421

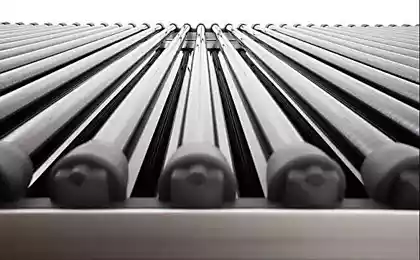

Solar modules come from Novocheboksarsk

At the company "Hevel" with participation of specialists of Japanese corporations Tokyo Electron Limited (main technology contractor) began a phased launch of the main systems of production line.

Currently fully assembled, configured, and functioning of all the sections of the final Assembly of solar modules — the so-called back-end. In particular, the configuration of the laser scribing, separating the solar modules into individual cells and provides them the serial connection in an electrical circuit. Specialists KUKA implemented and configured software for robots that sets the terminal box at the final stage of Assembly of the solar module.

At the same time experts TEL completed commissioning on the site front-end, which made the initial technological operations of a full production cycle. At the moment the tests systems KAI and TCO — key sections of the technological line, is intended for application micromorph silicon and conductive layers of zinc oxide. Also run and operate the automatic washing of the front and rear glass. Previously performed a complex of works on preparation of clean rooms class ISO 7 and ISO 8 that has been transferred to the fully functional mode.

The company has already signed agreements for the supply of the necessary for the production of solar modules of raw materials, such as glass, optical quality, technological gases etc.

At this stage, the engineers and technologists of the enterprise have to debug all processes and by July of the current year to reach the design parameters of the plant.

It is planned that by the end of the year the plant will produce not less than 200 thousand photovoltaic modules for the construction of solar power plants with installed capacity of 25 megawatts.

Source: greenevolution.ru

Currently fully assembled, configured, and functioning of all the sections of the final Assembly of solar modules — the so-called back-end. In particular, the configuration of the laser scribing, separating the solar modules into individual cells and provides them the serial connection in an electrical circuit. Specialists KUKA implemented and configured software for robots that sets the terminal box at the final stage of Assembly of the solar module.

At the same time experts TEL completed commissioning on the site front-end, which made the initial technological operations of a full production cycle. At the moment the tests systems KAI and TCO — key sections of the technological line, is intended for application micromorph silicon and conductive layers of zinc oxide. Also run and operate the automatic washing of the front and rear glass. Previously performed a complex of works on preparation of clean rooms class ISO 7 and ISO 8 that has been transferred to the fully functional mode.

The company has already signed agreements for the supply of the necessary for the production of solar modules of raw materials, such as glass, optical quality, technological gases etc.

At this stage, the engineers and technologists of the enterprise have to debug all processes and by July of the current year to reach the design parameters of the plant.

It is planned that by the end of the year the plant will produce not less than 200 thousand photovoltaic modules for the construction of solar power plants with installed capacity of 25 megawatts.

Source: greenevolution.ru

What is the conflict of General relativity and quantum mechanics

The end of an era of electronic books