518

The truth about polymer-sand tile

Traditional tiles made of clay – roofing a classic, never goes out of fashion. However, she is very capricious in installation and operation, and the cost of such material is quite high. That is why appear the roof covering that simulates the appearance of clay tiles. However, their performance characteristics are far superior to the prototype. Among these materials thermoplasticity or, as it is called, polymer-sand tile.

The coating is a single or dvuhventsovye the rectangular plates with connecting strips. The average size of each sheet 400х310 mm. Color scheme is very diverse: from the traditional brick shades to vibrant green and blue tones. Fresh polymer-sand tile has a light Shine which after some time disappears and the coating becomes opaque.

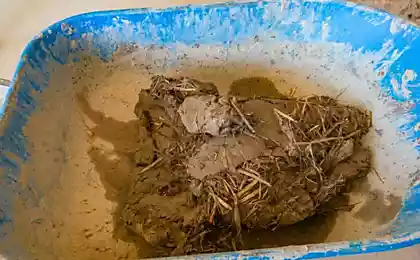

Properties of composite material are largely determined by the accuracy of the technology of its production. Here's how it works. First, preparing raw material, which is sand and polymers. The latter can be used after recycling. In this case, they need cleaned, sorted and crushed in a crusher. All components are thoroughly dried and then go to the shop.

In addition to the basic elements in the future of tile include various additives that improve its performance properties, and dyes. The dried components are mixed in the desired proportions and heated to the melting temperature. The melt is poured into molds, which come under the press. After cooling, taken out of the finished part.

Even small deviations from the production technology or the use of substandard raw materials cause a serious deterioration of product quality. For example, low-quality polymers are rapidly destroyed when exposed to UV radiation. If they became part of the shingles will last a very long. Unsorted the polymers in the melt will give a heterogeneous mass, which will delaminate during use. Therefore, you should not try to save on the purchase of polymer-sand tile. Cheap products of unknown origin will not last long and will not be able to show all the manufacturer's advantages. And they have high quality, certified a lot of material. First of all, it is a small weight that is a maximum of 25 kg per square meter. It is clear that this is not the lowest of all possible indicator, but in comparison with traditional clay tiles whose weight can reach 40 kg per square meter, the difference is obvious. Reinforcement of supporting structures of the composite, most likely, won't need. While under the cover of ceramics it is necessary. In addition, installation of polymer-sand tile because of the relatively small weight of sheets is simplified.

Composite material is resistant to various adverse effects, including aggressive chemicals. Moisture is not retained on the surface and does not penetrate. Mold and fungus on a roof do not develop. The low thermal conductivity of polymer-sand tile gives you the opportunity to save on additional insulation of the roofing.

The coating of the composite good muffles sounds, so tenants will enjoy peace even in the heavy rain or hail. In the production of tiles in its composition make supplements that give the material to frost. Therefore, at low temperatures, the coating does not crack and retains its basic properties. The manufacturer claims that the material can operate in temperatures ranging from +250 to -65 degrees Celsius. However, practice shows that at very low temperatures, composite tiles can lose their properties and deform.

Another significant advantage of the coating – the possibility of installation on roofs with a slope of 12 to 85°. Ceramics inclination laying impossible. However, the optimal slope of the roof under the composite – 35-55°. Such a range is specified in the recommendations of all manufacturers.

Over time the appearance of shingles does not change. The dye is added to the material before the melting and pressing, which prevents burnout. UV-resistant high-quality coating completely insensitive. In addition, polymer-sand tile is highly durable. It does not crumble and does not break during transport or an accidental fall, but if necessary, easy to cut with a grinder.

The disadvantages of composite coatings in addition to possible temperature deformations can be attributed to the rather complex installation. For its implementation we need a special skills, so a novice handyman, without experience of such work, he can hardly cope. Another disadvantage is the presence on the market of a large number of fakes that are only superficially similar to the certified material.

Polymeric roof tiles – a relatively new roofing material, is rapidly gaining popularity among developers. This is due to good performance and attractive appearance. It is very important to purchase certified coverage from a trustworthy manufacturer. The only way to get a quality material which during the operation will show all its declared properties. published

Source: www.stroitelstvo365.ru/vsyo-o-krovle/vsya-pravda-o-polimernoj-cherepitse

The coating is a single or dvuhventsovye the rectangular plates with connecting strips. The average size of each sheet 400х310 mm. Color scheme is very diverse: from the traditional brick shades to vibrant green and blue tones. Fresh polymer-sand tile has a light Shine which after some time disappears and the coating becomes opaque.

Properties of composite material are largely determined by the accuracy of the technology of its production. Here's how it works. First, preparing raw material, which is sand and polymers. The latter can be used after recycling. In this case, they need cleaned, sorted and crushed in a crusher. All components are thoroughly dried and then go to the shop.

In addition to the basic elements in the future of tile include various additives that improve its performance properties, and dyes. The dried components are mixed in the desired proportions and heated to the melting temperature. The melt is poured into molds, which come under the press. After cooling, taken out of the finished part.

Even small deviations from the production technology or the use of substandard raw materials cause a serious deterioration of product quality. For example, low-quality polymers are rapidly destroyed when exposed to UV radiation. If they became part of the shingles will last a very long. Unsorted the polymers in the melt will give a heterogeneous mass, which will delaminate during use. Therefore, you should not try to save on the purchase of polymer-sand tile. Cheap products of unknown origin will not last long and will not be able to show all the manufacturer's advantages. And they have high quality, certified a lot of material. First of all, it is a small weight that is a maximum of 25 kg per square meter. It is clear that this is not the lowest of all possible indicator, but in comparison with traditional clay tiles whose weight can reach 40 kg per square meter, the difference is obvious. Reinforcement of supporting structures of the composite, most likely, won't need. While under the cover of ceramics it is necessary. In addition, installation of polymer-sand tile because of the relatively small weight of sheets is simplified.

Composite material is resistant to various adverse effects, including aggressive chemicals. Moisture is not retained on the surface and does not penetrate. Mold and fungus on a roof do not develop. The low thermal conductivity of polymer-sand tile gives you the opportunity to save on additional insulation of the roofing.

The coating of the composite good muffles sounds, so tenants will enjoy peace even in the heavy rain or hail. In the production of tiles in its composition make supplements that give the material to frost. Therefore, at low temperatures, the coating does not crack and retains its basic properties. The manufacturer claims that the material can operate in temperatures ranging from +250 to -65 degrees Celsius. However, practice shows that at very low temperatures, composite tiles can lose their properties and deform.

Another significant advantage of the coating – the possibility of installation on roofs with a slope of 12 to 85°. Ceramics inclination laying impossible. However, the optimal slope of the roof under the composite – 35-55°. Such a range is specified in the recommendations of all manufacturers.

Over time the appearance of shingles does not change. The dye is added to the material before the melting and pressing, which prevents burnout. UV-resistant high-quality coating completely insensitive. In addition, polymer-sand tile is highly durable. It does not crumble and does not break during transport or an accidental fall, but if necessary, easy to cut with a grinder.

The disadvantages of composite coatings in addition to possible temperature deformations can be attributed to the rather complex installation. For its implementation we need a special skills, so a novice handyman, without experience of such work, he can hardly cope. Another disadvantage is the presence on the market of a large number of fakes that are only superficially similar to the certified material.

Polymeric roof tiles – a relatively new roofing material, is rapidly gaining popularity among developers. This is due to good performance and attractive appearance. It is very important to purchase certified coverage from a trustworthy manufacturer. The only way to get a quality material which during the operation will show all its declared properties. published

Source: www.stroitelstvo365.ru/vsyo-o-krovle/vsya-pravda-o-polimernoj-cherepitse

How to successfully build a career

Thermal imaging can be in the service of the Builder and the homeowner