550

How to save your money teplocenter radiators

Teplocentral radiator – new type of heating device with high efficiency. The high efficiency of the radiator is the principle of steam heating, namely the evaporation and subsequent condensation of the steam of the secondary coolant. Applying teplocenter radiators you can achieve significant savings in energy, which each heating season only added to the price. This effect is achieved due to the advantages of our radiators compared to classic radiators.

Offer more details focus on the question of efficiency and economy teplocenter radiators.

1. Radiant heat.

Teplocenter radiators have a uniform heating area, there is not any cold spots. The uniformity of heating the entire surface teplokontrol radiator at different temperatures is confirmed by thermal imaging survey during the laboratory tests in NTUU "KPI". Notable is the fact that even heating occurs in the low-temperature operating modes of the radiator.

Thus, radiant heat is the primary thermal radiation teplokontrol radiator. A well known fact that radiant heat is the most comfortable and acceptable to the human body, because we all feel the warmth of fire and sun, even in cold weather. The main advantage of radiant heating is that the heating device heats the air and objects which in turn heat the room. According to the European standards in the room with radiant heating, the temperatures average 2°C lower than conventional, convective heating, and lowering the room temperature by 1°C gives up to 7 % savings of energy. Thus, only through the effective application of the radiant energy radiator, and lowering the temperature in a heated room about 2°C will save energy at 12 – 14 %.

2. The differential temperature of the coolant passing through the radiator.

In traditional steel and aluminum radiators, the temperature difference of the coolant at the inlet and outlet in the device is about 10 – 15°C due to the heat capacity of the coolant and the speed of its movement in the radiator. In order that the radiator has developed a thermal power of heat generator heated water, or other coolant, to cool, passing through him, and to give some part of the energy of the heated room. Data on the temperature differential of the coolant and heat output of the radiator manufacturer specifies in the technical passport for the product, based on the test Protocol. Tests of thermal equipment are conducted in specially equipped labs equipped with climate chambers. In accordance with the test Protocol teplokontrol radiator, the temperature drop of the coolant when passing through the test sample, TKR 980 ( radiator length 1 m, a height of 575 mm and a thickness of 55 mm) was from 2 to 5°C and the heater power is about 700 W/m2, which is 75 – 80% higher than traditional radiators. Laboratory studies teplokontrol radiator was carried out in the Certification testing center of heating equipment (EGF, SIZOO) in Kiev. The tests were carried out in accordance with DSTU B V. 2.5-3-95 thus, in accordance with European standard EN 442-2, at various values of the temperature and flow of coolant.

The reduction of temperature drop of the coolant during passage of the heating from 15°C to 5°C, with no loss of heat output of a radiator, allows to reduce the consumption of energy by 10 %, because the boiler need to heat the return line not the 15 – 20°C, and only 5 – 10°C. This operating temperature significantly reduces the time of operation of the boiler, which leads to additional savings.

3. Reduction of quantity of coolant.

Teplokontrol the radiator for correct operation requires ten times less coolant than steel or aluminum radiator. Indeed, in our case, the bulk heating performs secondary coolant. Now let us return to the subject sample TKR 980. This radiator contains a total of 200 grams of water, while in section glassware forming aluminum, the same size as 4л. According to the course of physics we know that for heating the small quantity of water you need to make a small amount of energy. Let's calculate the amount of heat energy which is needed to heat 200 grams and 4L of coolant from 65 to 75°C.

Q=c*m*(t1-t2)

Q1 = 4200*0,2*(75-65)= 8400 J = 2.33 W

Q2 = 4200*4*(75-65)= 168000 J = 46.6 Watts.

As can be seen from the calculation, the amount of energy for heating small quantity of the coolant many times less. This fact affects not only the economy but also on the inertia of the heating system – the less coolant, the less time and energy required for its heating, and the faster the radiator starts to transfer heat to the room.

Of course, the reader could be the outrage about such a relatively calculate, because the less coolant, the faster it will cool down and will give only the amount of energy which was delivered to him – no more and no less. I completely agree with this statement. But there is one point which I will discuss in the following paragraph.

4. The use of steam power.

Based on the work teplokontrol radiator is the principle of using the energy released in condensing steam of the secondary coolant. When calculating the amount spent and received energy for heating the coolant, I deliberately did not raise the issue of energy use secondary coolant, although this component is the key to the effectiveness and power of our product.

When passing through the traditional radiator, the coolant gives only part of its energy, cools down to a certain number of degrees, often for efficient operation of radiator heating systems, this value ranges from 10°C to 15°C, increasing the Delta temperature obtained cold "return", reducing the need to increase the flow and speed of flow through the pipes, which entails the necessity of increasing diameters, the performance of the circulation pump, which is not always possible and economically feasible.

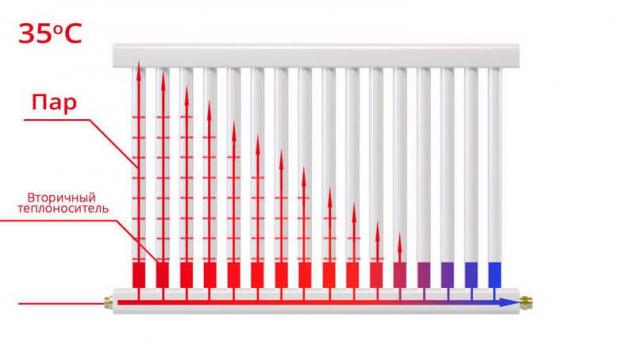

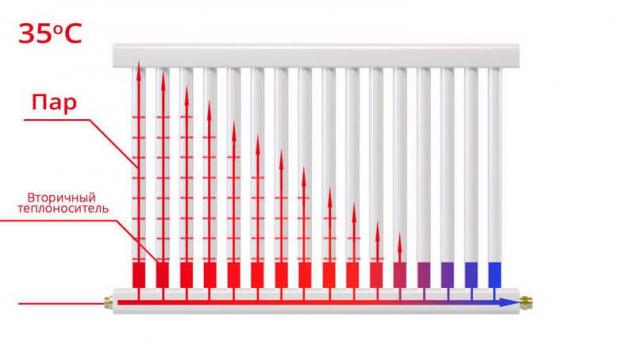

So what happens when you work teplokontrol radiator? Feeding the primary radiator coolant, we call the process of boiling of the secondary coolant in the bottom of the radiator, followed by evaporation. Thus by creating a certain pressure value which is below atmospheric, the boiling process begins at 35°C. Increasing the temperature of the primary coolant, the temperature of steam inside the radiator, thus increasing the speed and intensity of evaporation of the liquid secondary coolant.

When this condensation occurs on the inner walls of the radiator that transfer heat to the phase transition, released by condensation in a heated room. The condensate under the action of gravity flows into the evaporation zone, completing the process of heat transfer. The increase in temperature of the primary coolant, or if to say easier, increase the flow temperature on the boiler, leads to increased intensity and frequency of the process of evaporation and condensation inside teplokontrol radiator, which in turn leads to an increase in its thermal capacity. Therefore, the temperature difference inside teplokontrol radiator is at 10– 15°C, and the difference between the steam temperature and the temperature of the heated space (condensation temperature), feeding the radiator with coolant with a temperature of 65°C and room temperature of 20°C Delta temperature will be 45°C, which is unattainable for the normal radiators.

Teplocentral radiator – brand new heating appliance to significantly reduce the amount of consumed energy due to a number of advantages. Primarily due to the working principle which is fundamentally different from the traditional radiators. Applying teplocenter radiators for heating of premises of all types, both residential and industrial, You can reduce energy costs up to 30%. published

Source: energy24.com.ua/index.php?route=blog/article&article_id=75

Offer more details focus on the question of efficiency and economy teplocenter radiators.

1. Radiant heat.

Teplocenter radiators have a uniform heating area, there is not any cold spots. The uniformity of heating the entire surface teplokontrol radiator at different temperatures is confirmed by thermal imaging survey during the laboratory tests in NTUU "KPI". Notable is the fact that even heating occurs in the low-temperature operating modes of the radiator.

Thus, radiant heat is the primary thermal radiation teplokontrol radiator. A well known fact that radiant heat is the most comfortable and acceptable to the human body, because we all feel the warmth of fire and sun, even in cold weather. The main advantage of radiant heating is that the heating device heats the air and objects which in turn heat the room. According to the European standards in the room with radiant heating, the temperatures average 2°C lower than conventional, convective heating, and lowering the room temperature by 1°C gives up to 7 % savings of energy. Thus, only through the effective application of the radiant energy radiator, and lowering the temperature in a heated room about 2°C will save energy at 12 – 14 %.

2. The differential temperature of the coolant passing through the radiator.

In traditional steel and aluminum radiators, the temperature difference of the coolant at the inlet and outlet in the device is about 10 – 15°C due to the heat capacity of the coolant and the speed of its movement in the radiator. In order that the radiator has developed a thermal power of heat generator heated water, or other coolant, to cool, passing through him, and to give some part of the energy of the heated room. Data on the temperature differential of the coolant and heat output of the radiator manufacturer specifies in the technical passport for the product, based on the test Protocol. Tests of thermal equipment are conducted in specially equipped labs equipped with climate chambers. In accordance with the test Protocol teplokontrol radiator, the temperature drop of the coolant when passing through the test sample, TKR 980 ( radiator length 1 m, a height of 575 mm and a thickness of 55 mm) was from 2 to 5°C and the heater power is about 700 W/m2, which is 75 – 80% higher than traditional radiators. Laboratory studies teplokontrol radiator was carried out in the Certification testing center of heating equipment (EGF, SIZOO) in Kiev. The tests were carried out in accordance with DSTU B V. 2.5-3-95 thus, in accordance with European standard EN 442-2, at various values of the temperature and flow of coolant.

The reduction of temperature drop of the coolant during passage of the heating from 15°C to 5°C, with no loss of heat output of a radiator, allows to reduce the consumption of energy by 10 %, because the boiler need to heat the return line not the 15 – 20°C, and only 5 – 10°C. This operating temperature significantly reduces the time of operation of the boiler, which leads to additional savings.

3. Reduction of quantity of coolant.

Teplokontrol the radiator for correct operation requires ten times less coolant than steel or aluminum radiator. Indeed, in our case, the bulk heating performs secondary coolant. Now let us return to the subject sample TKR 980. This radiator contains a total of 200 grams of water, while in section glassware forming aluminum, the same size as 4л. According to the course of physics we know that for heating the small quantity of water you need to make a small amount of energy. Let's calculate the amount of heat energy which is needed to heat 200 grams and 4L of coolant from 65 to 75°C.

Q=c*m*(t1-t2)

Q1 = 4200*0,2*(75-65)= 8400 J = 2.33 W

Q2 = 4200*4*(75-65)= 168000 J = 46.6 Watts.

As can be seen from the calculation, the amount of energy for heating small quantity of the coolant many times less. This fact affects not only the economy but also on the inertia of the heating system – the less coolant, the less time and energy required for its heating, and the faster the radiator starts to transfer heat to the room.

Of course, the reader could be the outrage about such a relatively calculate, because the less coolant, the faster it will cool down and will give only the amount of energy which was delivered to him – no more and no less. I completely agree with this statement. But there is one point which I will discuss in the following paragraph.

4. The use of steam power.

Based on the work teplokontrol radiator is the principle of using the energy released in condensing steam of the secondary coolant. When calculating the amount spent and received energy for heating the coolant, I deliberately did not raise the issue of energy use secondary coolant, although this component is the key to the effectiveness and power of our product.

When passing through the traditional radiator, the coolant gives only part of its energy, cools down to a certain number of degrees, often for efficient operation of radiator heating systems, this value ranges from 10°C to 15°C, increasing the Delta temperature obtained cold "return", reducing the need to increase the flow and speed of flow through the pipes, which entails the necessity of increasing diameters, the performance of the circulation pump, which is not always possible and economically feasible.

So what happens when you work teplokontrol radiator? Feeding the primary radiator coolant, we call the process of boiling of the secondary coolant in the bottom of the radiator, followed by evaporation. Thus by creating a certain pressure value which is below atmospheric, the boiling process begins at 35°C. Increasing the temperature of the primary coolant, the temperature of steam inside the radiator, thus increasing the speed and intensity of evaporation of the liquid secondary coolant.

When this condensation occurs on the inner walls of the radiator that transfer heat to the phase transition, released by condensation in a heated room. The condensate under the action of gravity flows into the evaporation zone, completing the process of heat transfer. The increase in temperature of the primary coolant, or if to say easier, increase the flow temperature on the boiler, leads to increased intensity and frequency of the process of evaporation and condensation inside teplokontrol radiator, which in turn leads to an increase in its thermal capacity. Therefore, the temperature difference inside teplokontrol radiator is at 10– 15°C, and the difference between the steam temperature and the temperature of the heated space (condensation temperature), feeding the radiator with coolant with a temperature of 65°C and room temperature of 20°C Delta temperature will be 45°C, which is unattainable for the normal radiators.

Teplocentral radiator – brand new heating appliance to significantly reduce the amount of consumed energy due to a number of advantages. Primarily due to the working principle which is fundamentally different from the traditional radiators. Applying teplocenter radiators for heating of premises of all types, both residential and industrial, You can reduce energy costs up to 30%. published

Source: energy24.com.ua/index.php?route=blog/article&article_id=75

Psychological resilience: How to learn not to break

Seizures - an important signal of the body about serious violations