3929

How is the birth of a hamburger

On the outskirts of Moscow, Solntsevo lives and works "McComplex" - a large plant was built 18 years ago, where enjoys uninterrupted production buns, hamburger patties and well known to every visitor "McDonald's". In addition to production, "McComplex" also serves as a distribution center, supplying everything you need - from semi-finished products to plastic straws and napkins - hundreds of food outlets.

In addition, there are special laboratories in which specialists achieve perfect dusting sesame buns, uncompromising density milkshakes and perfect juicy beef burgers. Below - the story of how we managed to get the camera to the factory, to peep process of birth hamburgers and meet with special instruments for calibration rolls.

A two-storey complex covers an area of about ten and a half thousand square meters, so it does not fit in the wide-angle. The picture shows the main entrance to the central "McComplex." Before entering three flags fluttering - one Russian and two corporate.

Left and right scurry hefty trucks approaching the complex and leaving him. Some are brought here ready meal, flour, meat, vegetables, sauces, branded clothing, tubes, liquid soap, etc. Other - carry about all this in restaurants or sent abroad (manufactured here pies are eaten not only in the capital and its environs, but also pleasing to the inhabitants of the countries of Eastern Europe).

A few more words about nutrition. The first question that I asked the employee "McComplex": what the food in the dining room? It was found that the products of its own production (cheeseburgers, etc.) are fed once a week; other days - that can be seen in all the other diners - soup, potatoes, juice and so on.

For example, on someone's tray "Filet-o-Fish" live well with soup and black bread.

So look from above warehouses. It houses everything that does not require low temperatures (eg, plastic spoons for stirring coffee cold storage temperature is required). There are "cold" part of the warehouse (where dairy products are stored and all that) and freezer (where waiting in the wings frozen patties and other bad heat transferring products). Initially "McComplex" serves first and only open at that time in Russia restaurant - in Moscow's Pushkin Square; Today it provides everything you need about 130 restaurants.

The picture shows the buns on the conveyor. In the hour produced 15,500 rolls. We'll come back to them.

When the dough configure themselves allotted time, it is loaded into a special machine. Then fill the dispenser equal portions test heat-resistant trays, which are to go into the oven.

Workshop for production of biscuits. In the foreground - a bath with fresh dough.

The next workshop - production of fillings for pies. Pictured: vat in which the cooked apples with cinnamon. When filling dovaritsya, it goes through the tube into the next room, where she will push into patties.

Then these segments is wound on a wooden stick. The resulting dough is loaded spool into the next car (which comes from a nearby shop Prepare the filling).

Pies are made very interesting. One machine rolls the dough into a broad band, which is cut into long stretches.

Almost finished patties on a conveyor belt. Every hour off the belt 13 000 pies. They left to cover the special glaze (that after deep-frying on the surface appeared nice crispy bubbles), frozen and distribution go where their fry and eat. By the way: a filling for pies - it is seasonal: soon there will produce cakes with strawberries, which at the time is ripe, and the closer to the fall - with raspberries.

The fate of the finished rolls is different: some to be done a long trip outside Moscow, pre-freeze, while others (pictured) immediately razvezut on capital supply points.

At the entrance to the shop equipped with devices for washing hands and shoes (work given special shoes, designed for water treatment).

Meat. Pictured: chilled beef domestic production.

Apparently, one of the most painful for the "McDonald's" moments - common in the general population view that branded burgers are made from almost anything, but not meat, so the meat during the tour showing very carefully. No less carefully demonstrates that in the manufacturing process is not added to the meat or soy, no toilet paper or anything else: each finished a hamburger - a wholly-owned beef (NB: all beef patties are made, which are equipped with hamburgers, cheeseburgers, Big Mac and so on; pork is used only for pork cutlets offered at breakfast).

From stuffing a bit more complicated. The fact is that to make mincemeat, compliance with corporate standards "McDonald's", entirely of domestic beef is not possible at all desire. Our Cows - they say, is too slim and lean. Not enough fat in general. Therefore, to the hamburger will not get too dry, cooled to domestic beef, ground into a meat grinder, add frozen Brazilian, grinds to another. The resulting meat cocktail already meets all brand standards.

Stuffing is loaded into the machine, which he sculpts the same neat patties.

Svezhesleplennye burgers crawl into the belly of a large refrigerator compartment.

After two and a half minutes the same burgers crawl out of the refrigerator at the other end of the shop - completely frozen - and folded in piles.

Ready frozen patties are weighed, packed in cardboard boxes and sent to the refrigerator for storage. An hour here is made about a half tons of hamburgers.

For tourists (and there are often guided tours) are provided disposable shoe covers. For sanitation fit very thoroughly: before every great tour hairnets, a white coat and a form to fill in which, inter alia, there is an item that does not get sick with typhus, and you did not communicate with similar whether patients over the past three weeks. And while walking on a range of employee acting as a guide, closely follows you to the right frequency to wash their hands, they did not climb in the minced meat and do not forget to wear shoe covers.

Pictured: Production Laboratory (near work still chemical and microbiological laboratory, but there outsiders are not allowed).

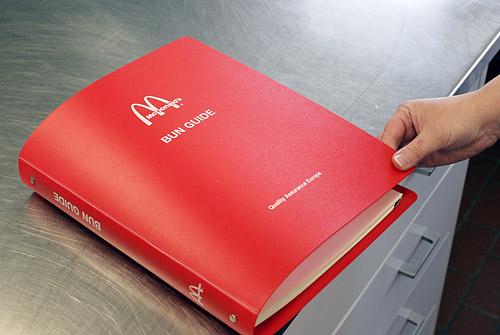

This is a book with the corporate guideline on buns. It contains detailed information about what the proper bun is different from wrong.

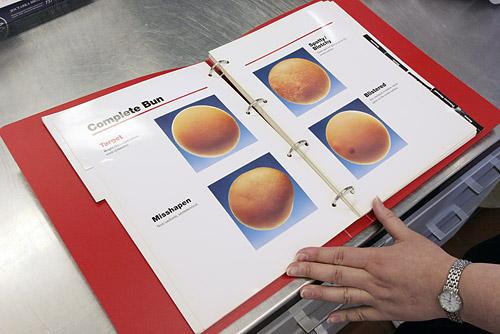

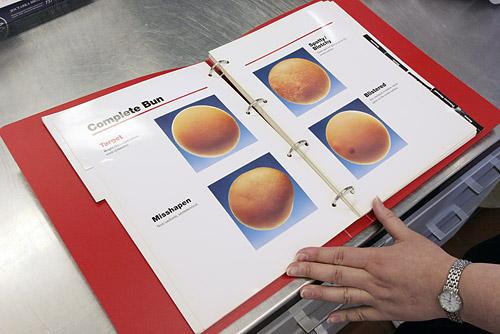

In the upper left corner - Photo correct ideal surface rolls, to strive. On the other three pictures show various defects. Similarly, on other pages clearly understand other parameters rolls: dusting sesame ("correct dusting", "too much sesame", "too little sesame", "uneven dusting"), cutting, shape, color, structure, size, absence of pits and so on. Well, that is a statement that on the way to the consumer hamburger takes about hundreds of tests, it is true that if you take any object to measure its weight, color, shape, texture, microbiology, shaggy, roughness, splendor, humidity, elongation at break , elasticity, transparency, etc., and even repeat the assessment several times - at the entrance of raw materials in the manufacturing process and the output - you probably will not lower.

There assess the quality of the finished product from each batch.

In the laboratory, found exactly the same equipment as in all restaurants, "McDonald's". Therefore, it suffices to take the neighborhood made a standard bun, place it in a standard toaster (pre-programmed for standard frying time rolls) and to assess whether the result meets the high standards of the company. In the same way everything else is tested (from vegetables to cocktails), but we'll see how we study the buns.

For comparison, the left and center - defective rolls, right - right, high-quality bun.

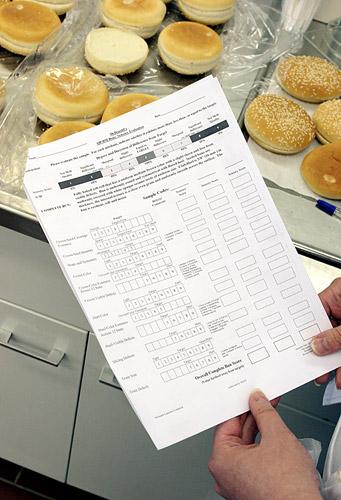

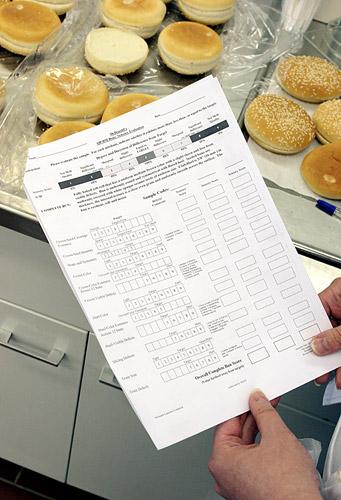

Results of the study rolls (each parameter is given a separate evaluation) fit into a questionnaire. If bun curves obtained improperly sliced, sprinkled with sesame seeds uneven, too pale, and pitted, then the lot is rejected. If bun fit into the established standards, the party passed.

Ideal for the bun "Big Mac».

This photo shows a special cardboard instrument for assessing the correctness of size and evenness of cutting buns for hamburgers / cheeseburgers (top notch), "Big Mac" (left) and "Royal" (bottom). "We need to - say - beg you this device to go with him to the nearest" McDonald's "and meticulously measure rolls directly on the counter." "And this device, - answer me - and so every restaurant there: they also conduct tests and discarded if necessary».

The tour ended and we went back into the hall "McComplex", where a commemorative marble tablet Soviet hammer and sickle is adjacent to the Canadian Maple Leaf.

via nl

In addition, there are special laboratories in which specialists achieve perfect dusting sesame buns, uncompromising density milkshakes and perfect juicy beef burgers. Below - the story of how we managed to get the camera to the factory, to peep process of birth hamburgers and meet with special instruments for calibration rolls.

A two-storey complex covers an area of about ten and a half thousand square meters, so it does not fit in the wide-angle. The picture shows the main entrance to the central "McComplex." Before entering three flags fluttering - one Russian and two corporate.

Left and right scurry hefty trucks approaching the complex and leaving him. Some are brought here ready meal, flour, meat, vegetables, sauces, branded clothing, tubes, liquid soap, etc. Other - carry about all this in restaurants or sent abroad (manufactured here pies are eaten not only in the capital and its environs, but also pleasing to the inhabitants of the countries of Eastern Europe).

A few more words about nutrition. The first question that I asked the employee "McComplex": what the food in the dining room? It was found that the products of its own production (cheeseburgers, etc.) are fed once a week; other days - that can be seen in all the other diners - soup, potatoes, juice and so on.

For example, on someone's tray "Filet-o-Fish" live well with soup and black bread.

So look from above warehouses. It houses everything that does not require low temperatures (eg, plastic spoons for stirring coffee cold storage temperature is required). There are "cold" part of the warehouse (where dairy products are stored and all that) and freezer (where waiting in the wings frozen patties and other bad heat transferring products). Initially "McComplex" serves first and only open at that time in Russia restaurant - in Moscow's Pushkin Square; Today it provides everything you need about 130 restaurants.

The picture shows the buns on the conveyor. In the hour produced 15,500 rolls. We'll come back to them.

When the dough configure themselves allotted time, it is loaded into a special machine. Then fill the dispenser equal portions test heat-resistant trays, which are to go into the oven.

Workshop for production of biscuits. In the foreground - a bath with fresh dough.

The next workshop - production of fillings for pies. Pictured: vat in which the cooked apples with cinnamon. When filling dovaritsya, it goes through the tube into the next room, where she will push into patties.

Then these segments is wound on a wooden stick. The resulting dough is loaded spool into the next car (which comes from a nearby shop Prepare the filling).

Pies are made very interesting. One machine rolls the dough into a broad band, which is cut into long stretches.

Almost finished patties on a conveyor belt. Every hour off the belt 13 000 pies. They left to cover the special glaze (that after deep-frying on the surface appeared nice crispy bubbles), frozen and distribution go where their fry and eat. By the way: a filling for pies - it is seasonal: soon there will produce cakes with strawberries, which at the time is ripe, and the closer to the fall - with raspberries.

The fate of the finished rolls is different: some to be done a long trip outside Moscow, pre-freeze, while others (pictured) immediately razvezut on capital supply points.

At the entrance to the shop equipped with devices for washing hands and shoes (work given special shoes, designed for water treatment).

Meat. Pictured: chilled beef domestic production.

Apparently, one of the most painful for the "McDonald's" moments - common in the general population view that branded burgers are made from almost anything, but not meat, so the meat during the tour showing very carefully. No less carefully demonstrates that in the manufacturing process is not added to the meat or soy, no toilet paper or anything else: each finished a hamburger - a wholly-owned beef (NB: all beef patties are made, which are equipped with hamburgers, cheeseburgers, Big Mac and so on; pork is used only for pork cutlets offered at breakfast).

From stuffing a bit more complicated. The fact is that to make mincemeat, compliance with corporate standards "McDonald's", entirely of domestic beef is not possible at all desire. Our Cows - they say, is too slim and lean. Not enough fat in general. Therefore, to the hamburger will not get too dry, cooled to domestic beef, ground into a meat grinder, add frozen Brazilian, grinds to another. The resulting meat cocktail already meets all brand standards.

Stuffing is loaded into the machine, which he sculpts the same neat patties.

Svezhesleplennye burgers crawl into the belly of a large refrigerator compartment.

After two and a half minutes the same burgers crawl out of the refrigerator at the other end of the shop - completely frozen - and folded in piles.

Ready frozen patties are weighed, packed in cardboard boxes and sent to the refrigerator for storage. An hour here is made about a half tons of hamburgers.

For tourists (and there are often guided tours) are provided disposable shoe covers. For sanitation fit very thoroughly: before every great tour hairnets, a white coat and a form to fill in which, inter alia, there is an item that does not get sick with typhus, and you did not communicate with similar whether patients over the past three weeks. And while walking on a range of employee acting as a guide, closely follows you to the right frequency to wash their hands, they did not climb in the minced meat and do not forget to wear shoe covers.

Pictured: Production Laboratory (near work still chemical and microbiological laboratory, but there outsiders are not allowed).

This is a book with the corporate guideline on buns. It contains detailed information about what the proper bun is different from wrong.

In the upper left corner - Photo correct ideal surface rolls, to strive. On the other three pictures show various defects. Similarly, on other pages clearly understand other parameters rolls: dusting sesame ("correct dusting", "too much sesame", "too little sesame", "uneven dusting"), cutting, shape, color, structure, size, absence of pits and so on. Well, that is a statement that on the way to the consumer hamburger takes about hundreds of tests, it is true that if you take any object to measure its weight, color, shape, texture, microbiology, shaggy, roughness, splendor, humidity, elongation at break , elasticity, transparency, etc., and even repeat the assessment several times - at the entrance of raw materials in the manufacturing process and the output - you probably will not lower.

There assess the quality of the finished product from each batch.

In the laboratory, found exactly the same equipment as in all restaurants, "McDonald's". Therefore, it suffices to take the neighborhood made a standard bun, place it in a standard toaster (pre-programmed for standard frying time rolls) and to assess whether the result meets the high standards of the company. In the same way everything else is tested (from vegetables to cocktails), but we'll see how we study the buns.

For comparison, the left and center - defective rolls, right - right, high-quality bun.

Results of the study rolls (each parameter is given a separate evaluation) fit into a questionnaire. If bun curves obtained improperly sliced, sprinkled with sesame seeds uneven, too pale, and pitted, then the lot is rejected. If bun fit into the established standards, the party passed.

Ideal for the bun "Big Mac».

This photo shows a special cardboard instrument for assessing the correctness of size and evenness of cutting buns for hamburgers / cheeseburgers (top notch), "Big Mac" (left) and "Royal" (bottom). "We need to - say - beg you this device to go with him to the nearest" McDonald's "and meticulously measure rolls directly on the counter." "And this device, - answer me - and so every restaurant there: they also conduct tests and discarded if necessary».

The tour ended and we went back into the hall "McComplex", where a commemorative marble tablet Soviet hammer and sickle is adjacent to the Canadian Maple Leaf.

via nl