8222

Toy boat

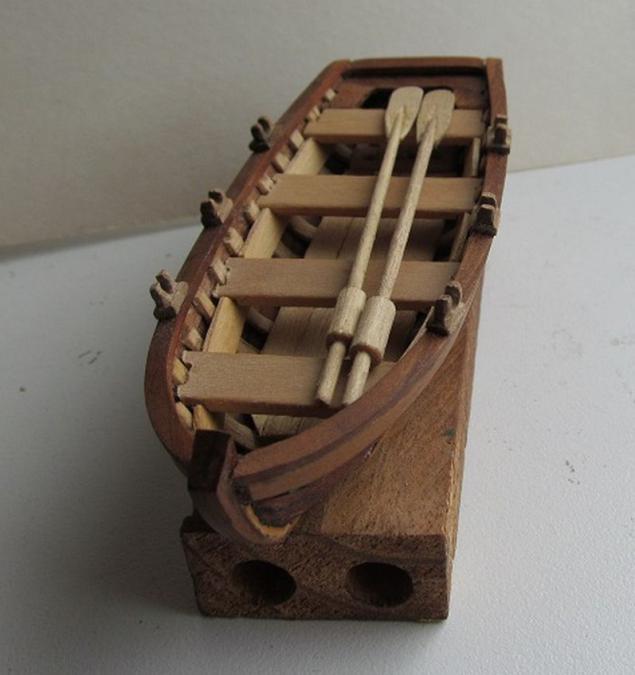

Excellent instruction and photo-author who decided to make a toy boat with their hands. Look further. That boat that came to the magazine "Great sailing" I, like many colleagues, shipbuilders, immediately I did not like. "Take a piece of silumin and paint it the color of the wood" - I need it, this "museum-quality model"! It was decided to do everything well. Looked drawings models boat from any other set. Taken from the set of "Victory" of the same Diagostini (hoping to take some time and for the ship). There's a different scale, but also on the boat, the boat more. And if the bench to put through one and omit unnecessary rig here, you get the most it.

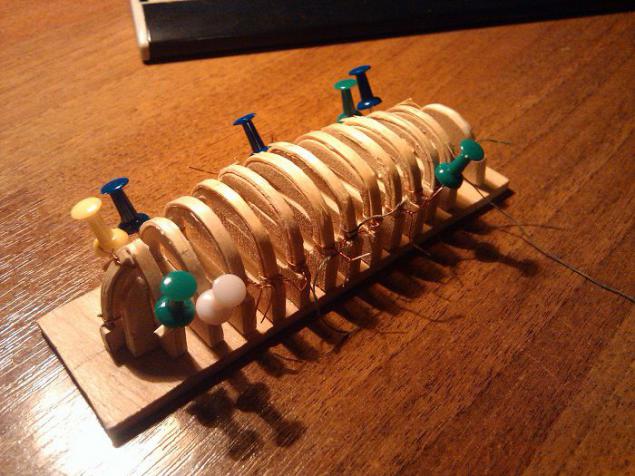

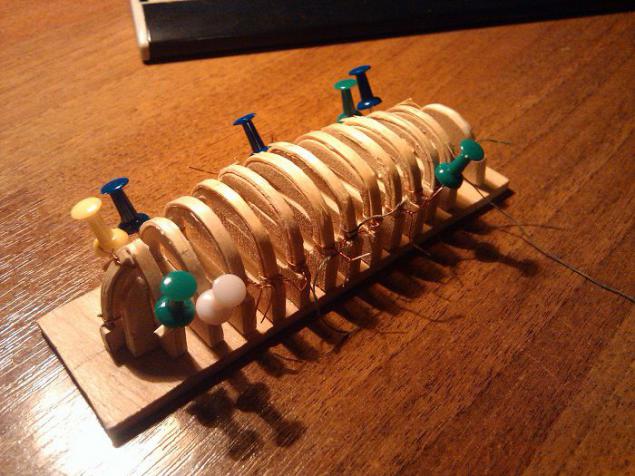

Coined as "kill two birds with one stone." Sawed plywood frames "Victoria", set on the plate (as per instructions). The resulting semi-finished product used as a template for making boats for Galleon. Someday plywood frames will be connected shell and become boat to Victoria. Although before it happens, can be used as a matrix for many times.

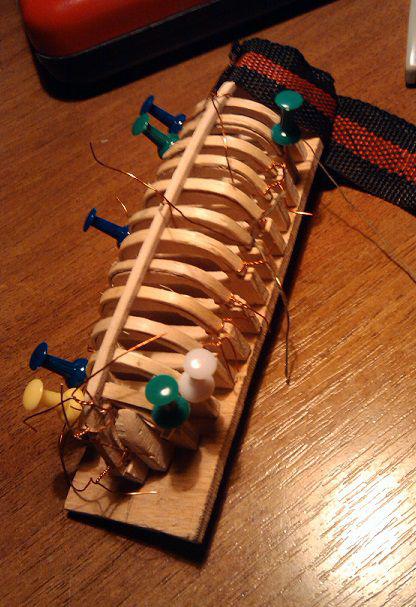

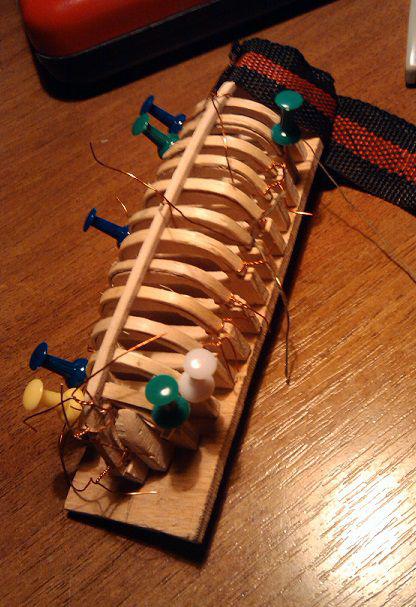

So, take wooden sticks for stirring coffee, hold for a couple and Gnehm. There are different techniques: soak in hot water and bending on the matrix; You can keep steaming and bending (better right in the jet of steam), and then to the matrix primatyvat for drying; You can soak and then smoothing iron or a soldering iron in place. In any case, future frames (the edges of the ship) it is better to fix. In this case, the wire came. If a matrix is not planned to do a boat, no holes in the plywood sawing and then just have pinned down (stationery nails).

Later impose keel.

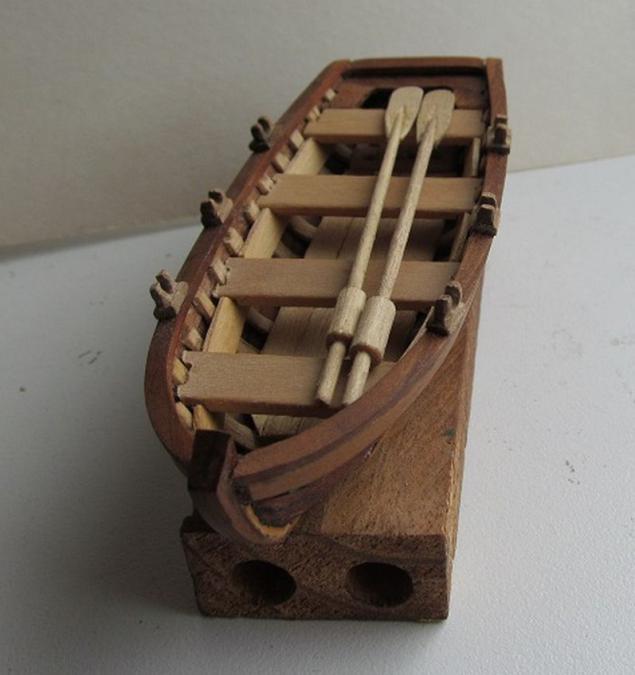

Begin lining. References such as a face and a ship. Do not turn up his nose at the first belt casing (near the keel) up. Share the remaining length of the frame in equal parts and navigate to these marks with a thickness of cladding boards in different sections. In general, each board is narrowed on both sides. A couple of bends. Is attached. Over the last (top) of a number of skin impose another bar (barhout).

Cut the nose of the keel (somehow too nazavaetsya), "railing". You should also increase the aft keel (keel should form a straight.

Benches made of ice cream sticks. The flooring of the same sticks for coffee. Grille at the stern - another story. Sheathing plavstredstva skins. Prosmalivanie simulated as follows: A mixture of the PVA and the black ink is applied using a syringe into the slit. Remove excess skin. Mark and ink very well penetrate into the wood, so accuracy will not be superfluous.

The final finish - Floor linseed oil

In a set of "Great sailing" boat oars is not completed. In "Victor" is, but metal. And, moreover, cast not the best way. Did not want to copy. And why do the paddle tin? Sharpen - alas no lathe. But was easy to manufacture them and improvised.

For the manufacture of oars need toothpicks, chopsticks manicure (cuticle), sticks for stirring coffee. Well, some tools.

Saw off from manicure sticks (mandarin tree) about a centimeter. Drilled through along the axis. Since the wood fibers are strictly along the axis, the opening does not lead to side. But it is still best to drill from both sides. Sharp tips toothpicks bites. Depending on the desired length of the paddle can be used a toothpick. But I needed a little longer. Joint tucked away in the middle of the widest part.

Then quite subtle point: it is necessary to saw through a slit in the floss under the "blade" paddles. I performed this lobzokom. Surprisingly it was easy. Apparently, it's worth thanks for the properties of bamboo (or from which there is the Chinese sharpen toothpicks). And then Scrollsaw of sticks for coffee blade. The blade has a thickness approximately the same as the diameter of the floss. So we'll have to do at the junction of the slots. I found this to chisel. Sadim glue. And actually everything.

Source: master-klass.livejournal.com

Coined as "kill two birds with one stone." Sawed plywood frames "Victoria", set on the plate (as per instructions). The resulting semi-finished product used as a template for making boats for Galleon. Someday plywood frames will be connected shell and become boat to Victoria. Although before it happens, can be used as a matrix for many times.

So, take wooden sticks for stirring coffee, hold for a couple and Gnehm. There are different techniques: soak in hot water and bending on the matrix; You can keep steaming and bending (better right in the jet of steam), and then to the matrix primatyvat for drying; You can soak and then smoothing iron or a soldering iron in place. In any case, future frames (the edges of the ship) it is better to fix. In this case, the wire came. If a matrix is not planned to do a boat, no holes in the plywood sawing and then just have pinned down (stationery nails).

Later impose keel.

Begin lining. References such as a face and a ship. Do not turn up his nose at the first belt casing (near the keel) up. Share the remaining length of the frame in equal parts and navigate to these marks with a thickness of cladding boards in different sections. In general, each board is narrowed on both sides. A couple of bends. Is attached. Over the last (top) of a number of skin impose another bar (barhout).

Cut the nose of the keel (somehow too nazavaetsya), "railing". You should also increase the aft keel (keel should form a straight.

Benches made of ice cream sticks. The flooring of the same sticks for coffee. Grille at the stern - another story. Sheathing plavstredstva skins. Prosmalivanie simulated as follows: A mixture of the PVA and the black ink is applied using a syringe into the slit. Remove excess skin. Mark and ink very well penetrate into the wood, so accuracy will not be superfluous.

The final finish - Floor linseed oil

In a set of "Great sailing" boat oars is not completed. In "Victor" is, but metal. And, moreover, cast not the best way. Did not want to copy. And why do the paddle tin? Sharpen - alas no lathe. But was easy to manufacture them and improvised.

For the manufacture of oars need toothpicks, chopsticks manicure (cuticle), sticks for stirring coffee. Well, some tools.

Saw off from manicure sticks (mandarin tree) about a centimeter. Drilled through along the axis. Since the wood fibers are strictly along the axis, the opening does not lead to side. But it is still best to drill from both sides. Sharp tips toothpicks bites. Depending on the desired length of the paddle can be used a toothpick. But I needed a little longer. Joint tucked away in the middle of the widest part.

Then quite subtle point: it is necessary to saw through a slit in the floss under the "blade" paddles. I performed this lobzokom. Surprisingly it was easy. Apparently, it's worth thanks for the properties of bamboo (or from which there is the Chinese sharpen toothpicks). And then Scrollsaw of sticks for coffee blade. The blade has a thickness approximately the same as the diameter of the floss. So we'll have to do at the junction of the slots. I found this to chisel. Sadim glue. And actually everything.

Source: master-klass.livejournal.com