997

Installation of the warm floor in the screed

A screed is a layer of concrete that is laid on top of a heat-insulating layer when installing a warm floor system. Equipping screed, you should choose its thickness correctly: if it is too large, it will adversely affect the heat transfer. And insufficient thickness will lead to cracks and pressing of the floor covering.

Installation rules

Most often, the warm floor is mounted on the old base. A layer of thermal insulation is placed on top. This rule is relevant when arranging both electric and hydraulic warm floors. Then the pipeline or cables are laid. And at the end, a screed is installed with a thickness of 3 to 5 cm - this allows you to achieve rapid warming up and avoid alternation of warm and cold zones. If the installation conditions do not allow you to make a screed of the desired thickness, you should add a universal plasticizer to the solution.

Important: when installing a warm floor in a screed, it is necessary to take into account that the pipeline and electrical cables are relatively soft materials. To increase the reliability of the system, it is recommended to make holes in each m2 area and leave a free strip of 10 - 15 cm between the insulator and the warm floor. Another 1 option is to use a self-leveling mixture (this will increase the resistance of the base to loads).

Step-by-step instruction

Installation of the warm floor under the screed is performed in several stages:

Installation rules

Most often, the warm floor is mounted on the old base. A layer of thermal insulation is placed on top. This rule is relevant when arranging both electric and hydraulic warm floors. Then the pipeline or cables are laid. And at the end, a screed is installed with a thickness of 3 to 5 cm - this allows you to achieve rapid warming up and avoid alternation of warm and cold zones. If the installation conditions do not allow you to make a screed of the desired thickness, you should add a universal plasticizer to the solution.

Important: when installing a warm floor in a screed, it is necessary to take into account that the pipeline and electrical cables are relatively soft materials. To increase the reliability of the system, it is recommended to make holes in each m2 area and leave a free strip of 10 - 15 cm between the insulator and the warm floor. Another 1 option is to use a self-leveling mixture (this will increase the resistance of the base to loads).

Step-by-step instruction

Installation of the warm floor under the screed is performed in several stages:

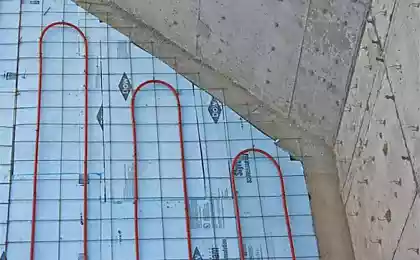

- A heater lies over the draft screed. We recommend fixing it with tape, glue and dowels.

- Reinforced netting is being laid. It not only increases the rigidity of the structure, but also simplifies markings when laying pipes, cables. Like the insulation, the net is attached to the base.

- The damper tape is being installed. It helps to reduce the coefficient of linear stretching, and also improves the heat and sound insulation properties of the system.

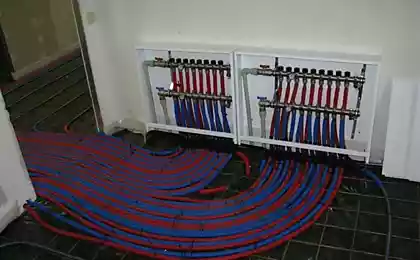

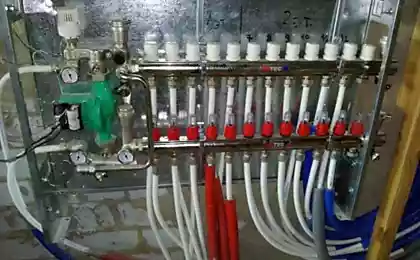

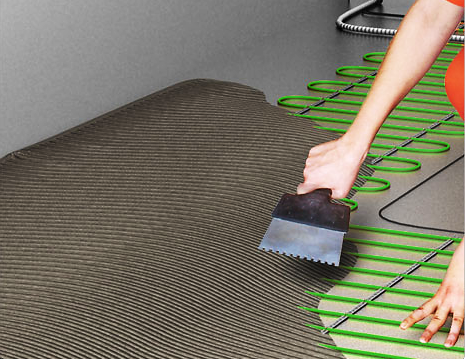

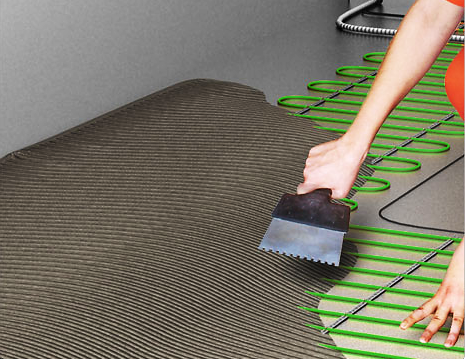

- On top of the damper tape, elements of warm floors are installed and connected to the coolant.

- On top of the pipeline and cables is laid another layer of screed.

- When the solution dries, you can install the finishing floor covering.