502

The inspection pit: the features of the device and installation

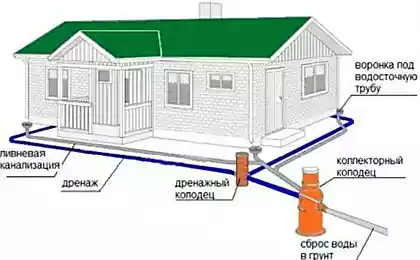

All utility structures (sewer or drainage pipelines are no exception) are regularly subjected to routine inspection and maintenance. Proper control of the state of the system and its operation – the key to trouble-free operation of communications. For maintenance of sewer and drainage pipelines are used, special manholes, United in a common network. Design necessarily installed on the system where changing the diameter of its tubes, the direction of runoff, etc.

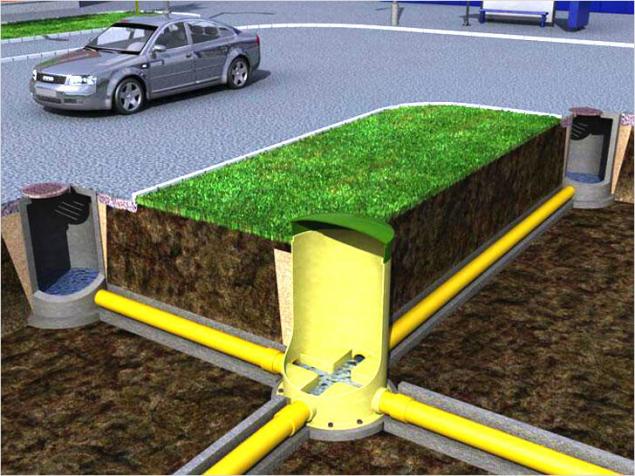

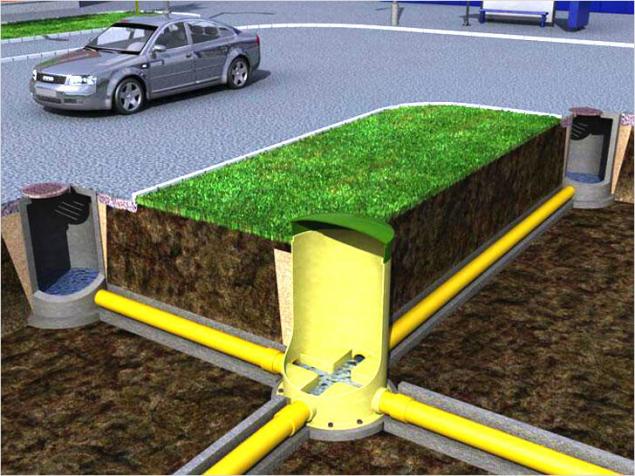

The inspection pit is used for visual control over the condition of underground utilities. The device is designed in such a way that if necessary it was possible with the help of special equipment to carry out cleaning the clogged pipeline. The design of the well is very simple. All varieties have common elements: a base, a tray, a working chamber, and the neckline, which closes the sunroof. The shape can be any, but most often they are round or quadrangular. The size of the working chamber also differ. If it is assumed that inside of it will work man, its height should be at least 1800 mm.

There are several types of manholes, differing from each other in design and purpose. On the straights communications at an equal distance from each other set of the linear design. Their location depends on the diameter of laid pipes. For example, 50 mm details of linear wells are installed every 35 m of 200 mm elements – 50 m 500 mm 75 m and so on.

At points where a branch changes direction, install with swivel design. Their peculiarity lies in the fact that the trays are of such wells have a rounded shape that closely follows the trajectory of the turn.

On segments of the pipeline where the runoff velocity is low, sediment is deposited. Over time it can completely block the pipe, so there definitely are special rinsing and washing the wells. The device is designed in such a way that allows to flush the communications.

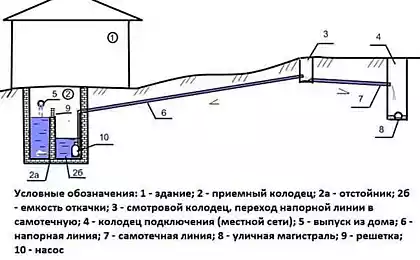

On the pipeline sections where the levels of the inlet and outlet of the element are not the same, set flow and pressure drop wells. Feature of the device lies in the fact that the trays they are located at different heights.

At points of connections of street and yard systems settling in the control wells. According to the rules they can't be within the red line development.

In addition, in areas where multiple branches are joined, usually mounted in a hub well. It combines two or three lead-in items from one outlet.

Manholes are usually concrete structures. The base plate of reinforced concrete is placed on the gravel. The tray is mounted on top of reinforced concrete, which is manufactured according to a special template. The surface of the pan should be smooth, so it is always overwritten. The well is equipped so that the pipe underground utilities were connected with the tray, and leaking sewage.

The height of the trays is selected so that it was larger than the diameter of sewer pipes. On both sides of the tray are mounted bench. The so-called shelves, which during the work to fit the workers. The walls of the well shall be equipped with brackets for easy descent.

Luke, which ends with the working chamber, performs several tasks. It prevents accidents, which are inevitable when human fall in the well. In addition, the hatch protects the camera against soiling. On the neck cover fit the device. It can be made of cast iron or special highly durable plastic. Metal parts have great weight, but they are the most durable. That is why they are usually placed on the roadway.

A good alternative to concrete inspection steel well plastic design. The shaft of the corrugations can easily change their sizes. This is especially important for areas where large seasonal temperature swings. Pleated elements change their dimensions or warp during the freezing and thawing of the soil. Light weight plastic device makes installation quick and simple. Special equipment is not required. In addition, plastic containers are sealed and have a long service life, which is a few tens of years.

The construction cost of plastic is high enough, so in some cases, the cost to purchase items individually. For installation you will need corrugated pipe, the bottom and the rubber seals. The pipe diameter is selected based on the intended use of the device. For the well that will not fall, will be enough of the element with a diameter of 460 mm for the other designs choose the pipe section from 925 mm. In the interval of the corrugations in the desired length are the holes in the pipe. Then in the ditch where the route of communication, settling under the bottom of the well.

It is prepared and secured design. Inside the well through the seal start of the pipe. Parts of the joints are carefully sealed. In a similar way it is manufactured and installation of concrete structures. First, the settling bottom, for a set, the trays and walls of concrete rings. The main difficulty faced during installation is a large weight of items. They can only be moved with special equipment.

Manholes is an integral part of the sewer or drainage system. Their proper arrangement will provide an opportunity for conducting necessary preventive maintenance, which ensures smooth operation of utilities.

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: www.stroitelstvo365.ru/kanalizatsionnie-sistemi/smotrovoj-kolodets-osobennosti-ustrojstva-i-montazha

The inspection pit is used for visual control over the condition of underground utilities. The device is designed in such a way that if necessary it was possible with the help of special equipment to carry out cleaning the clogged pipeline. The design of the well is very simple. All varieties have common elements: a base, a tray, a working chamber, and the neckline, which closes the sunroof. The shape can be any, but most often they are round or quadrangular. The size of the working chamber also differ. If it is assumed that inside of it will work man, its height should be at least 1800 mm.

There are several types of manholes, differing from each other in design and purpose. On the straights communications at an equal distance from each other set of the linear design. Their location depends on the diameter of laid pipes. For example, 50 mm details of linear wells are installed every 35 m of 200 mm elements – 50 m 500 mm 75 m and so on.

At points where a branch changes direction, install with swivel design. Their peculiarity lies in the fact that the trays are of such wells have a rounded shape that closely follows the trajectory of the turn.

On segments of the pipeline where the runoff velocity is low, sediment is deposited. Over time it can completely block the pipe, so there definitely are special rinsing and washing the wells. The device is designed in such a way that allows to flush the communications.

On the pipeline sections where the levels of the inlet and outlet of the element are not the same, set flow and pressure drop wells. Feature of the device lies in the fact that the trays they are located at different heights.

At points of connections of street and yard systems settling in the control wells. According to the rules they can't be within the red line development.

In addition, in areas where multiple branches are joined, usually mounted in a hub well. It combines two or three lead-in items from one outlet.

Manholes are usually concrete structures. The base plate of reinforced concrete is placed on the gravel. The tray is mounted on top of reinforced concrete, which is manufactured according to a special template. The surface of the pan should be smooth, so it is always overwritten. The well is equipped so that the pipe underground utilities were connected with the tray, and leaking sewage.

The height of the trays is selected so that it was larger than the diameter of sewer pipes. On both sides of the tray are mounted bench. The so-called shelves, which during the work to fit the workers. The walls of the well shall be equipped with brackets for easy descent.

Luke, which ends with the working chamber, performs several tasks. It prevents accidents, which are inevitable when human fall in the well. In addition, the hatch protects the camera against soiling. On the neck cover fit the device. It can be made of cast iron or special highly durable plastic. Metal parts have great weight, but they are the most durable. That is why they are usually placed on the roadway.

A good alternative to concrete inspection steel well plastic design. The shaft of the corrugations can easily change their sizes. This is especially important for areas where large seasonal temperature swings. Pleated elements change their dimensions or warp during the freezing and thawing of the soil. Light weight plastic device makes installation quick and simple. Special equipment is not required. In addition, plastic containers are sealed and have a long service life, which is a few tens of years.

The construction cost of plastic is high enough, so in some cases, the cost to purchase items individually. For installation you will need corrugated pipe, the bottom and the rubber seals. The pipe diameter is selected based on the intended use of the device. For the well that will not fall, will be enough of the element with a diameter of 460 mm for the other designs choose the pipe section from 925 mm. In the interval of the corrugations in the desired length are the holes in the pipe. Then in the ditch where the route of communication, settling under the bottom of the well.

It is prepared and secured design. Inside the well through the seal start of the pipe. Parts of the joints are carefully sealed. In a similar way it is manufactured and installation of concrete structures. First, the settling bottom, for a set, the trays and walls of concrete rings. The main difficulty faced during installation is a large weight of items. They can only be moved with special equipment.

Manholes is an integral part of the sewer or drainage system. Their proper arrangement will provide an opportunity for conducting necessary preventive maintenance, which ensures smooth operation of utilities.

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: www.stroitelstvo365.ru/kanalizatsionnie-sistemi/smotrovoj-kolodets-osobennosti-ustrojstva-i-montazha

Scientists from the UAE have learned to set the function content

How to double the yield - 10 useful tips