865

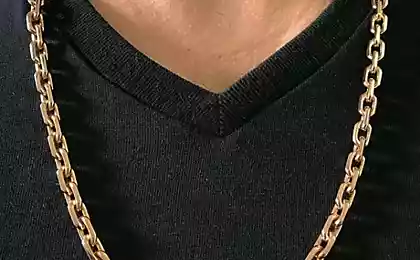

3D-press for jewelers: silver cufflinks with the hero of your favorite movie

3D-printed jewel of exclusive design - an original gift to a friend, and a great way to stand out and emphasize their individuality.

We all have favorite characters, games and movies - animated and artistic. Popular characters can often be seen on someone's T-shirt, bag, cap, scarf, calendars, mugs and other media. If you know a movie or a character like a man, for which you want to make a gift, it is easy to please him in this article of clothing or kitchen utensils. But how often have you had to give to a friend (or a favorite) cufflinks depicting a favorite movie character?

It is decided to make one of our customers to see on the site Prototypster 3D-model of cufflinks with the image of the hero of Jim Carrey from the movie " Mask ". 3D-model of created 3D-talented designer Gregory Krasnoperov (nickgrinnt online Prototypster.ru) and attracted the attention of quality performance and detail.

In addition, Gregory great pleasure to create their favorite character:

«It was originally a statue-bust" Mask », smodelennaya back in 2012. This is one of my favorite characters of 90th, so sculpting for pleasure ». I>

3D-model of the bust of Gregory did in Zbrush:

«All the work is kept within 3-4 hours, after which I did and removed render the model in the" archive ", where it has lain 2, 5 years. Just not so long ago, I took her out of the bins, and decided to prepare a bust to the 3D-printing. And then from this model were made back and cuff links, at the request of the customer » i>

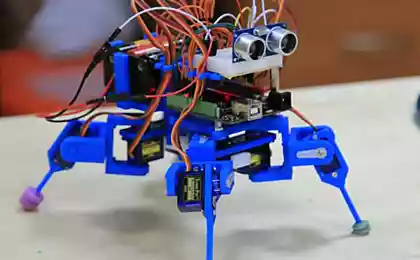

For cufflinks customer selected material - silver. The model was prepared for publication by engineers Prototypster and then, with help of 3D-printing and jewelers, brought to life.

Fabrication process included several steps. First, on a professional jewelry 3D-printer was manufactured stencil for 3D-model designer grinnt . Manufacturing technology, which operates at the printer - laser stereolithography (SLA) and the material - yellow photopolymer - together yielded high detail and precision, literally "jewelry."

In the preparation of 3D-model to the press, the engineer must be remembered that the pattern for the future of the casting must be greater than the final model by about 3%, taking into account the shrinkage of the material and mechanical post-processing. Next, the master model is sent to the casting: stencil is placed in the molding sand (gypsum) and heated to evaporate the master model. Further, the resulting shape is filled metal (in this case silver). Then you need to give the metal to cool, remove and process the product, polish it - and this is the perfect gift for a loved one is ready.

If you want to be the proud owner of 3D-printed jewel, go to marketpleys Prototypster and choose your favorite model! We also create custom jewelry design - just email us at mail ]

Source: geektimes.ru/company/prototypster/blog/263882/

We all have favorite characters, games and movies - animated and artistic. Popular characters can often be seen on someone's T-shirt, bag, cap, scarf, calendars, mugs and other media. If you know a movie or a character like a man, for which you want to make a gift, it is easy to please him in this article of clothing or kitchen utensils. But how often have you had to give to a friend (or a favorite) cufflinks depicting a favorite movie character?

It is decided to make one of our customers to see on the site Prototypster 3D-model of cufflinks with the image of the hero of Jim Carrey from the movie " Mask ". 3D-model of created 3D-talented designer Gregory Krasnoperov (nickgrinnt online Prototypster.ru) and attracted the attention of quality performance and detail.

In addition, Gregory great pleasure to create their favorite character:

«It was originally a statue-bust" Mask », smodelennaya back in 2012. This is one of my favorite characters of 90th, so sculpting for pleasure ». I>

3D-model of the bust of Gregory did in Zbrush:

«All the work is kept within 3-4 hours, after which I did and removed render the model in the" archive ", where it has lain 2, 5 years. Just not so long ago, I took her out of the bins, and decided to prepare a bust to the 3D-printing. And then from this model were made back and cuff links, at the request of the customer » i>

For cufflinks customer selected material - silver. The model was prepared for publication by engineers Prototypster and then, with help of 3D-printing and jewelers, brought to life.

Fabrication process included several steps. First, on a professional jewelry 3D-printer was manufactured stencil for 3D-model designer grinnt . Manufacturing technology, which operates at the printer - laser stereolithography (SLA) and the material - yellow photopolymer - together yielded high detail and precision, literally "jewelry."

In the preparation of 3D-model to the press, the engineer must be remembered that the pattern for the future of the casting must be greater than the final model by about 3%, taking into account the shrinkage of the material and mechanical post-processing. Next, the master model is sent to the casting: stencil is placed in the molding sand (gypsum) and heated to evaporate the master model. Further, the resulting shape is filled metal (in this case silver). Then you need to give the metal to cool, remove and process the product, polish it - and this is the perfect gift for a loved one is ready.

If you want to be the proud owner of 3D-printed jewel, go to marketpleys Prototypster and choose your favorite model! We also create custom jewelry design - just email us at mail ]

Source: geektimes.ru/company/prototypster/blog/263882/

Saver: In case of fire use a breath of fresh air

25 Pets, who realized that they had been betrayed and carry to the vet