1542

How are made robot cleaners Yujin Robot factory in Korea?

Robotic vacuum cleaners every day are becoming increasingly popular. Many potential consumers still formed the opinion that it is just a toy. Often this is due either to a lack of understanding of the principle of operation of the gadget, or reviews from friends who had once bought a Chinese equivalent for a small price and disappointed in the quality of cleaning and the reliability of the device. I will not convince you in this article is that the robot cleaner necessary thing in life. In our shop had a lot of feedback from customers who have no idea how they even lived without automatic cleaner. But on more than I wanted to stay, so it's on the production of the most popular at the moment (according to Яндекс.Маркет) robots iClebo Korean company Yujin Robot. I personally was able to visit the production line Yujin Robot and the head office in Seoul, enclosing a small report.

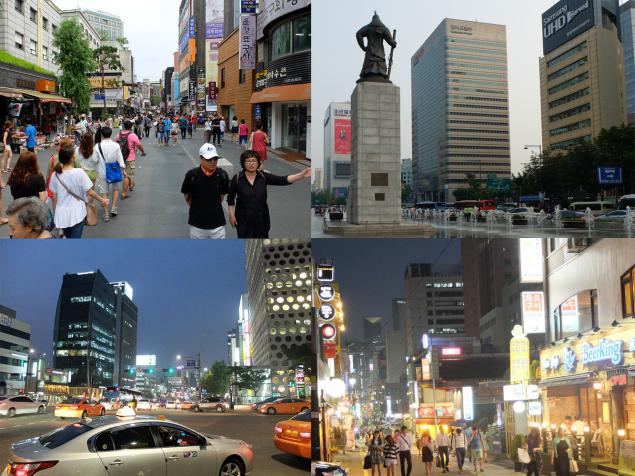

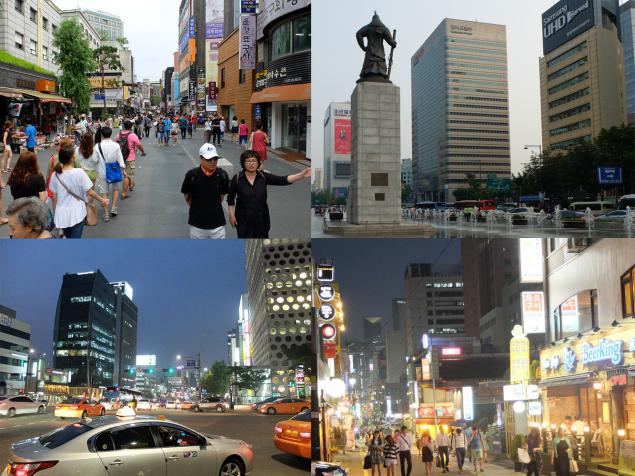

Unlike most other companies manufacturers of robotic vacuum cleaners, Yujin Robot not moved their production to China, and located within walking distance from the head office in Seoul. Seoul - metropolis and the main business center of South Korea. All the streets are full of bright advertising known Korean brands at numerous skyscrapers: Samsung (perhaps brand №1 in Korea), LG, Hyundai and others. The population density per unit area is quite high, even late in the evening on the main streets is not overcrowded (eg, in the streets of Gangnam area, which has all the favorite famous song Gangnam Style).

Generally speaking, there are still a lot of fans all singer Psy and whenever possible and catch all dancing to the fiery rhythm of the song.

The company is headquartered in the city area Geumcheon District in BC Namseong Plaza on the 6th and the 12th floor. On the ground floor sits a team of developers and technicians testing department, polygons and automated systems for testing, as well as a museum of past and current developments. By the way, Yujin Robot does not pay for the lease of these stories, because in Korea made not just rent an office, and to redeem the area forever, as we have an apartment. Yujin bought two floors of the business center.

On the top floor - sales people, programmers, marketing, management.

Today, the company is investing major force in the development and manufacture of robotic vacuum cleaners iClebo, as the most popular and promising direction (although different kinds proizvodsvennye lines and handles custom Yujin also produces). Current models of robot vacuum cleaners from Yujin Robot as of this writing: iClebo Arte (robot with a system of mapping the room) and iClebo Pop (younger brother without a camera, odometer, gyroscope and cleaning timer).

The very same factory and warehouse are located in the suburbs of Seoul - Bucheon, in the area of industrial park, where the focus different technology companies in South Korea (something similar to our Skolkovo). In one of the buildings of the Technopark is a production line and warehouse Yujin Robot. To the left of the main entrance, there is a zone of shipment, where you can adjust the truck and load pallets of robots. Yujin occupies several floors in Technopark.

Before entering the industrial park:

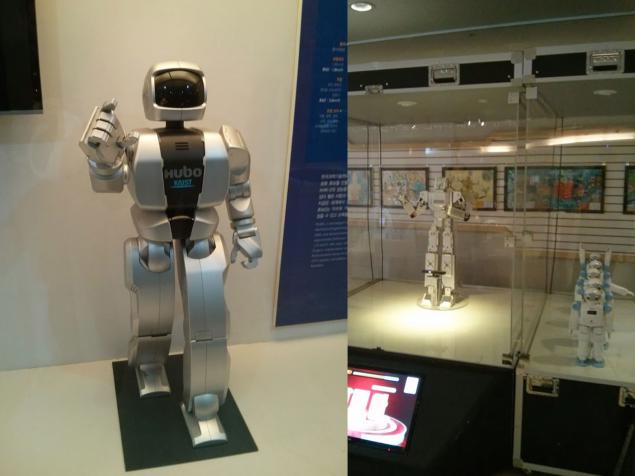

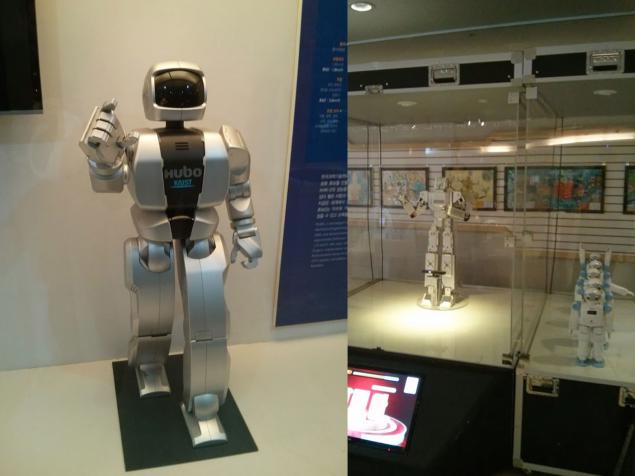

In the industrial park are some Korean companies, all of which are involved in the production of robots (both domestic and industrial). At the bottom is a museum, which displays robots Roboparka companies.

Close to humanoid robots,

play golf,

established stand of Hyunday with industrial robots,

as well as the robot for education of children from iRobiQ company Yujin Robot (quite popular in Korea, but is not available in Russian).

Korean children are sometimes so confusing:

And Asian manufacturers also like to try something sort of, like to stick to the cover of the robot pearl pattern (pattern material - seashells):

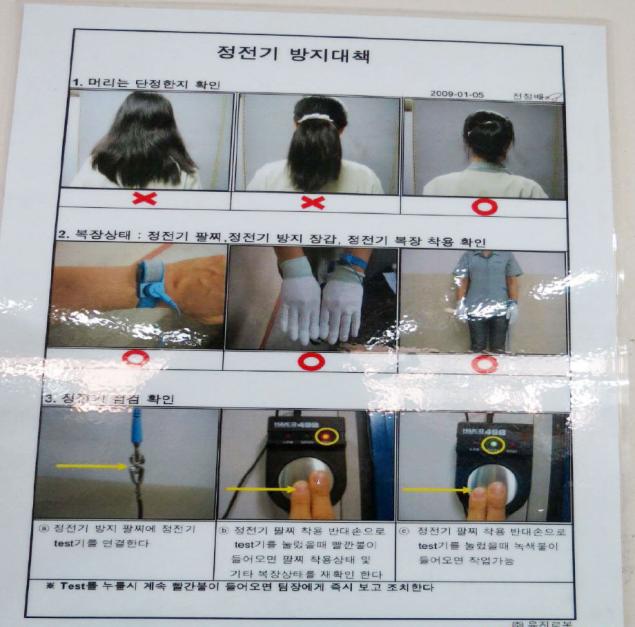

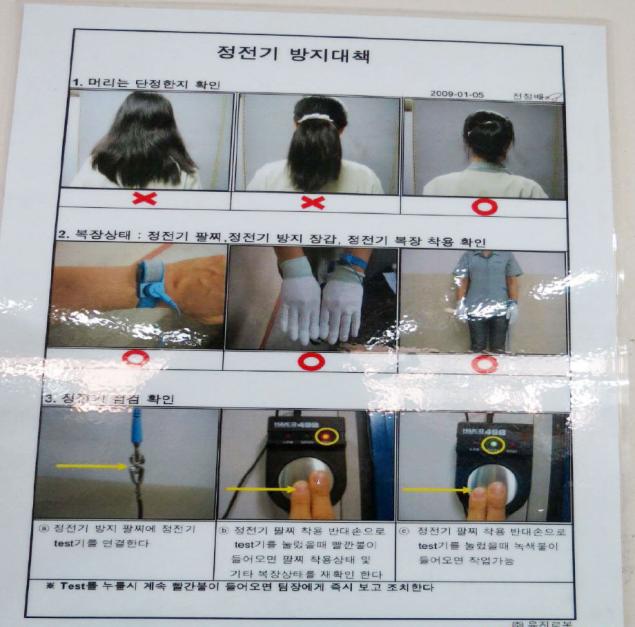

Go ahead, directly to the factory. Outsiders (like me) have to necessarily change one's shoes in rubber slippers. For full-time employees on the wall hang the rules. Women, for example, you can not have long hair, so if you are a lover of long hair, then this job is not for you.

All staff grounded and wear gloves.

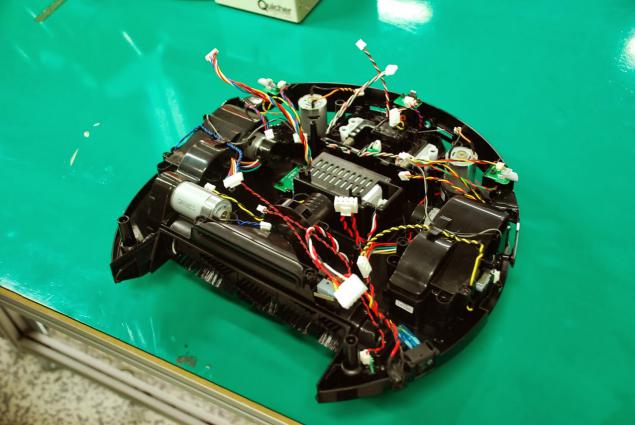

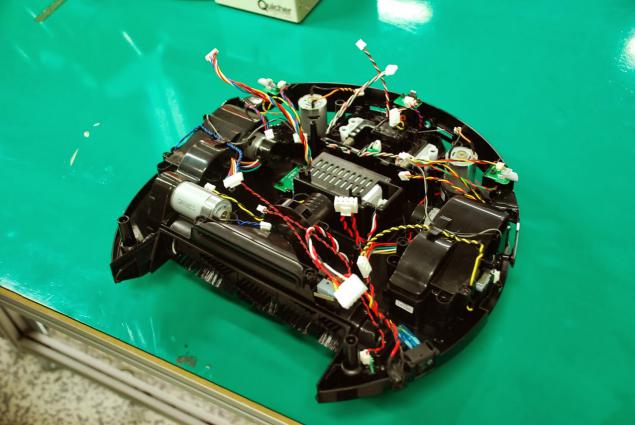

Entering the room, we have a production line.

At each stage of the factory employee performs only their jobs, such as employee (most of the staff of the production line - a woman) goes on here this robot assembly stage:

Its goal to tie the motherboard. The task of the next employee to connect all the cables to the connectors on the motherboard. All stages of assembly are divided into very small steps. This approach allows us to increase the accuracy and build quality.

After the build robots get to the test site.

They checked twice before packing in a box. Checked without fail each robot (which did not make many other manufacturers, particularly in China). Percentage of defects from the factory tend to zero.

First, check the operation of all sensors via the service menu of the robot cleaner, then iClebo chase on all sorts of landfills in order to further test the build quality and performance of the device.

After careful inspection and packing, robots sent to the warehouse where are another quality control. From each batch of 50 iClebo, 10 vacuum cleaners are chosen arbitrarily and fully tested again. If marriage is not found, the robots are sent to dealers, but if detected marriage, the whole party goes on additional testing.

And here is our robots who will travel a few hours to Moscow. Perhaps, it is necessary to write something nice on our boxes.

If you have any further questions, I will be glad to answer them. All the best!

Source: geektimes.ru/post/246994/

Unlike most other companies manufacturers of robotic vacuum cleaners, Yujin Robot not moved their production to China, and located within walking distance from the head office in Seoul. Seoul - metropolis and the main business center of South Korea. All the streets are full of bright advertising known Korean brands at numerous skyscrapers: Samsung (perhaps brand №1 in Korea), LG, Hyundai and others. The population density per unit area is quite high, even late in the evening on the main streets is not overcrowded (eg, in the streets of Gangnam area, which has all the favorite famous song Gangnam Style).

Generally speaking, there are still a lot of fans all singer Psy and whenever possible and catch all dancing to the fiery rhythm of the song.

The company is headquartered in the city area Geumcheon District in BC Namseong Plaza on the 6th and the 12th floor. On the ground floor sits a team of developers and technicians testing department, polygons and automated systems for testing, as well as a museum of past and current developments. By the way, Yujin Robot does not pay for the lease of these stories, because in Korea made not just rent an office, and to redeem the area forever, as we have an apartment. Yujin bought two floors of the business center.

On the top floor - sales people, programmers, marketing, management.

Today, the company is investing major force in the development and manufacture of robotic vacuum cleaners iClebo, as the most popular and promising direction (although different kinds proizvodsvennye lines and handles custom Yujin also produces). Current models of robot vacuum cleaners from Yujin Robot as of this writing: iClebo Arte (robot with a system of mapping the room) and iClebo Pop (younger brother without a camera, odometer, gyroscope and cleaning timer).

The very same factory and warehouse are located in the suburbs of Seoul - Bucheon, in the area of industrial park, where the focus different technology companies in South Korea (something similar to our Skolkovo). In one of the buildings of the Technopark is a production line and warehouse Yujin Robot. To the left of the main entrance, there is a zone of shipment, where you can adjust the truck and load pallets of robots. Yujin occupies several floors in Technopark.

Before entering the industrial park:

In the industrial park are some Korean companies, all of which are involved in the production of robots (both domestic and industrial). At the bottom is a museum, which displays robots Roboparka companies.

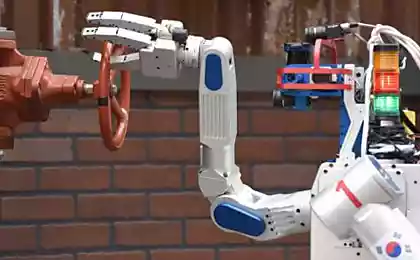

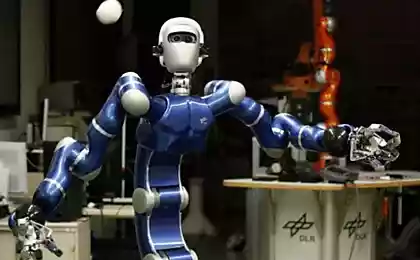

Close to humanoid robots,

play golf,

established stand of Hyunday with industrial robots,

as well as the robot for education of children from iRobiQ company Yujin Robot (quite popular in Korea, but is not available in Russian).

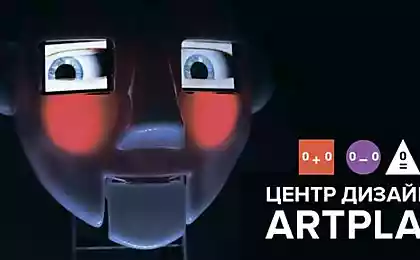

Korean children are sometimes so confusing:

And Asian manufacturers also like to try something sort of, like to stick to the cover of the robot pearl pattern (pattern material - seashells):

Go ahead, directly to the factory. Outsiders (like me) have to necessarily change one's shoes in rubber slippers. For full-time employees on the wall hang the rules. Women, for example, you can not have long hair, so if you are a lover of long hair, then this job is not for you.

All staff grounded and wear gloves.

Entering the room, we have a production line.

At each stage of the factory employee performs only their jobs, such as employee (most of the staff of the production line - a woman) goes on here this robot assembly stage:

Its goal to tie the motherboard. The task of the next employee to connect all the cables to the connectors on the motherboard. All stages of assembly are divided into very small steps. This approach allows us to increase the accuracy and build quality.

After the build robots get to the test site.

They checked twice before packing in a box. Checked without fail each robot (which did not make many other manufacturers, particularly in China). Percentage of defects from the factory tend to zero.

First, check the operation of all sensors via the service menu of the robot cleaner, then iClebo chase on all sorts of landfills in order to further test the build quality and performance of the device.

After careful inspection and packing, robots sent to the warehouse where are another quality control. From each batch of 50 iClebo, 10 vacuum cleaners are chosen arbitrarily and fully tested again. If marriage is not found, the robots are sent to dealers, but if detected marriage, the whole party goes on additional testing.

And here is our robots who will travel a few hours to Moscow. Perhaps, it is necessary to write something nice on our boxes.

If you have any further questions, I will be glad to answer them. All the best!

Source: geektimes.ru/post/246994/

In Venezuela will install 20,000 fingerprint scanners in grocery stores to deal with speculators

Lockheed Martin answers questions on the laser system ATHENA