508

How to make a lamp out of wood with your own hands

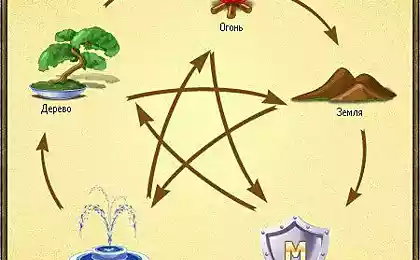

In skilled hands, the tree becomes a truly magical material. In addition to furniture, for the manufacture of which uses valuable breeds of wood, they waste wood on the basis of which creates the hybrid wood. The tree lends itself well to gluing. Wood is bent rafter system in the form of Lancet arches.

The flexibility of wood and the ability to give to it any form got American designer Field Voeckler who decided to make "pieces of wood" a quirky and stylish lamp.

Paul decided to cut all superfluous and, thus, to emphasize the texture of wood. Clearing churbachki from the bark, the designer has split them into several parts. However, he is not trying to achieve perfect symmetry or to use machines. Felt like walked hand. The result is several pieces, different from each other.

After that, Paul cut Polenz across several parts. Further, pushing the core, the designer took the metal rod and strung on a sections, and mounted inside the led lamp.

Externally, the lamp something like a spine, made of wood. The asymmetry of the product only highlights its unusual shape.To improve heat removal from the working bulb to the bottom of the lamp punched aluminum core radiator.

Depending on the lamp size and the chosen form, it can be put on the table (from the bottom are rubberized feet), or to attach metal feet to set on the floor.

In order to emphasize the tree structure and texture of the tree rings, but "not to score" the natural look of wood, billet cover with a colourless varnish. The lamp turned out so successful and popular that Paul decided to put the matter on the flow and created an original series of lamps. Moreover, none of the product does not repeat the previous one. The shape, size, width of cut, saturation of the light flux, which gives light — all this gives the work a uniqueness and individuality. Depending on the complexity of the product, the manufacture of one lamp can take up to 100 hours.Paul says, anyone who is going to do a similar thing, it is important to find "their" tree. The designer uses the Californian cypress and wood ash.

For example, the designer combines grinding with a coarse chopped forms.

This reveals and emphasizes the natural wood texture and enhances the effect of the lamp.

Paul also advises to experiment with the distance between the slices.

To increase or decrease this distance or by combining both methods, you can achieve the same effect at some angles, the tree will look like a solid array, inside which flows the light was dim. published

Source: www.forumhouse.ru/articles/house/6849

The flexibility of wood and the ability to give to it any form got American designer Field Voeckler who decided to make "pieces of wood" a quirky and stylish lamp.

Paul decided to cut all superfluous and, thus, to emphasize the texture of wood. Clearing churbachki from the bark, the designer has split them into several parts. However, he is not trying to achieve perfect symmetry or to use machines. Felt like walked hand. The result is several pieces, different from each other.

After that, Paul cut Polenz across several parts. Further, pushing the core, the designer took the metal rod and strung on a sections, and mounted inside the led lamp.

Externally, the lamp something like a spine, made of wood. The asymmetry of the product only highlights its unusual shape.To improve heat removal from the working bulb to the bottom of the lamp punched aluminum core radiator.

Depending on the lamp size and the chosen form, it can be put on the table (from the bottom are rubberized feet), or to attach metal feet to set on the floor.

In order to emphasize the tree structure and texture of the tree rings, but "not to score" the natural look of wood, billet cover with a colourless varnish. The lamp turned out so successful and popular that Paul decided to put the matter on the flow and created an original series of lamps. Moreover, none of the product does not repeat the previous one. The shape, size, width of cut, saturation of the light flux, which gives light — all this gives the work a uniqueness and individuality. Depending on the complexity of the product, the manufacture of one lamp can take up to 100 hours.Paul says, anyone who is going to do a similar thing, it is important to find "their" tree. The designer uses the Californian cypress and wood ash.

For example, the designer combines grinding with a coarse chopped forms.

This reveals and emphasizes the natural wood texture and enhances the effect of the lamp.

Paul also advises to experiment with the distance between the slices.

To increase or decrease this distance or by combining both methods, you can achieve the same effect at some angles, the tree will look like a solid array, inside which flows the light was dim. published

Source: www.forumhouse.ru/articles/house/6849