564

Asphalt, plastic,

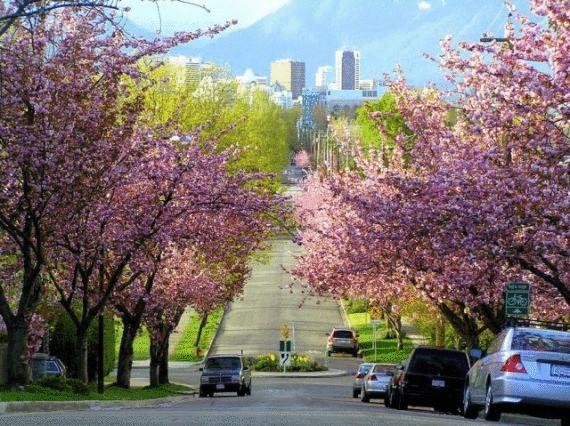

Local authorities have set an ambitious goal — by 2020 to transform Vancouver into the greenest city in the world (or rather, to add final touches). Under the new philosophy today, a project for the creation of pavements of asphalt (80%) with the addition of recycled plastics (20%). Hybrid asphalt will retain the familiar dark gray color and rough texture.

The innovation process developed by the company "Green Mantra" from Toronto, and its implementation has engaged the firm of "Green Roads". This idea has many advantages, starting with the possibility of recycling plastic benefit the environment and the economy. Plastic bottles, packages from-under milk and disposable cups – it's not just garbage, to be rid of is a valuable raw material for the manufacture of fabrics, containers, household items, and now building material for streets.

The plastic became part of the asphalt, it is melted to a paste and mixed with other components. The result has been to reduce the temperature of production of ready to use pavement from 160 to 120, which allows to save energy. At the same time in the atmosphere of 300 tons per year less of greenhouse gases and 30% less volatile organic compounds (VOCS) compared to traditional road construction works. An additional advantage is the possibility to lay new asphalt even in cold weather.

Plastic in asphalt will make the coating much stronger and will greatly prolong its service life. But even when over time, the pavement will begin to appear cracks, repair will be much easier than in the case of conventional asphalt. The latter has first warmed up, then crush, mix with reducing components and re-compacted. Hybrid coating will be enough to get very hot and reallocate – no more difficult than children's games with clay!

"We worked on this project for over a year to find the best way to use plastic waste in roads, as well as to ensure that it is safe," says chief engineer and Manager of the "Green Roads" Peter Judd (Peter Judd). – "To test on small sections of the road we started back in July, and 15 Nov changed the scale of the experiments and "saastalstrasse" the whole street. However, production of hybrid material 3% percent more expensive, it's a no brainer that the cost kompensiruet as a benefit of nature and the vast prospects for the future."

Peter Judd dispel doubts of skeptics that the use of plastic in asphalt is potentially dangerous. Plastic trash humanity will have to recycle anyway, so why not with the maximum benefit for motorists? The statement that it is not necessary to further increase the toxicity of the roads, where are the asphalt and oil, the city engineer says simply: "Plastic comes from oil, and asphalt is the same hydrocarbon. I don't think mixing them is more dangerous than to use only asphalt".

By the way, in Phoenix, Arizona, asphalt mixed with recycled rubber tires, not only for the liberation of the city dumps. Residents are satisfied: during rain the road surface is less slippery and therefore safe for drivers, and when the rain stops, the roads dry out very quickly. In addition, significantly reduced the traffic noise. To build a totally new road surface and thinking in Washington: research engineer Haifang Level (Haifang Wen) is working to replace the asphalt thickened waste vegetable oil.

Source: /users/104

The innovation process developed by the company "Green Mantra" from Toronto, and its implementation has engaged the firm of "Green Roads". This idea has many advantages, starting with the possibility of recycling plastic benefit the environment and the economy. Plastic bottles, packages from-under milk and disposable cups – it's not just garbage, to be rid of is a valuable raw material for the manufacture of fabrics, containers, household items, and now building material for streets.

The plastic became part of the asphalt, it is melted to a paste and mixed with other components. The result has been to reduce the temperature of production of ready to use pavement from 160 to 120, which allows to save energy. At the same time in the atmosphere of 300 tons per year less of greenhouse gases and 30% less volatile organic compounds (VOCS) compared to traditional road construction works. An additional advantage is the possibility to lay new asphalt even in cold weather.

Plastic in asphalt will make the coating much stronger and will greatly prolong its service life. But even when over time, the pavement will begin to appear cracks, repair will be much easier than in the case of conventional asphalt. The latter has first warmed up, then crush, mix with reducing components and re-compacted. Hybrid coating will be enough to get very hot and reallocate – no more difficult than children's games with clay!

"We worked on this project for over a year to find the best way to use plastic waste in roads, as well as to ensure that it is safe," says chief engineer and Manager of the "Green Roads" Peter Judd (Peter Judd). – "To test on small sections of the road we started back in July, and 15 Nov changed the scale of the experiments and "saastalstrasse" the whole street. However, production of hybrid material 3% percent more expensive, it's a no brainer that the cost kompensiruet as a benefit of nature and the vast prospects for the future."

Peter Judd dispel doubts of skeptics that the use of plastic in asphalt is potentially dangerous. Plastic trash humanity will have to recycle anyway, so why not with the maximum benefit for motorists? The statement that it is not necessary to further increase the toxicity of the roads, where are the asphalt and oil, the city engineer says simply: "Plastic comes from oil, and asphalt is the same hydrocarbon. I don't think mixing them is more dangerous than to use only asphalt".

By the way, in Phoenix, Arizona, asphalt mixed with recycled rubber tires, not only for the liberation of the city dumps. Residents are satisfied: during rain the road surface is less slippery and therefore safe for drivers, and when the rain stops, the roads dry out very quickly. In addition, significantly reduced the traffic noise. To build a totally new road surface and thinking in Washington: research engineer Haifang Level (Haifang Wen) is working to replace the asphalt thickened waste vegetable oil.

Source: /users/104