1154

Waste sorting (11 photos)

Most of the wastes that we throw in the trash can be given a second life.

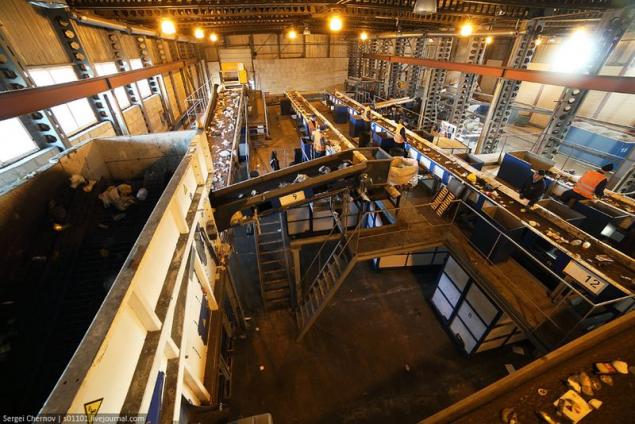

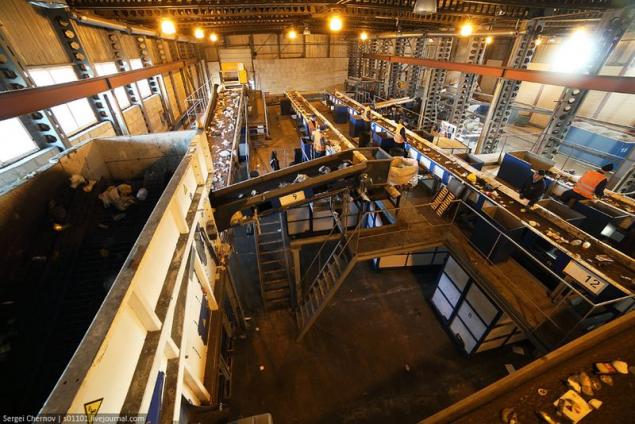

01. The collected waste from the company dumpsters get to the station and sent to the sorting process up the conveyor line.

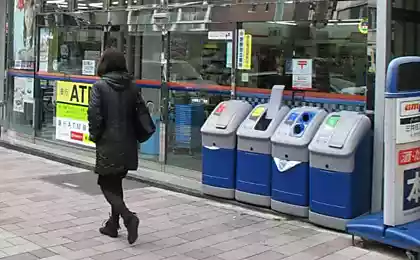

02. At the first stage by means of special magnets removed from the trash all the metal flow. In general, the metal on the company gets not much. As a general rule it in advance of the dumpsters removed homeless.

03. In the next step of the garbage removed all biodegradable waste. If you use a separate collection of waste, this process step is skipped.

04. Under the separate collection of wet storage is understood the biological materials in a container, and glass, metal, cardboard, plastic in another. Tariffs for garbage separation of garbage at Spetstrans lower than for the general. If your yard is equipped with appropriate containers may require the management company recalculate the receipt.

05. Once in the waste stream leaving only cardboard, plastic, polyethylene, they are bred on three different lines. That missed automation, finish people.

06. It is necessary to replace that of the enterprise in the territory of garbage is quite clean and does not stink. The rooms are well ventilated.

07. The sorted waste is sent to the compact.

08. At first glance it seems simple. In fact, each technology node is unique expensive equipment, which is required for maintenance of first-class professionals.

09. This technology allows a small yard of debris removed from the 70% of useful products, 25% of which is the energy fuel that is used in concrete plants.

10. Under the useful products is understood everything that could further poison for processing. This molded plastic, paper, metal.

11. At the moment, the sorting plant can let through about 100 thousand tons of garbage a year. That's about 10% of the total volume of transported Autopark №1. Across the St. Petersburg this proportion is even lower. The Flax. field there is nothing like it, not to mention the processing. Garbage in the best case just buried in landfills. Despite the high cost of equipment for a fairly short period of time, this mini-factory came to self-sufficiency. If such an approach for waste disposal, which in Europe has long been the standard we are used everywhere around the world will be cleaner.

Source: s01101.livejournal.com

01. The collected waste from the company dumpsters get to the station and sent to the sorting process up the conveyor line.

02. At the first stage by means of special magnets removed from the trash all the metal flow. In general, the metal on the company gets not much. As a general rule it in advance of the dumpsters removed homeless.

03. In the next step of the garbage removed all biodegradable waste. If you use a separate collection of waste, this process step is skipped.

04. Under the separate collection of wet storage is understood the biological materials in a container, and glass, metal, cardboard, plastic in another. Tariffs for garbage separation of garbage at Spetstrans lower than for the general. If your yard is equipped with appropriate containers may require the management company recalculate the receipt.

05. Once in the waste stream leaving only cardboard, plastic, polyethylene, they are bred on three different lines. That missed automation, finish people.

06. It is necessary to replace that of the enterprise in the territory of garbage is quite clean and does not stink. The rooms are well ventilated.

07. The sorted waste is sent to the compact.

08. At first glance it seems simple. In fact, each technology node is unique expensive equipment, which is required for maintenance of first-class professionals.

09. This technology allows a small yard of debris removed from the 70% of useful products, 25% of which is the energy fuel that is used in concrete plants.

10. Under the useful products is understood everything that could further poison for processing. This molded plastic, paper, metal.

11. At the moment, the sorting plant can let through about 100 thousand tons of garbage a year. That's about 10% of the total volume of transported Autopark №1. Across the St. Petersburg this proportion is even lower. The Flax. field there is nothing like it, not to mention the processing. Garbage in the best case just buried in landfills. Despite the high cost of equipment for a fairly short period of time, this mini-factory came to self-sufficiency. If such an approach for waste disposal, which in Europe has long been the standard we are used everywhere around the world will be cleaner.

Source: s01101.livejournal.com