In the same days of April 1970 was played probably the most dramatic story of everything that happened in the cosmos. Three astronauts who went to the Moon, found themselves in mortal danger and had to return home for three days, overcoming various difficulties encountered. This is a very beautiful story about how small changes in the specification can lead to big problems, coordinated work of hundreds of people in MCC mode Abraham about the courage and professionalism.

reason h4> As it happens regularly in complex technical systems and large projects, the cause of the accident was laid years before flight "Apollo 13" and the accident itself was formed from a complex chain of events, and the lack of any link led would lack the accident.

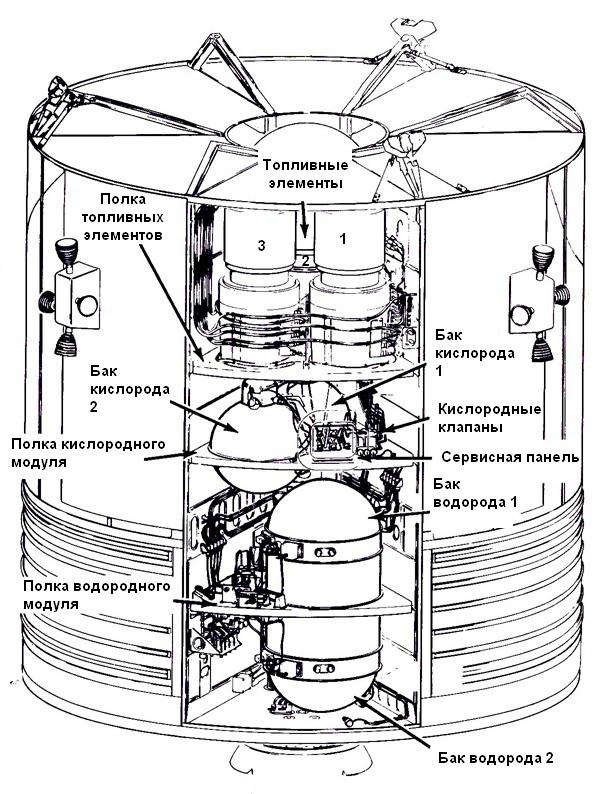

design h5> In order to understand what happened, you need to tell us about the structure of the service module "Apollo»:

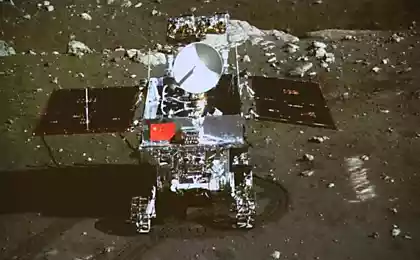

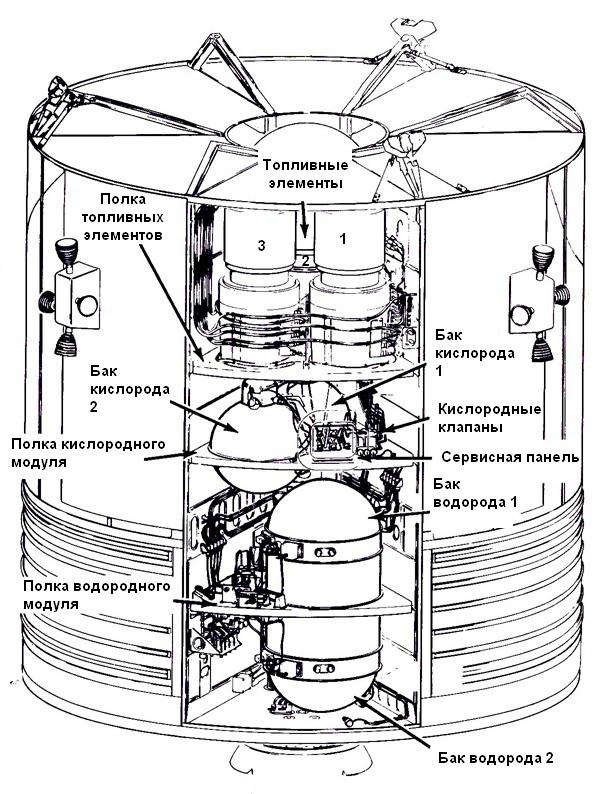

Energy subsystem service module "Apollo" consisted of two tanks of hydrogen, oxygen tanks and two of three fuel cells. Fuel cells, consuming hydrogen and oxygen to produce electricity and water that is consumed by the crew for drinking and cooling equipment. This was a very effective system better than solar panels, with the proviso that the flight will not be longer than 2-3 weeks.

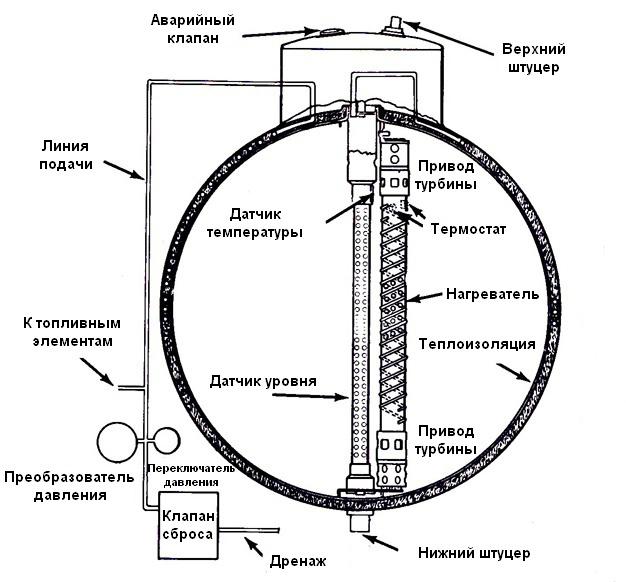

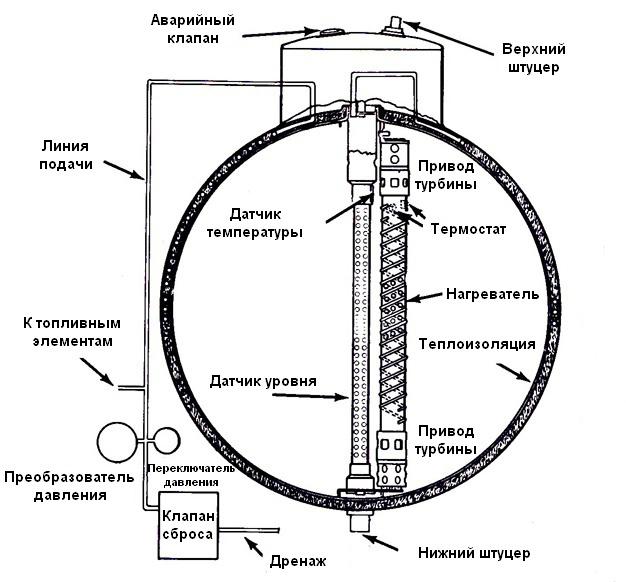

This - the oxygen tank service module "Apollo." He is so well insulated that can store liquid oxygen years. Liquid oxygen is stored therein in a state сверхкритической liquid , and therefore exhibits the properties of liquid and gas. As is well known, the expansion gas temperature is lowered. Thermal insulation is so good that cooled liquid oxygen would have lost Supercritical properties simply by expansion in the normal flow to the fuel cells. So we had to put a special heater to maintain the required temperature and pressure. In weightless liquid oxygen in a supercritical state has a bad habit to flake, liquid and gaseous layers, resulting in incorrect readings level sensor. So we had to put a special impeller for mixing oxygen and crew in a set of "work at home" added the procedure of mixing of oxygen in the tanks to Houston after her MCC could get accurate data on the amount of oxygen on board.

A small change in the specification h5> 1965. Before the flight "Apollo 13" five more years, until the first unmanned flight «AS-201" for another year, even the program "Gemini" only this year made its first manned flight. Actively working on the ship "Apollo". Due to the enormous scope of the work NASA contractors hire subcontractors for the manufacture of the necessary elements. Service module "Apollo" made «North American Aviation», as it did for tanks Subcontractor «Beech Aircraft». Since fuel cells were given 28 volts voltage in the specification of the tank indicated operating voltage 28 volts. However, in the process of developing the service module revealed that in preparation for the launch of "Apollo" will receive electricity from the generators ground launch complex, and they have a working voltage of 65 volts (quite a normal situation, when many qualified people doing a big project, no joke) . Therefore, the specification should be altered. Engineers «Beech Aircraft» Change Equipment oxygen tank, but forgot to change under the new strain of only one thing - the thermostat contacts. They are intended for disconnecting the heater circuit when needed. Quality control at all levels - «Beech Aircraft», «North American Aviation» and NASA did not notice this error.

Moving tanks h5> 1968. Tanks, which ended up on the "Apollo 13" is set in the service module, which will become part of the "Apollo 10". Since the tanks amended, after some time, it was decided to set to "Apollo 10" tanks newer version already installed and remove, upgrade and put on another service module. In the process of removing the tanks workers forgot to turn off one bolt, and winch, have already begun to raise the regiment with tanks, tanks stalled and dropped back into the rack. The drop height was ridiculous, 5 cm., But for space applications is a serious emergency. The incident documented, tested the tank, found him intact and sent on upgrades. Obviously, modernization was not associated with a serious dismantling of the tank (this is important for understanding the next phase). After upgrading tanks placed in service module "Apollo 13».

The same tank number two in the foreground, photographed after installation. I>

cocking h5> March 27, 1970, two weeks before the start of "Apollo 13". Produced the so-called training prelaunch countdown - complete simulation start with dressing ship working fluid transition to Flight atmosphere, in short, everything except the real team "Ignition". The simulation was successful with one exception - the tank number two refused to be emptied after the test. In the process of solving the problem, engineers suggested that the fall in 1968 was damaged bottom drain fitting. Theoretically, this is an emergency, it is necessary to transfer the start and change the tanks. On the other hand, the lower drain fitting is used only once - in the training prelaunch count. In flight, it is not needed, and you can fly with inoperative fitting. Therefore, to bleed oxygen suggested the use of a heater, gasification oxygen, which evaporates by gravity through the upper fitting. The decision agreed with the commander of the ship astronaut Jim Lovell. Jim signed the documents on the basis of the available data: the proposed solution is the best of invented, other fault is detected, the in-flight lower connection is not needed, and the change of the tanks will take forty-five hours apart to check for new tanks that will break schedule prelaunch and launch delay for a month.

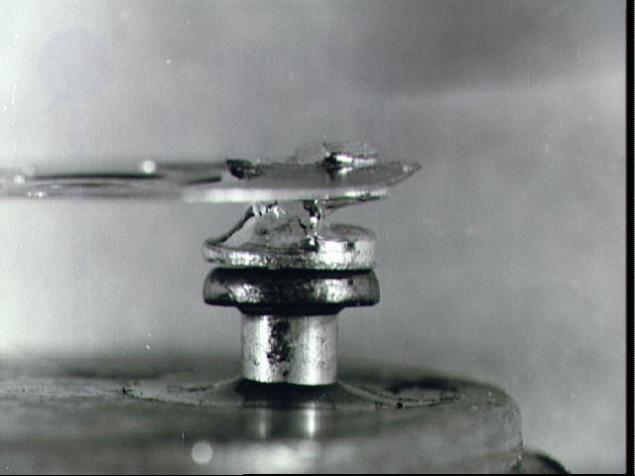

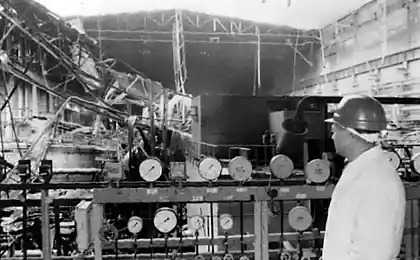

When you turn on the heater with the ground voltage 65 volt thermostat contacts, designed for 28 volts, is welded to the "on" position, the heater has lost the opportunity to turn off:

shutting contacts, photos natural experiment to reproduce the crash. I>

A temperature sensor inside the tank, made to measure the operating temperature near -207 degrees, the upper limit of the measurements was 27 degrees. Engineer supervising the work could only get two options - "Heater On" and "temperature is above 27 degrees." In reality, always-on heater quickly vaporized oxygen and continuing to work in an empty tank, heated up to 540 degrees. Somewhere in the vast complex of buildings was the launch pad recorder, DC fixing heater cycles instead of "on-off", but no one looked at his belt before the accident. Rascal to 540 degrees heater melted Teflon insulation and wires become a detonator.

Freelance heating was impossible to fix itself - the tank was well insulated, so the fire in the service module could not be, and contingency temperature lasted until prelaunch refueling when a new liquid oxygen cooled the interior of the tank.

Actors h4>

The crew of "Apollo 13» h5>

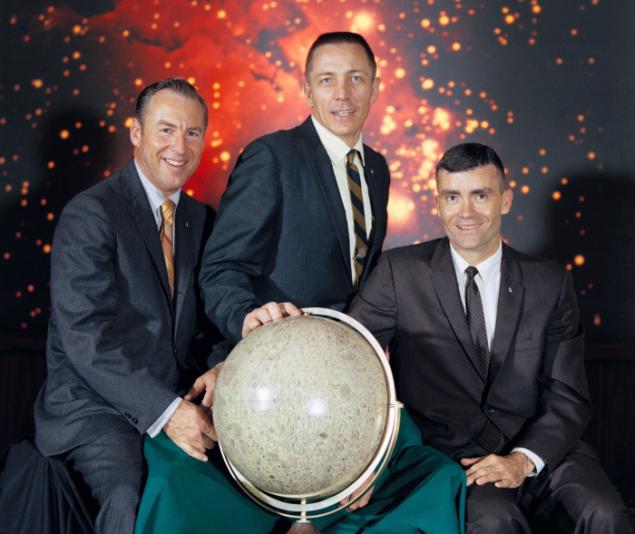

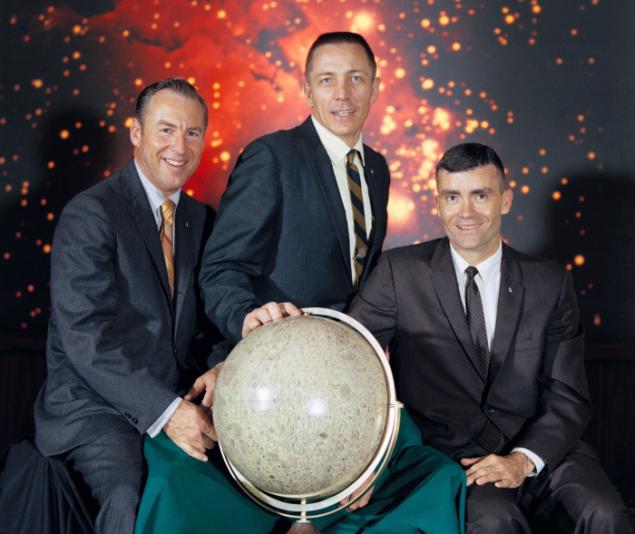

From left to right: Lovell, Suaygert, Hayes. Photographed in a hurry because of the replacement crew. I>

Jim Lovell - Commander, a veteran of the space program, made two flight to "Gemini" and circled the moon on the "Apollo-8».

John Suaygert - command module pilot. The first flight into space, was a backup crew, transferred to the prime crew for a few days before the flight because of the fact that the main astronaut crew - Ken Mattingly contact with astronaut Charles Duke, rubella, and did not have immunity to rubella. The first bachelor among astronauts.

Fred Hayes - lunar module pilot. The first flight into space.

MCC Houston h5>

Gene Kranz - the head of "the white team," the main flight change (a total of four shifts), and leading executives fly.

«White team." The mission is unknown. I>

Crash h4> 55 hours 54 minutes flight. The regular inclusion of mixing tanks (it includes regularly, more than once a day) caused a short circuit in the tank number two. Teflon insulation on fire:

Burning Teflon oxygen, photography natural experiment to reproduce the crash. I>

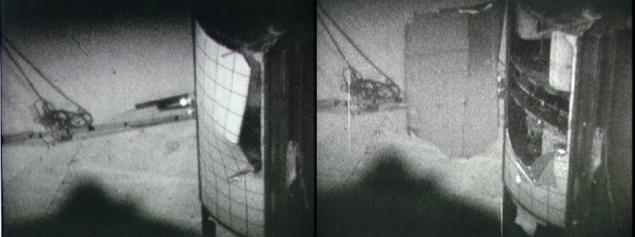

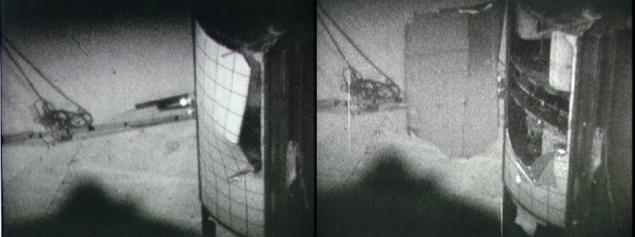

Teflon burning in oxygen caused a rapid heating of the tank and the pressure increase, exceeding the limits of the strength of the tank. Blew off the top cover of the tank:

The collapse of the cover photograph natural experiment to reproduce the crash. I>

The sharp increase in pressure blew off sheet cladding section service module:

The collapse of the panel, picture of natural experiment to reproduce the crash. I>

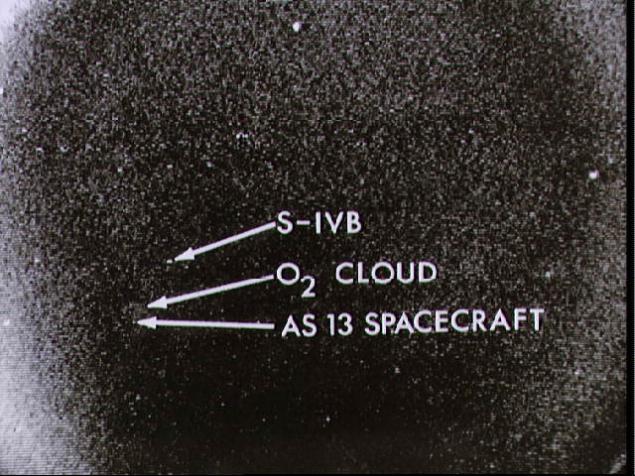

In addition, the shake-up of the disruption caused unintended tank cover closing valves of fuel cells 1 and 3, leading to the shutdown of three minutes, and led to the leaking pipeline oxygen tank number one. After 130 minutes, the pressure in the oxygen tank number one dropped to zero - the command module lost water and energy. From the Earth, he was at a distance of 320,000 kilometers.

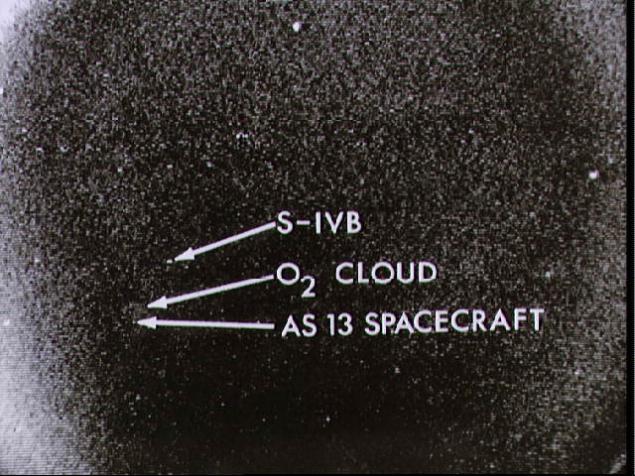

Photo from ground-based telescope. I>

«Houston, we've had a problem here» h4>

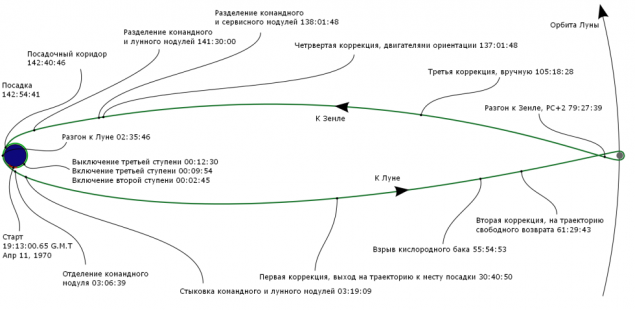

The scheme of flight. I>

Yes, the phrase meme sounded in the original that way: «Houston, we've had a problem here». Astronauts and MCC, of course, did not have full knowledge of the situation told in the previous paragraph, so the first few minutes, people have tried to understand what had happened. In any cosmic accident, you must first establish a real problem or failure of sensors / telemetry. First crew to restart the computer, reported the indicators that connect fuel cells to different supply rails to understand what is happening. But fifteen minutes later Jim Lovell said that is leaking some gas from the service module - the problem was clearly very serious, and it is far from ended.

At this time, the MCC has sounded another catch phrase - "Guys, let's solve the problem. Let's not worsen the situation guesses. »

The initial task was to attempt to rescue the remaining oxygen in the tank number one. Despite all attempts, the leak could not be isolated, pressure continued to fall. The only possibility was the inclusion of the lunar module, which became a lifeboat. Work had to spend very quickly, while shutting down the command module and lunar including. The inclusion of the lunar module for instructions took about three hours. Leakage rate increases, and when it became clear that the fuel cell will last less than fifteen minutes, we had to change the procedure for inclusion on the go. A separate problem is the navigation. It was necessary to rewrite the data gyro-stabilized platform command module, a recount (corners docking command and lunar module were not exactly 180 degrees) and enter the data to gyrostabilized platform lunar module. Complicated procedure was successfully performed. The command module is disabled, the lunar module took control.

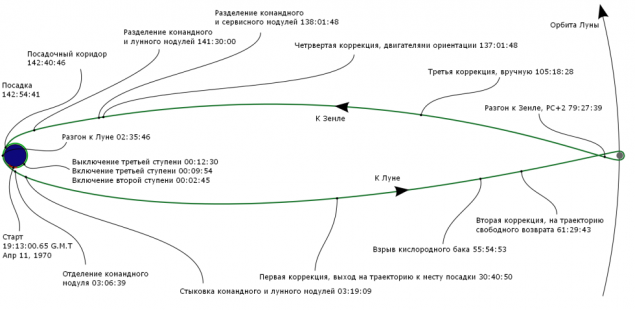

Tough choices and the first trajectory correction h4> The next challenge was the choice of mode of return. All the "Apollo" flew along this trajectory (eg free return trajectory), which allowed flyby of the moon and a normal landing on Earth. Because of this, all landing "Apollo" was near the lunar equator. At the same time, there were an emergency return mode when a sufficiently long impulse engines ship returned to Earth without a flyby of the moon:

After quite a busy meeting (there sounded another catch phrase - «The failure - is an invalid option» abbr>), we decided to stay on the trajectory of free return. Arguments:

Option with the shooting of the lunar module to reduce the mass, which would need to slow down, become impossible. Option to use the lunar module engine until enough fuel, did not give an appreciable prize in time. A reset service module could break the thermal regime of the heat shield on the bottom of the command module. Damage to the heat shield made landing impossible. supplies (water, electricity), according to the calculations enough to return freely. The main engine service module may have been damaged, and its use was a greater risk . The ship was already close to the Moon and returning the emergency maneuvers were becoming less profitable However, "Apollo 13" has already come down with a free return trajectory. A slight deviation was needed for planting in the selected area. So we had to make a correction of the lunar module landing engine, turning it on for 30 seconds. Another problem was to navigate. Pieces of insulation, taken in the destruction of the oxygen tank, abundant scattered around the ship, becoming false stars. So we had to use the sun to check the accuracy of orientation. Fortunately, the data has been transferred correctly and gyro stabilized platform is working properly maintain accurate navigation, and correction was successful.

Maneuver PC + 2 h4> The trajectory of free return and require little maneuver. He performed two hours after perilune (periapsis around the moon), so called simply "perilune +2» (PC + 2). Thanks to him, the landing point has shifted from the Indian to the Pacific Ocean, where the main ships were nominally provide landing and landing time has moved forward by 10 hours. Landing engine of the lunar module, designed for one switch before planting, included for the second time, and he worked for 4 minutes 24 seconds.

austerity h4> The lunar module running on battery power, rather than fuel cells. Therefore, on the one hand, the oxygen was in abundance, because it was used for filling the lunar module after reaching the surface of the moon. On the other hand, electricity and water shortages were ill. The lunar module was designed to operate for two people and a half days, but now he had to provide three people for four days. Therefore, after the release of the ship due to the disc of the moon has taken all possible measures to save electricity and water. Water for human consumption and spent on cooling equipment. Therefore, in the lunar module was turned off everything that is possible, and the people had to endure thirst. When preparing to sleep in the command module of habit drew the curtains on the windows, he quickly cooled down and never warmed up to the landing. In the lunar module, the situation was a little better, but there was so cold that the water dew settled on the walls and panels.

To thrust a square peg into a round hole h4> In English, there is an idiom - "a square peg in a round hole» - «square peg in a round hole». It denotes a person is not in place. And in flight "Apollo 13" idiom has become a reality. Despite the abundance of oxygen for the crew brewing trouble breathing. The fact that the carbon dioxide exhaled by something must absorb. More than 15% of carbon dioxide in the inspired air leads to impaired vision, then consciousness, and, ultimately, death. In the lunar module were round canisters of lithium hydroxide, which absorb carbon dioxide. But they are not enough. In the command module was enough lithium hydroxide canisters, but they were square:

Photos from the film "Apollo 13", but the meaning is transmitted very true. I>

Therefore, the problem arose quickly create a way to shove a square peg into a round hole. Special group, taking the same materials as those who were on the "Apollo 13", quickly assembled adapter and instructions on how to assemble. The idea was simple enough - the canister was placed in a package that fed air from the air pump system. Package taken from the package of flight suits, hose - from suits, sealed it with tape, put the lid bent Flight Plan as spacers for uniform air distribution and the correct hole in the canister closed toe and closed up the same tape.

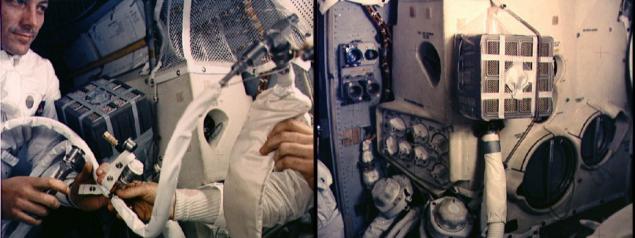

The assembly adapter and a working device. Blowing something vaguely mother ... i>

Instructions passed to the "Apollo 13" and in space have collected the same adapter. The problem of carbon dioxide has been resolved.

Critical procedure h4> Along all these cases was extremely hard work to create a start-up procedure of the command module. Without the inclusion of the command module landing was impossible. A switch was complicated by the fact that its batteries were already partly discharged, and the procedure is completely turn off the command module not only has been developed in advance of her wonder and in the simulator is not checked.