1165

Heating system for the two-storey house

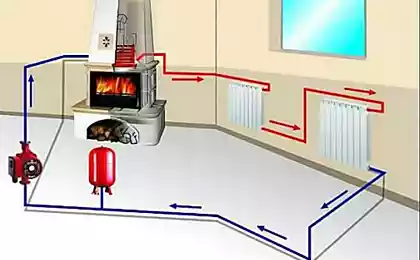

Today I'll tell you how we did the heating system on the first floor of a country house for from the oven with integrated heat exchanger.

2.Imeetsya oven (flue installed for a week ranshe- this will be a separate post) .This model furnace allows you to connect a maximum of 45 sections radiators, ie theoretically it was possible to make the system of two floors, but the budget was limited and it was decided at the first stage heat only the first floor.

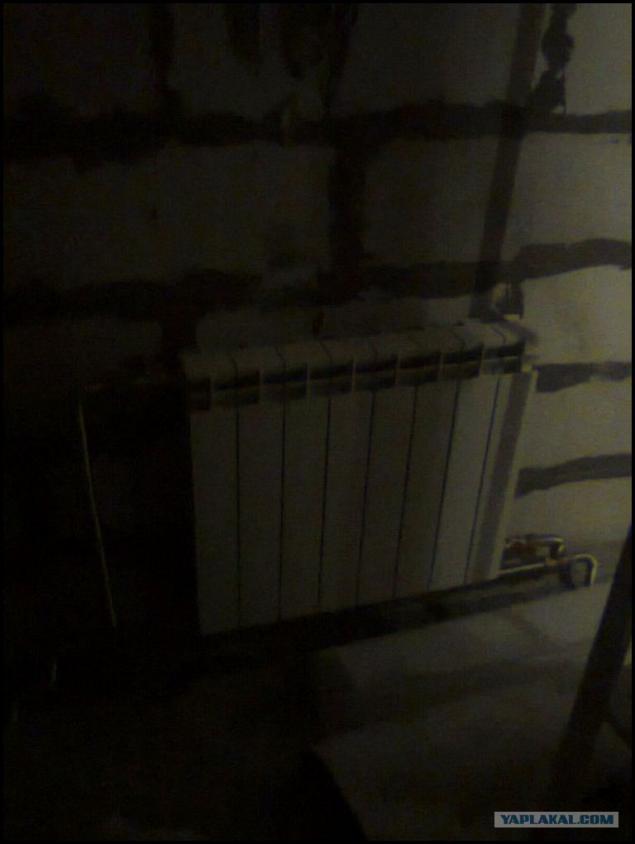

3.Pech rear view. Here we see the two fitting: the lower - the entrance, top - out. This will connect our radiators. In total, the system will have 3 batteries - 2 pcs. 8 sections, and 1 pc. 6 sections. Obogreem these radiators 1 living room, bathroom and hallway.

4.Vyhody on the stove - 1 inch. For the sealing of threaded connections use UNIPAK together with flax sanitary.

5.Nakruchivaem transition 3/4 dyuyma.T.k.v system will use a circulating pump We do not need a large cross-section of water pipe - will drive the coolant pump and a pipe with a smaller secheniem.Dyuymovye pipe should be used in systems with natural circulation.

6. When the installation using a flexible corrugated pipe Kofulso stainless stali.V roll - 30 meters. The rest of the package - easy to use for storage of automobile wheels, so do not cut the cover and gently untie.

7A's pipe itself. corrugated pipe made of stainless steel is a modern material for pipeline installation of almost any purpose: heating systems, hot and cold water, drain and serve any zhidkostey.Ona steel combines strength and flexibility of rubber hose. Only the pipe by displacement Kofulso not afraid and does not change its diameter, such as rubber or plastic.

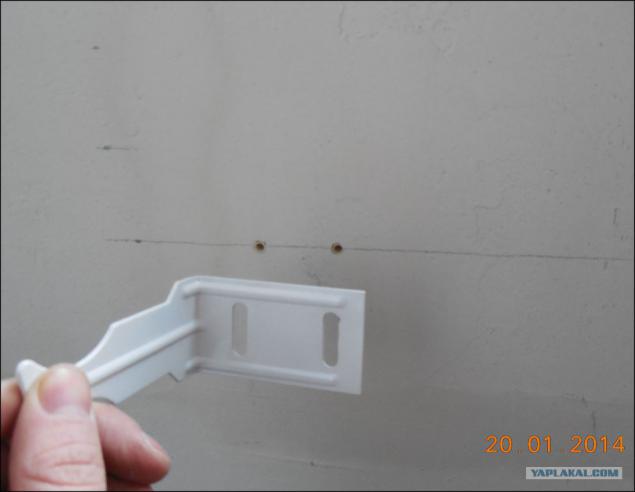

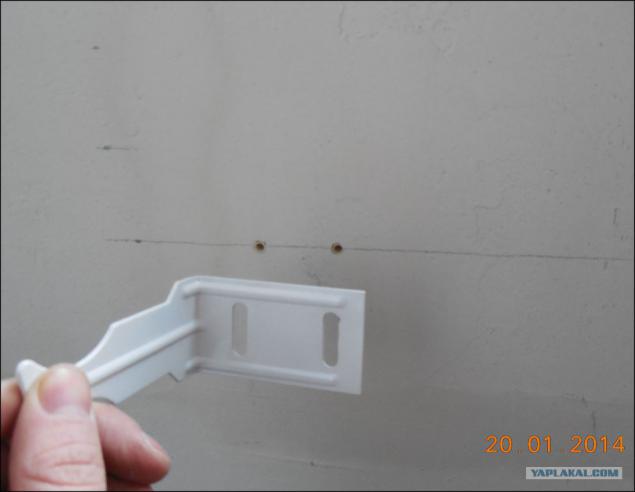

8.Perehodim the preparation of the site of attachment of radiators: mark up the holes with the expectation that the radiator appeared in the middle of the window and 15cm below the sill of the future.

9.Na this object wall of my foam-HITACHI easily coped worse when the walls betonnye- here already have to tinker with the hammer.

10. In the prepared hole anchor we exhaust spacer plastic nylon 6 NAT Sormat Sormat.

11.For embedding anchors using mallet STAYER PROFI 2052-90.Ona is a tool the size of 90 mm series PROFI, percussive element is made of rubber in black and has a cylindrical shape with flat sides and a metal handle.

12.Gotovo! And exactly in the intended place! Rare udacha.Povtoryaem 32 times.

13.Ustanavlivaem mount radiators.

14.Vse ready for the first radiator.

15.Proveryaem on urovnyu.V within tolerance ... so what could be there! - Perfect !!!

16.Teper proceed to the laying of track between batareyami.Nachnem with drilling sten.V arsenal could not find the right drill diameter and dliny.Prishlos out of the situation. First passes through the wall of a thin brown. The punch comes in.

17.A is now on both sides of the wall increase the hole to the desired diameter.

18.Prosovyvaem the resulting hole in the pipe.

19.Hotel a drink of water, it appears that while we worked hard, water has moved from liquid to solid and drink it in this form of the bottle neudobno.Poetomu continue to work.

20.Prodolzhaem pass through walls. This corner was littered with various nishtyak, so first had to move everything on the center of the room and free for a foothold.

21.Poka I practice the exercises with the hammer, a partner engaged in the preparation of radiators again using flax and Unipak cheat American, plugs and bleed screw.

22.Ne forget to seal all the threaded connections and the use of flax UNIPACK.

23.Trubu Kofulso cut using a special cutter or as an option - you can use the grinder.

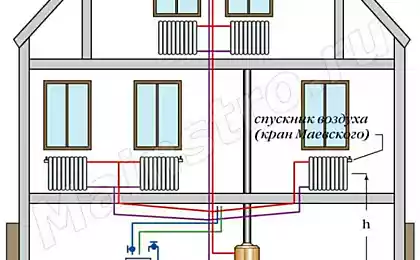

24.Nachalnaya stage strapping radiator. Each battery system, we will be connected via the bypass, ie if necessary zameny- each battery can be removed without emptying the whole heating system.

25.Polnostyu "tied with" first radiator.Sobiraem remaining two.

26.Trassu decided to lay on the sub-floor, in the future with the coolant pipes are embedded in concrete and will be under final polom.S help paint the cord break through a straight line along the wall, and fasten every meter clip to fix the pipe.

27.Nachinaem sequentially from the furnace into a single unit to collect our system.

28.Gotovim mount to install the circulating pump.

29.Vot and the pump is connected, full of happiness left to him to bring electrician.

30.Sobrana and set the security group, which consists of the expansion tank to 8l., Pressure relief valve, pressure gauge and air vent.

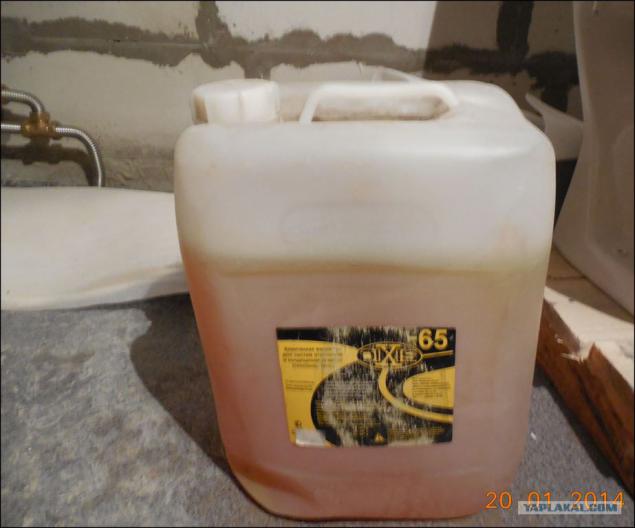

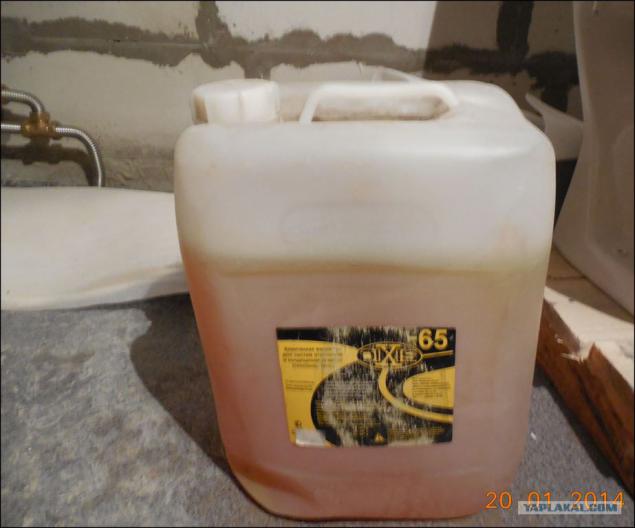

31.Ustanavlivaem crane for further filling of teplonositelem.Imenno through the valve will be filled with the entire system, the required pressure and pumped it through the valve can be, if necessary, drain the entire system.

32. In use as a coolant antifreeze DIXIS 65.Temperatura freeze concentrate Dixis up to -65S, when diluted with water - up to 30C. We will dilute the concentrate with water in a ratio of 1/1, so the system does not freeze even when the temperature is -30 ° C (in a building is not possible).

33.Pristupaem to fill the coolant system, use a submersible pump "Kid».

34.Dlya on / off the circulation pump in the heating system will install near the pump key switch.

35.Siney tape was no need to use black.

36.Vnutrennosti switch.

37.Vyklyuchatel assembly, left key and pritsepit.Nasos switch located next to the stove to the host does not forget to include a melting furnace nasos.Mozhno install automatic, but it is more expensive.

38.V this time the system is already filled with anti-freeze, to create the necessary pressure for leak testing system. We examine the entire assembled system for leaks.

39.Vse OK, nothing anywhere techet.Sistema mounted completely filled with coolant. You can melt furnace.

40.Vmesto use wood briquettes that heat about 1, 6 times higher than that of the well dried birch wood.

41.Temperatura oven oven slowly creeping up. 30-40 minutes of intense protopki reaches ok.200S.

42.Zakanchivali work in the dark, lit the fire in the stove, heat transfer fluid is heated with it and heat radiators otopleniya.Primerno half an hour of intense firing heat sinks have hot - do not you touch.

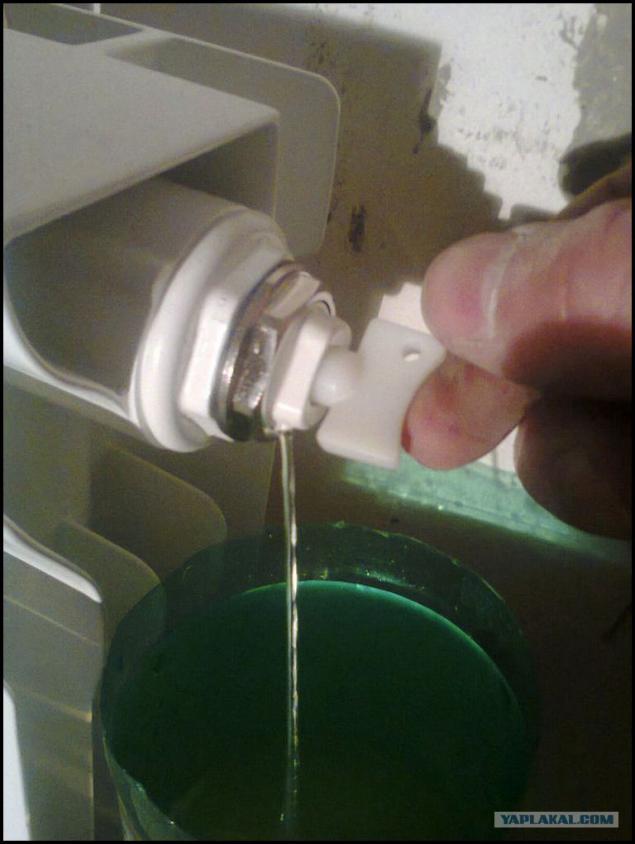

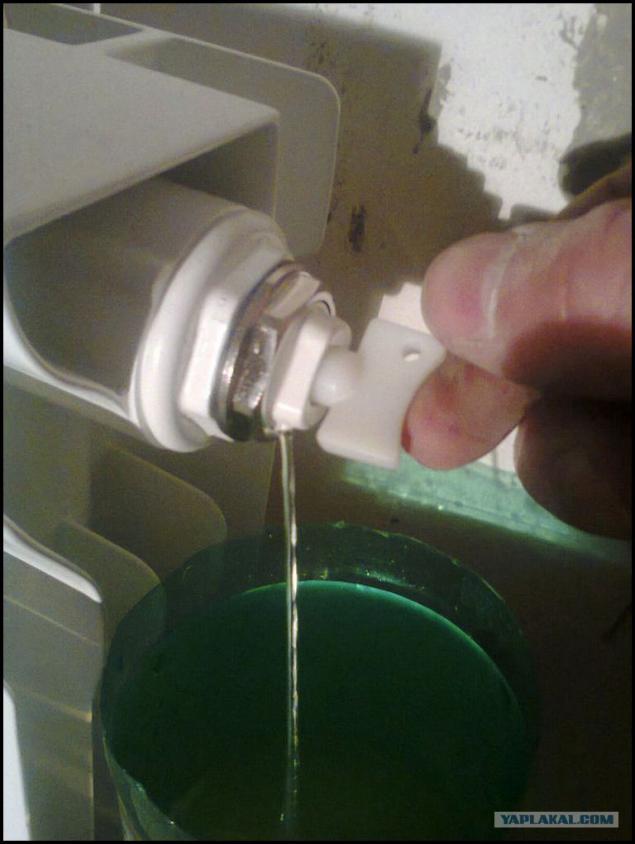

43.S a special key to the bleed screw of the release of the remaining air.

Posted in [mergetime] 1390658952 [/ mergetime]

That's all I wanted to say! You can evaluate, criticize arguments, to ask voprosy.Spasibo.

Source: http: //

2.Imeetsya oven (flue installed for a week ranshe- this will be a separate post) .This model furnace allows you to connect a maximum of 45 sections radiators, ie theoretically it was possible to make the system of two floors, but the budget was limited and it was decided at the first stage heat only the first floor.

3.Pech rear view. Here we see the two fitting: the lower - the entrance, top - out. This will connect our radiators. In total, the system will have 3 batteries - 2 pcs. 8 sections, and 1 pc. 6 sections. Obogreem these radiators 1 living room, bathroom and hallway.

4.Vyhody on the stove - 1 inch. For the sealing of threaded connections use UNIPAK together with flax sanitary.

5.Nakruchivaem transition 3/4 dyuyma.T.k.v system will use a circulating pump We do not need a large cross-section of water pipe - will drive the coolant pump and a pipe with a smaller secheniem.Dyuymovye pipe should be used in systems with natural circulation.

6. When the installation using a flexible corrugated pipe Kofulso stainless stali.V roll - 30 meters. The rest of the package - easy to use for storage of automobile wheels, so do not cut the cover and gently untie.

7A's pipe itself. corrugated pipe made of stainless steel is a modern material for pipeline installation of almost any purpose: heating systems, hot and cold water, drain and serve any zhidkostey.Ona steel combines strength and flexibility of rubber hose. Only the pipe by displacement Kofulso not afraid and does not change its diameter, such as rubber or plastic.

8.Perehodim the preparation of the site of attachment of radiators: mark up the holes with the expectation that the radiator appeared in the middle of the window and 15cm below the sill of the future.

9.Na this object wall of my foam-HITACHI easily coped worse when the walls betonnye- here already have to tinker with the hammer.

10. In the prepared hole anchor we exhaust spacer plastic nylon 6 NAT Sormat Sormat.

11.For embedding anchors using mallet STAYER PROFI 2052-90.Ona is a tool the size of 90 mm series PROFI, percussive element is made of rubber in black and has a cylindrical shape with flat sides and a metal handle.

12.Gotovo! And exactly in the intended place! Rare udacha.Povtoryaem 32 times.

13.Ustanavlivaem mount radiators.

14.Vse ready for the first radiator.

15.Proveryaem on urovnyu.V within tolerance ... so what could be there! - Perfect !!!

16.Teper proceed to the laying of track between batareyami.Nachnem with drilling sten.V arsenal could not find the right drill diameter and dliny.Prishlos out of the situation. First passes through the wall of a thin brown. The punch comes in.

17.A is now on both sides of the wall increase the hole to the desired diameter.

18.Prosovyvaem the resulting hole in the pipe.

19.Hotel a drink of water, it appears that while we worked hard, water has moved from liquid to solid and drink it in this form of the bottle neudobno.Poetomu continue to work.

20.Prodolzhaem pass through walls. This corner was littered with various nishtyak, so first had to move everything on the center of the room and free for a foothold.

21.Poka I practice the exercises with the hammer, a partner engaged in the preparation of radiators again using flax and Unipak cheat American, plugs and bleed screw.

22.Ne forget to seal all the threaded connections and the use of flax UNIPACK.

23.Trubu Kofulso cut using a special cutter or as an option - you can use the grinder.

24.Nachalnaya stage strapping radiator. Each battery system, we will be connected via the bypass, ie if necessary zameny- each battery can be removed without emptying the whole heating system.

25.Polnostyu "tied with" first radiator.Sobiraem remaining two.

26.Trassu decided to lay on the sub-floor, in the future with the coolant pipes are embedded in concrete and will be under final polom.S help paint the cord break through a straight line along the wall, and fasten every meter clip to fix the pipe.

27.Nachinaem sequentially from the furnace into a single unit to collect our system.

28.Gotovim mount to install the circulating pump.

29.Vot and the pump is connected, full of happiness left to him to bring electrician.

30.Sobrana and set the security group, which consists of the expansion tank to 8l., Pressure relief valve, pressure gauge and air vent.

31.Ustanavlivaem crane for further filling of teplonositelem.Imenno through the valve will be filled with the entire system, the required pressure and pumped it through the valve can be, if necessary, drain the entire system.

32. In use as a coolant antifreeze DIXIS 65.Temperatura freeze concentrate Dixis up to -65S, when diluted with water - up to 30C. We will dilute the concentrate with water in a ratio of 1/1, so the system does not freeze even when the temperature is -30 ° C (in a building is not possible).

33.Pristupaem to fill the coolant system, use a submersible pump "Kid».

34.Dlya on / off the circulation pump in the heating system will install near the pump key switch.

35.Siney tape was no need to use black.

36.Vnutrennosti switch.

37.Vyklyuchatel assembly, left key and pritsepit.Nasos switch located next to the stove to the host does not forget to include a melting furnace nasos.Mozhno install automatic, but it is more expensive.

38.V this time the system is already filled with anti-freeze, to create the necessary pressure for leak testing system. We examine the entire assembled system for leaks.

39.Vse OK, nothing anywhere techet.Sistema mounted completely filled with coolant. You can melt furnace.

40.Vmesto use wood briquettes that heat about 1, 6 times higher than that of the well dried birch wood.

41.Temperatura oven oven slowly creeping up. 30-40 minutes of intense protopki reaches ok.200S.

42.Zakanchivali work in the dark, lit the fire in the stove, heat transfer fluid is heated with it and heat radiators otopleniya.Primerno half an hour of intense firing heat sinks have hot - do not you touch.

43.S a special key to the bleed screw of the release of the remaining air.

Posted in [mergetime] 1390658952 [/ mergetime]

That's all I wanted to say! You can evaluate, criticize arguments, to ask voprosy.Spasibo.

Source: http: //