167

Biofuels from brewing waste

An unusual type of fuel was invented by Novosibirsk scientists from the Institute of Catalysis named after G. K. Boreskov SB RAS.

“One of the activities of our laboratory is the production of biofuels from microalgae. They are suitable for these purposes, because they grow rapidly, are widely distributed in nature, besides they store a large amount of lipids, which can then be processed into valuable chemicals, for example, into biodiesel, says Alexander Piligayev, a junior researcher at the IK SB RAS.

Usually, the life cycle of microalgae, during which they manage to grow and gain biomass, is about two weeks. One way to grow this crop is through wastewater from the food industry. The drains of breweries belong to the fifth (lowest) hazard class, as they contain a large amount of organic component that microalgae are able to consume and process.

“It would be more efficient to have less organic waste. This is exactly what microalgae can handle, which are capable of carrying out the so-called “pre-processing”. That is, with the help of one technology, you can kill two birds with one stone – and reduce the load on urban sewage systems, and get biofuel, Piligayev explained.

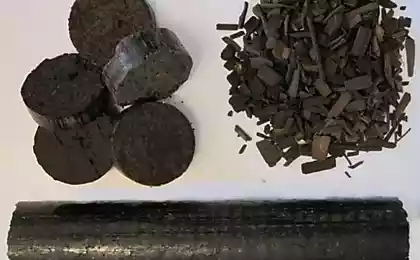

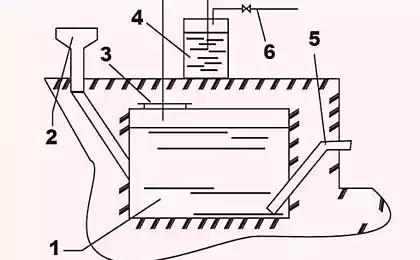

To date, in specially designed photobioreactors, scientists have already managed to obtain samples of microalgae biomass, as well as conduct experiments on their processing. The result is experimental samples of biofuel. Further research is underway to increase the productivity of lipids and optimize the processing of the obtained raw materials.

The problem is that if we now create such technology and implement it in practice, then the output fuel will be 5-6 times more expensive than traditional oil. Whether this direction will receive further development will depend on how much scientists will be able to reduce the cost of ways to cultivate algae, extract oil from them, and biofuel from it.

Source: greenevolution.ru

“One of the activities of our laboratory is the production of biofuels from microalgae. They are suitable for these purposes, because they grow rapidly, are widely distributed in nature, besides they store a large amount of lipids, which can then be processed into valuable chemicals, for example, into biodiesel, says Alexander Piligayev, a junior researcher at the IK SB RAS.

Usually, the life cycle of microalgae, during which they manage to grow and gain biomass, is about two weeks. One way to grow this crop is through wastewater from the food industry. The drains of breweries belong to the fifth (lowest) hazard class, as they contain a large amount of organic component that microalgae are able to consume and process.

“It would be more efficient to have less organic waste. This is exactly what microalgae can handle, which are capable of carrying out the so-called “pre-processing”. That is, with the help of one technology, you can kill two birds with one stone – and reduce the load on urban sewage systems, and get biofuel, Piligayev explained.

To date, in specially designed photobioreactors, scientists have already managed to obtain samples of microalgae biomass, as well as conduct experiments on their processing. The result is experimental samples of biofuel. Further research is underway to increase the productivity of lipids and optimize the processing of the obtained raw materials.

The problem is that if we now create such technology and implement it in practice, then the output fuel will be 5-6 times more expensive than traditional oil. Whether this direction will receive further development will depend on how much scientists will be able to reduce the cost of ways to cultivate algae, extract oil from them, and biofuel from it.

Source: greenevolution.ru