705

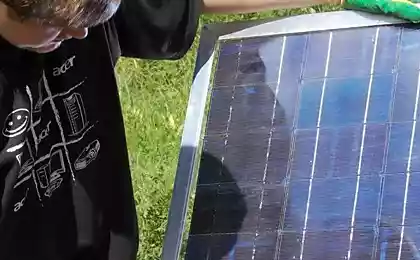

Printing solar cells on any material

Australian scientists specializing in solar energy, today, one step closer to creating a cheaper and faster way to print solar cells on plastic.

Senior researcher at CSIRO (national science Agency of Australia, one of the largest and most diverse research agencies in the world) Dr Fiona Scholes (Fiona Scholes) said that the technology is almost at the stage of commercialization and can be installed and used anywhere — from the laptops to recharge them to the supply of homes through the installation on the roof.

"Covers for tablets, mobile phones, bags for laptops – we want to serve not only for transport or protection devices, but also to generate power to charge electronics," says Dr. Scholes.

A consortium of Organic Solar cells (cooperation between scientific institutions and industry based in Victoria), which was behind the development of the project also involves scientists from CSIRO, the University of Melbourne and Monash University working on printing solar panels in 2007.

The team quickly showed results, creating a solar panel the size of a coin and oblivia its size to A3. Dr Scholes said the team used commercial printers that were re-engineered to work with solar ink.

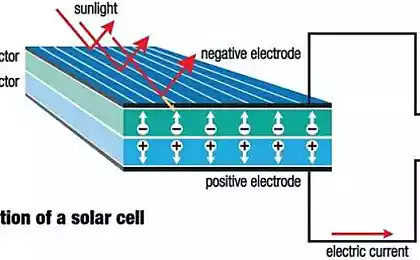

"It's very cheap. How it looks and works differs significantly from traditional silicon solar cells," she says.

"The solar panel can be made translucent, we can use it to tonirovania Windows." According to Dr. Scholes any plastic surface can be replaced by solar panels. This makes them ideal for power supply of the skyscraper, for example.

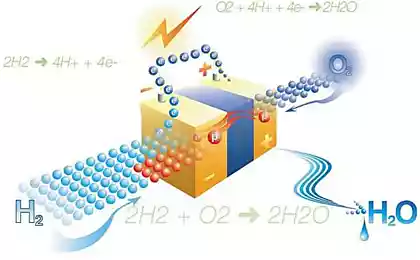

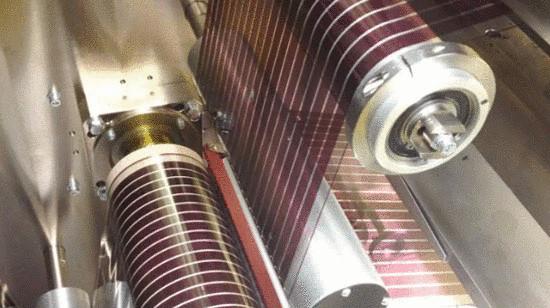

The team created a process that uses ink jet printing, reverse gravure printing and thin film deposition, along with silkscreen printing. Using semiconducting inks, researchers printed solar cells directly on a flexible, thick sheet of paper, a plastic PET substrate – the material that makes up bottles for mineral water and soda. Cells can also be printed in steel or translucent material to cover the Windows and cladding of buildings. Print speed at this time exceeded 10 meters per second, producing a finished solar cell every 2 seconds.

"We print solar panels on plastic in much the same way as print our plastic banknotes, credit cards," explains Scholes.

"Connect a solar panel is as simple as connecting the battery".

While the main drawback of this technology is that the printed solar panel only works at 10% efficiency silicon cells. However, the team expects to reduce the gap by improving solar inks, so that they were able to generate more electricity. The initial lifespan of the printed solar panels was only six months, but the team is working to increase this period to 10 years.

Dr. Scholes describes the difference between printed solar silicon: "It would be great if we were able to achieve similar power delivery at significantly reduced prices. Silicon falls in price, but think how cheap the plastic. Ink has a small cost, so that a raw materials cost-effectively. This is a big step forward, because you will be able to place these solar elements wherever we want. Also the applicability of these elements is much better than silicon – it works well in cloudy weather".

While the team can't produce a commercial product on their own, a number of companies have already volunteered to discuss the fabrication of solar cells. Although the printer that uses the team, worth about $ 200,000, the economies of scale of industrial production is expected to make solar cells more affordable.

Source: facepla.net

The most beautiful solar farm on the Planet

Facebook, Twitter and Google: the mechanics of disconnecting