1712

How do the reindeer sausage? (54 photos)

Well-known blogger visited at the factory and saw with my own eyes how to prepare meat products of venison.

Sausage and meat products from the real meat of the deer there! No preservatives or artificial additives, I am convinced personally in the past weekend in the city of Naryan-Mar, the capital of the Nenets Autonomous District, and is the city above the Arctic Circle. We visited on the tour at the factory for the production of meat from venison, where we were told and showed the process from the bottom up canned. Reindeer herding and fishing - is the main occupation of the indigenous peoples of the north. Engaged in reindeer herding ancestors of today's Nenets, in Soviet times, traditional nomadic herding reindeer tried to change, but now everything has returned to the traditions of their ancestors. The NAO 42tys residents and 180tys deer that are on natural grazing in the vast expanses of tundra in the meat-packing plant meat is delivered by helicopter Mi-26 (!), The largest in the world! There are no GMOs and polfabrikatov, everything here - absolutely natural and natural! As a child I liked best the fourth (green) is the Children's Encyclopedia "technology and production", this volume was dedicated to all sorts of technological processes and to one of the pages was painted a fascinating comic with a cow in the top and a tin of corned beef in the end. And then, finally, I was able to see the process of cooking meat itself and make sure that there are natural products! Attention: report quite naturalistic, so if you are too impressionable and think sausage grows on trees in colored packages - more is better not to read.

Technical digression: in almost all areas of the enterprise lighting was inadequate for high-quality recording and flash I was not with him, so photo quality reportage and not bright sharp. Also, the white balance was incredibly difficult to correct, and black and white photos, I did not want to do. Let's start from the beginning ... with technology grazing deer. This is a map of the Nenets Autonomous District. Vertical color zoning refers to the region of a grazing deer hozyaytsvo throughout the year. The deer can not be kept on the farm, it is required nomadic life. Typically, a group of several herders (5-15) puts the tent for the period 3-4ned - 1, 5 months, surrounded by grazing deer, eating reindeer moss, which they dig even from under the snow. When lichen stocks in this area terminate - you need to change the location. Of course, in the process there are a lot of nuances, but very generalized fishing herders looks that way. Throughout the year every year.

In December-January slaughter of deer occurs. Most items slaughter (which are located in the villages) no refrigeration units, so freezing occurs naturally. As I wrote above, the number of reindeer in the NAO is 180tys deer culling is carried out annually 30-35tys deer. 70-80% of the downhole contingent - the deer up to 1 year. For comparison: in the 70s of the last century in the NAO annual slaughter 60-70tys deer. Slaughter is as follows: in the room at the same time blow in the frontal region of 8-10 stunned deer, then opened the large vessels of the neck and the carcasses are hung upside down on the line for the suspension procedure bleeding within 5-10 minutes. Bleeding - this is the most important process that affects the quality of electric myasa.Oglushenie not carried out. Then the processing of carcasses, skinning and internal organs, and the carcass is frozen in the natural winter conditions. Due to low temperatures (-25-35) water crystals in the muscle fibers are small and the meat after thawing retains juiciness. A full-frozen carcasses at these lower temperatures - 10-12 hours. On the question of "how waste is disposed of" - we were told that burn. At the moment, negotiations are underway with the Chinese for sampling some of the ingredients - antlers and the secret of the pancreas for the production of cosmetics and medicinal products, but it is all under discussion in view of the complex technological point - items removed from the bottom of Naryan-Mar. Frozen deer carcasses are removed from settlements in the tundra by helicopter Mi-26 is the largest serine transport helicopter in the world! I wrote about it here. One hour of the Mi-26 is 670 thousand rubles / hour capacity is 18 tons. When the purchase price of 125 rubles per 1 kg venison, the value of its helicopter transportation is still 90 rubles / kg !!! And other options to get to the remote regions of the county lacks. There are no roads or winter roads! During the winter, a helicopter makes 20-25 of flights in different regions where centralized dumped meat on snowmobiles from smaller villages or deer-fit yourself into major points of the face. And there is a flight of 1 hour, and there are flights for 5-6 hours. The turnover of the plant is 900 tons of venison in a year. 450 tons imported by helicopter and 450 - by road on winter roads. Kobinat of "Meats" - the only one in the county. Total for the season takes place slaughter 1000-1100 tons, 900 - collects and processes the meat and 100-150 is bought by the local population and is used locally for their own needs. This is the Mi-26 Squadron Naryan Mar Airport Naryan-Mar:

In the meat packing plant carcasses stored in freezers at -18. Actually in the winter there is an accumulation of the feedstock for the whole year of work.

Defrosting takes place in a special room with hot steam. Complete defrosting occurs within 8-10 hours, then washed the carcass right in this chamber:

Then the carcasses are transported to the boning hall, where the cutting: one boning plant cut up carcasses 35-45, where they are transported by crane. The average weight of the carcass of a deer 1 - 30-35kg.

Note the glove-armor:

Canned "Venison stew": Consists of natural pieces of reindeer meat, spices, herbs, salt and pepper, and fat. The meat mixture is cooking stew - only fresh landslides and zhilovanoe (removal of large veins, cartilage and blood vessels), which is the process of cooking in the morning boning and meat departments. A process of preparing themselves canned begins at 14.00. The meat mixture and remaining ingredients are loaded into the banks, rolled here:

Then the banks are loaded into the conveyor and placed in the Italian avtokalav rolled straight into the (!) Banks, and are heated to 120 degrees for 20 minutes. Exposure Temperature 120 degrees sostavyalet 55 minutes. Then cool down for 20 minutes. Those. Formula fighting and sterilization - a «20-55-20»:

Then the truck rolls out from the autoclave and allowed to cool for a day, then to the implementation of each batch is kept at the plant for 11 days. During this time, each party takes control of bacteriological Arkhangelsk, 3 banks from each batch sent to the laboratory aircraft. The day produced 1500 cans.

Now go through the various offices slaughterhouse, because here produce 50 kinds of products! Sausage department: For the production of sausages it uses minced: venison - up to 80%, pork (bacon) - 15%, soya - up to 5%. Sausage can only be venison, as it will be tough and tasteless. But, more importantly, the sausage is really out of the meat! Pork and beef are imported 400 tons from the central regions of Russia, from which the meat-packing plant produces as a standalone product or in addition to the venison sausage.

and further to the drying-smoking chamber:

In the same chamber fall deer ribs:

And here is how to prepare a multilayer bacon:

Spices between layers:

By the way, there is a special room myaskokombinate with spices, the smell here as bazaar:

This workshop formed bags with fresh meat for freezing:

Finally, cutlet department! Cutting different types of meat to form a stuffing:

Add the bread:

Mix:

And we get the stuffing:

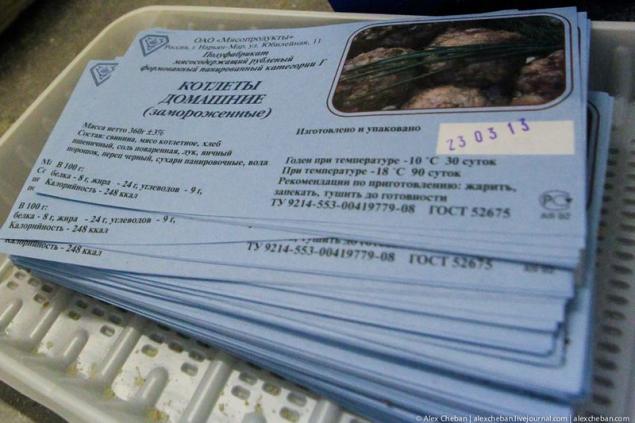

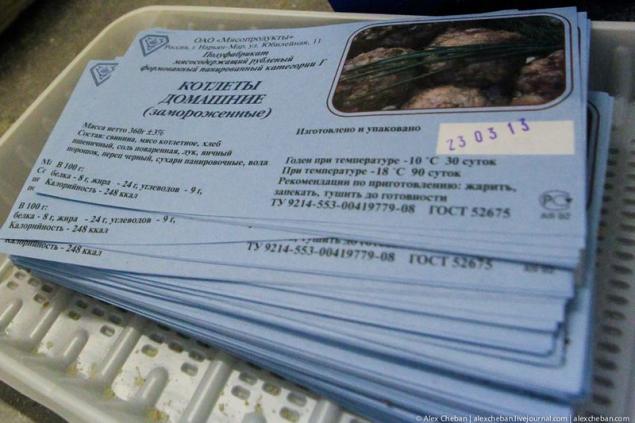

Next formed patties of minced meat, breading and packed:

For an amazing tour, I thank the chief technologist of the plant, and the name I have not recorded on tape :(

And the General Director of "Meats" Nazarenko Yury:

Chips jerked venison:

All fantastically tasty!

Source: alexcheban.livejournal.com

Sausage and meat products from the real meat of the deer there! No preservatives or artificial additives, I am convinced personally in the past weekend in the city of Naryan-Mar, the capital of the Nenets Autonomous District, and is the city above the Arctic Circle. We visited on the tour at the factory for the production of meat from venison, where we were told and showed the process from the bottom up canned. Reindeer herding and fishing - is the main occupation of the indigenous peoples of the north. Engaged in reindeer herding ancestors of today's Nenets, in Soviet times, traditional nomadic herding reindeer tried to change, but now everything has returned to the traditions of their ancestors. The NAO 42tys residents and 180tys deer that are on natural grazing in the vast expanses of tundra in the meat-packing plant meat is delivered by helicopter Mi-26 (!), The largest in the world! There are no GMOs and polfabrikatov, everything here - absolutely natural and natural! As a child I liked best the fourth (green) is the Children's Encyclopedia "technology and production", this volume was dedicated to all sorts of technological processes and to one of the pages was painted a fascinating comic with a cow in the top and a tin of corned beef in the end. And then, finally, I was able to see the process of cooking meat itself and make sure that there are natural products! Attention: report quite naturalistic, so if you are too impressionable and think sausage grows on trees in colored packages - more is better not to read.

Technical digression: in almost all areas of the enterprise lighting was inadequate for high-quality recording and flash I was not with him, so photo quality reportage and not bright sharp. Also, the white balance was incredibly difficult to correct, and black and white photos, I did not want to do. Let's start from the beginning ... with technology grazing deer. This is a map of the Nenets Autonomous District. Vertical color zoning refers to the region of a grazing deer hozyaytsvo throughout the year. The deer can not be kept on the farm, it is required nomadic life. Typically, a group of several herders (5-15) puts the tent for the period 3-4ned - 1, 5 months, surrounded by grazing deer, eating reindeer moss, which they dig even from under the snow. When lichen stocks in this area terminate - you need to change the location. Of course, in the process there are a lot of nuances, but very generalized fishing herders looks that way. Throughout the year every year.

In December-January slaughter of deer occurs. Most items slaughter (which are located in the villages) no refrigeration units, so freezing occurs naturally. As I wrote above, the number of reindeer in the NAO is 180tys deer culling is carried out annually 30-35tys deer. 70-80% of the downhole contingent - the deer up to 1 year. For comparison: in the 70s of the last century in the NAO annual slaughter 60-70tys deer. Slaughter is as follows: in the room at the same time blow in the frontal region of 8-10 stunned deer, then opened the large vessels of the neck and the carcasses are hung upside down on the line for the suspension procedure bleeding within 5-10 minutes. Bleeding - this is the most important process that affects the quality of electric myasa.Oglushenie not carried out. Then the processing of carcasses, skinning and internal organs, and the carcass is frozen in the natural winter conditions. Due to low temperatures (-25-35) water crystals in the muscle fibers are small and the meat after thawing retains juiciness. A full-frozen carcasses at these lower temperatures - 10-12 hours. On the question of "how waste is disposed of" - we were told that burn. At the moment, negotiations are underway with the Chinese for sampling some of the ingredients - antlers and the secret of the pancreas for the production of cosmetics and medicinal products, but it is all under discussion in view of the complex technological point - items removed from the bottom of Naryan-Mar. Frozen deer carcasses are removed from settlements in the tundra by helicopter Mi-26 is the largest serine transport helicopter in the world! I wrote about it here. One hour of the Mi-26 is 670 thousand rubles / hour capacity is 18 tons. When the purchase price of 125 rubles per 1 kg venison, the value of its helicopter transportation is still 90 rubles / kg !!! And other options to get to the remote regions of the county lacks. There are no roads or winter roads! During the winter, a helicopter makes 20-25 of flights in different regions where centralized dumped meat on snowmobiles from smaller villages or deer-fit yourself into major points of the face. And there is a flight of 1 hour, and there are flights for 5-6 hours. The turnover of the plant is 900 tons of venison in a year. 450 tons imported by helicopter and 450 - by road on winter roads. Kobinat of "Meats" - the only one in the county. Total for the season takes place slaughter 1000-1100 tons, 900 - collects and processes the meat and 100-150 is bought by the local population and is used locally for their own needs. This is the Mi-26 Squadron Naryan Mar Airport Naryan-Mar:

In the meat packing plant carcasses stored in freezers at -18. Actually in the winter there is an accumulation of the feedstock for the whole year of work.

Defrosting takes place in a special room with hot steam. Complete defrosting occurs within 8-10 hours, then washed the carcass right in this chamber:

Then the carcasses are transported to the boning hall, where the cutting: one boning plant cut up carcasses 35-45, where they are transported by crane. The average weight of the carcass of a deer 1 - 30-35kg.

Note the glove-armor:

Canned "Venison stew": Consists of natural pieces of reindeer meat, spices, herbs, salt and pepper, and fat. The meat mixture is cooking stew - only fresh landslides and zhilovanoe (removal of large veins, cartilage and blood vessels), which is the process of cooking in the morning boning and meat departments. A process of preparing themselves canned begins at 14.00. The meat mixture and remaining ingredients are loaded into the banks, rolled here:

Then the banks are loaded into the conveyor and placed in the Italian avtokalav rolled straight into the (!) Banks, and are heated to 120 degrees for 20 minutes. Exposure Temperature 120 degrees sostavyalet 55 minutes. Then cool down for 20 minutes. Those. Formula fighting and sterilization - a «20-55-20»:

Then the truck rolls out from the autoclave and allowed to cool for a day, then to the implementation of each batch is kept at the plant for 11 days. During this time, each party takes control of bacteriological Arkhangelsk, 3 banks from each batch sent to the laboratory aircraft. The day produced 1500 cans.

Now go through the various offices slaughterhouse, because here produce 50 kinds of products! Sausage department: For the production of sausages it uses minced: venison - up to 80%, pork (bacon) - 15%, soya - up to 5%. Sausage can only be venison, as it will be tough and tasteless. But, more importantly, the sausage is really out of the meat! Pork and beef are imported 400 tons from the central regions of Russia, from which the meat-packing plant produces as a standalone product or in addition to the venison sausage.

and further to the drying-smoking chamber:

In the same chamber fall deer ribs:

And here is how to prepare a multilayer bacon:

Spices between layers:

By the way, there is a special room myaskokombinate with spices, the smell here as bazaar:

This workshop formed bags with fresh meat for freezing:

Finally, cutlet department! Cutting different types of meat to form a stuffing:

Add the bread:

Mix:

And we get the stuffing:

Next formed patties of minced meat, breading and packed:

For an amazing tour, I thank the chief technologist of the plant, and the name I have not recorded on tape :(

And the General Director of "Meats" Nazarenko Yury:

Chips jerked venison:

All fantastically tasty!

Source: alexcheban.livejournal.com