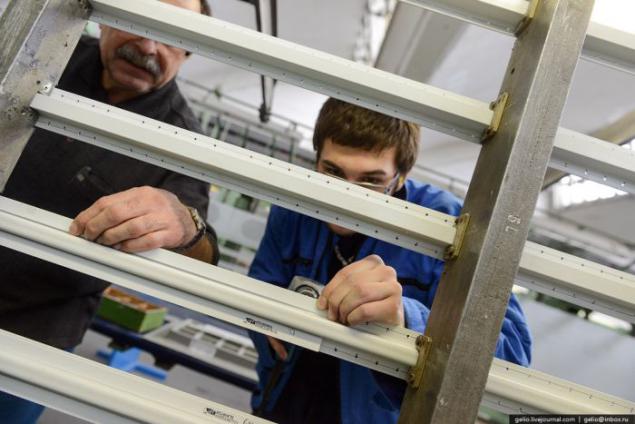

Young people in the production is not uncommon, including due to the presence of its own vocational schools are not inside the plant.

The average age of employees - '44.

Work on the engine GE H-80 that are held by the representative of the company GE Aviation Czech, Prague (former factory Walter).

Step final assembly takes about 5 months - this is the most expensive part of the production, because within it are set on a plane engines, chassis and all avionics, where each individual unit can cost 100-250 thousand. Euro.

The total duration of the production cycle of the aircraft from the production of the first components of the fuselage before the end of the flight test takes a little less than a year.

The cockpit of the aircraft L-410 UVP-E20.

The aircraft is fully equipped for instrument flight, it has a sophisticated system Proximity Warning land (GPWS) and collisions in the air (TCAS II). A 410 is designed in the metric system (not inches), which is an exception in the western aircraft.

This type of aircraft has been used for many years as an outlet for pilot training in Sasovo Flying School of Civil Aviation (Ryazan region.).

Preflight preparation. Stanislav Sklenarzh - chief test pilot plant.

Under the wing of the plane view of the river. Moravia Uherský Ostroh

Plane L-410 UVP-E20 for French Guiana.

Aircrafts for exotic countries often have vivid coloring memorable.

Care with curves

Service ceiling - 8000 m

Sunset vletno landing strip.

L-410 aircraft can land on the strip of paved, and on grass, gravel and snow. OHR in the name of the plane Russian acronym meaning "short takeoff and landing," which also recalls the roots of the Russian aircraft.

A prototype of the aircraft A-610M in the old place set for review at the entrance to the city

production area of the company «Aircraft Industries» in Kunovice, Czech Republic.

Plant «Aircraft Industries», better known under the name Let Kunovice, located 300 km from Prague. The plant employs 920 people.

The company produces aircraft for the complete production cycle - has its own line of surface treatment materials, paint manufacturing, machine shop, assembly shop, design office and the airport.

Workshop production of fuselage A-410. The company is an expansion and modernization of production - light green accessories designed for the production of a new generation of aircraft L-410 NG (New Generation).

Proizvodtsvennaya capacity is 16-18 new aircraft per year.

About 80% of aircraft delivered in Russia. Over the past four years in Russia delivered 35 aircraft.

Production of parts on machining centers, CNC French company Creneau.

Cleaning parts prior to forming

Forming part in a press

Piercing press

Design documentation - drawing spoiler

Production of the wing spar to 5-axis machining centers, CNC.

By manufacture the Russian duralumin manufactured by JSC "Kamensk-Uralsky Metallurgical Works." The total share of Russian components in the plane A-410 is about 15% - a legacy of the fact that the aircraft was developed by order of the USSR and with the participation of Soviet designers.

Production of the wing panel

Assembling the front of the wing

Quality riveting on the wing of the aircraft

On one plane L-410 is about 185,000 rivets of different types and sizes

Riveting work in the middle part of the fuselage

Installation of floor panels

Production of the rear fuselage

Production of details of the engine air intake

Production of parts for aircraft air intake SASA The CN-235 in the framework of industrial cooperation.

Also, the plant is carried out by cooperation with Boeing for the aircraft Boeing 787.

Mounting conveyor airplanes L-410 UVP-E20. Located in one of the new buildings of the plant, originally designed for the production of L-610.

In one half of the building there are two lines of production of new aircraft L-410, in the second half - shop service aircraft coming out of service.

At the same time in the assembly shop located about 10 aircraft. At the beginning of the line come from the workshop of painting the fuselage, wing, end tanks and empennage.

At the end of the line are planes that pass flight tests and being prepared for shipment to customers.

Over its history, the plant has produced more than 1,150 aircraft of the A-410.

More than 850 of them have been delivered to operators in the USSR.

The process of finishing the luggage compartment in the nose of the aircraft after the installation of electrical equipment

Assembling the emergency exit doors

The nose of the aircraft with serial number 2915. Visible weather radar antenna.

Opening the door nose luggage.

Installation of avionics in the cockpit. As part of the avionics equipment traditionally present Russian producers

Installation of electrical equipment in the cabin

Installing the wiring harness

Installation of electrical wires on the wing of the aircraft in the engine nacelle

Pyatilopostnye propellers AV-725 (manufactured by Avia Propeller), together with the engine GE H80-200 up a new power plant of the aircraft L-410 UVP-E20. It is set in January 2013 for all new aircraft and is certified by EASA and the Russian Interstate Aviation Committee.

Young people in the production is not uncommon, including due to the presence of its own vocational schools are not inside the plant.

The average age of employees - '44.

Work on the engine GE H-80 that are held by the representative of the company GE Aviation Czech, Prague (former factory Walter).

Step final assembly takes about 5 months - this is the most expensive part of the production, because within it are set on a plane engines, chassis and all avionics, where each individual unit can cost 100-250 thousand. Euro.

The total duration of the production cycle of the aircraft from the production of the first components of the fuselage before the end of the flight test takes a little less than a year.

The cockpit of the aircraft L-410 UVP-E20.

The aircraft is fully equipped for instrument flight, it has a sophisticated system Proximity Warning land (GPWS) and collisions in the air (TCAS II). A 410 is designed in the metric system (not inches), which is an exception in the western aircraft.

This type of aircraft has been used for many years as an outlet for pilot training in Sasovo Flying School of Civil Aviation (Ryazan region.).

Preflight preparation. Stanislav Sklenarzh - chief test pilot plant.

Under the wing of the plane view of the river. Moravia Uherský Ostroh

Plane L-410 UVP-E20 for French Guiana.

Aircrafts for exotic countries often have vivid coloring memorable.

Care with curves

Service ceiling - 8000 m

Sunset vletno landing strip.

L-410 aircraft can land on the strip of paved, and on grass, gravel and snow. OHR in the name of the plane Russian acronym meaning "short takeoff and landing," which also recalls the roots of the Russian aircraft.

A prototype of the aircraft A-610M in the old place set for review at the entrance to the city