1011

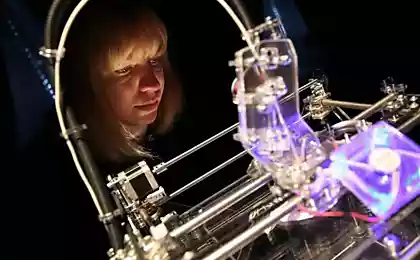

Scientists have found a way to control the liquid metal, changing its surface tension

Researchers from North Carolina State University have developed a simple and elegant way to widely change the surface tension of the liquid metal droplets , the thus changing their shape. Scientists have used an alloy of 75% to 25% gallium and indium, having a melting point just 15 5 degrees Celsius. A drop of this alloy is placed in an electrolyte solution takes the form of nearly spherical due to the high surface tension (about 500 mJ / m 2 sup>). However, if you apply for a small metal, only about 1 volt, the voltage drop is formed on the surface of a very thin oxide layer, which reduces the surface tension to near zero, 250 times. Gravity drop instantly spreads in a flat "pancake". The most interesting - these changes are completely reversible, is only a negative voltage is applied, as the oxide layer is destroyed, and the drop recovers its shape.

By varying the voltage, it is possible to control the shape of a wide range of metal droplets in the solution causes the metal to flow through thin capillaries of make and break electrical contacts. It can be used in MEMS and electro-optical devices, mikroaktuatorah, reconfigurable antennas that can take different forms. The oxide film may occur under the influence of electricity on the surface of a plurality of metals and alloys, and not only in solutions. Last year, the same team of researchers has demonstrated 3D-printing liquid metal in air at room temperature - drops of molten metal immediately "froze" due to all of the same oxide film:

Source: habrahabr.ru/post/239721/

By varying the voltage, it is possible to control the shape of a wide range of metal droplets in the solution causes the metal to flow through thin capillaries of make and break electrical contacts. It can be used in MEMS and electro-optical devices, mikroaktuatorah, reconfigurable antennas that can take different forms. The oxide film may occur under the influence of electricity on the surface of a plurality of metals and alloys, and not only in solutions. Last year, the same team of researchers has demonstrated 3D-printing liquid metal in air at room temperature - drops of molten metal immediately "froze" due to all of the same oxide film:

Source: habrahabr.ru/post/239721/

Successful and unsuccessful expedition to Mars and Mars orbit: infographics

Exoskeletons in medicine