631

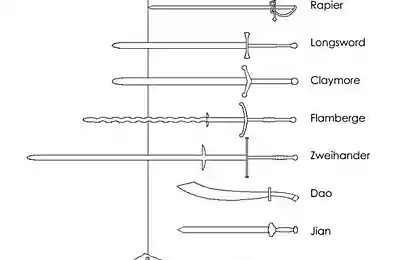

As I Nepalese kukri gash,

The logical continuation of the theme, which I promised to show the process of making the Nepalese kukri.

Doing so, it allowed the radius of curvature of my hands, so ready to receive comments and tips rukozhopov true.

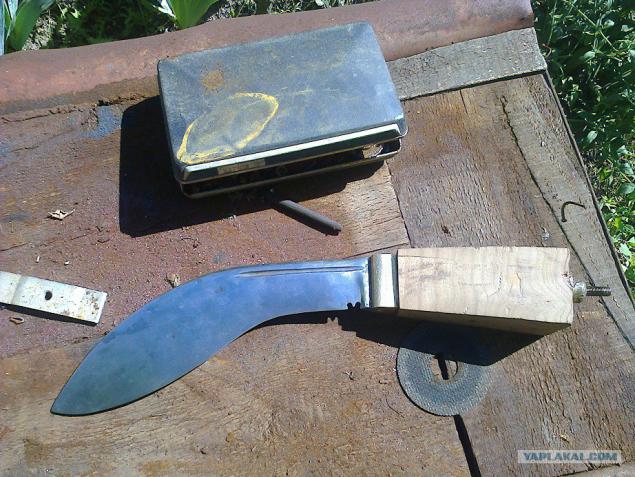

First, it was spring, roofing by KAMAZ, whether from a tractor trailer, thick and heavy infection. To her by electric welded handle.

To dull the blade forging, as well as the occupation is in two hands takes all the attention and the same hand and the pictures do not work a lot ...

And so

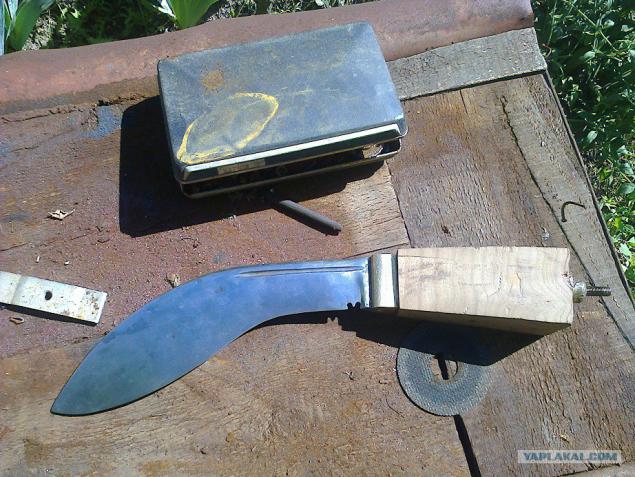

Eventually get just such a blank

Home slesarki ...

Get in the end is here ...

Time hardening, heat-resistant sealant make the plaster, in order to quench zone and turned the output butt was soft and strong cutting edge. The fly is not mine, just flew look.

Kalit decided on the black American walnut (shell is thick and very strong when the core burn out already give a lot of heat).

Here is a wedge almost immediately after quenching, the right of the hearth tube, is the capacity for hardening - where oil 3 to 1 transformer and sunflower.

Brush from scale and plaster, the blade is visible boundary hardening, grinding and polishing after it became invisible, but it can at any time express with acid.

Another

Started doing bolster, but as the tech could not find a piece of brass that the desired thickness had to build just such a muffle furnace

From the shape of the profile it has been made successfully melted brass faucet and cast a small brick-bread

Another photo casting

cut off the excess received such a brusochek

I mark up, and began to cut into the brass cubes place in the blade

And yet, in general, did a photo Dremel did the Chinese, and the quality of this, so do not blame me.

Since the load on a knife involves not children, it was decided to bolster put on the tin, a wedge, so as not to screw hardened pre wrapped a wet towel.

On the knob was selected basal portion of the cap wild olive

Mounting through-hole is filled with epoxy as a filler - brass filings, grated horn and wood chips.

Here's a heel

That's what got

I start to grind handle

And yet

The result is such a thing has turned

But in the morning I handle this with no regrets split the hammer on the anvil, and began to make a new suveli of apricot.

More in this time to the second time to kill the casting muffle furnace, as there was no thermostat, the heat for half an hour managed to fall down the spiral, magnesite plate with asbestos cement koltsom- there, scorched order mineral wool.

Due to the death of mufelki, tylnik decided to solder. It was taken by brass nut and purchased a suitable fitting.

Pike did with the inside of the hard solder.

The second part of the ballet marlezonskogo, grind handle

Next

Non-stop ... suvel apricot - is a stone that weight, that hardness, and the sweet smell at all difficult to convey in words - like honey

After polishing and arm and a wedge that's got a knife

Sheath - your turn came, I began to collect them from plywood

Wooden frame consists of 3 parts - the two pads and proper place under the knife.

The first attempt was made here of the sheath in such a Makarov, but slightly miscalculated and decided to redo already using plywood, as an order of magnitude less crap.

Plywood glued together, so strubtsinok I just pulled two parts here so

Deviate from the topic, introduced a cot and sleep on the street - fresh air and night-bird - beauty.

Grind, gives shape to the scabbard on his miracle machine

Better than perebdet nedobdet, machined grooves on the sheath and the entire structure, in addition to glue contracted stainless steel wire.

Wet leather scabbard were covered - that's turned a tight sock, after impregnation and subsequent warm wax - he was tough.

Helpers

Drink tea and think what to do next, I'm on the skin you - and for me all scary and creepy.

Spout sheath wrapped masking tape, then cut it - turned out pattern for ferrules

After soldering was such okovochka

He started manufacturing belt clip - tails for the convenience of pre-pasted

Nasverlil holes seams

Sew

He gathered all together

Doing so, it allowed the radius of curvature of my hands, so ready to receive comments and tips rukozhopov true.

First, it was spring, roofing by KAMAZ, whether from a tractor trailer, thick and heavy infection. To her by electric welded handle.

To dull the blade forging, as well as the occupation is in two hands takes all the attention and the same hand and the pictures do not work a lot ...

And so

Eventually get just such a blank

Home slesarki ...

Get in the end is here ...

Time hardening, heat-resistant sealant make the plaster, in order to quench zone and turned the output butt was soft and strong cutting edge. The fly is not mine, just flew look.

Kalit decided on the black American walnut (shell is thick and very strong when the core burn out already give a lot of heat).

Here is a wedge almost immediately after quenching, the right of the hearth tube, is the capacity for hardening - where oil 3 to 1 transformer and sunflower.

Brush from scale and plaster, the blade is visible boundary hardening, grinding and polishing after it became invisible, but it can at any time express with acid.

Another

Started doing bolster, but as the tech could not find a piece of brass that the desired thickness had to build just such a muffle furnace

From the shape of the profile it has been made successfully melted brass faucet and cast a small brick-bread

Another photo casting

cut off the excess received such a brusochek

I mark up, and began to cut into the brass cubes place in the blade

And yet, in general, did a photo Dremel did the Chinese, and the quality of this, so do not blame me.

Since the load on a knife involves not children, it was decided to bolster put on the tin, a wedge, so as not to screw hardened pre wrapped a wet towel.

On the knob was selected basal portion of the cap wild olive

Mounting through-hole is filled with epoxy as a filler - brass filings, grated horn and wood chips.

Here's a heel

That's what got

I start to grind handle

And yet

The result is such a thing has turned

But in the morning I handle this with no regrets split the hammer on the anvil, and began to make a new suveli of apricot.

More in this time to the second time to kill the casting muffle furnace, as there was no thermostat, the heat for half an hour managed to fall down the spiral, magnesite plate with asbestos cement koltsom- there, scorched order mineral wool.

Due to the death of mufelki, tylnik decided to solder. It was taken by brass nut and purchased a suitable fitting.

Pike did with the inside of the hard solder.

The second part of the ballet marlezonskogo, grind handle

Next

Non-stop ... suvel apricot - is a stone that weight, that hardness, and the sweet smell at all difficult to convey in words - like honey

After polishing and arm and a wedge that's got a knife

Sheath - your turn came, I began to collect them from plywood

Wooden frame consists of 3 parts - the two pads and proper place under the knife.

The first attempt was made here of the sheath in such a Makarov, but slightly miscalculated and decided to redo already using plywood, as an order of magnitude less crap.

Plywood glued together, so strubtsinok I just pulled two parts here so

Deviate from the topic, introduced a cot and sleep on the street - fresh air and night-bird - beauty.

Grind, gives shape to the scabbard on his miracle machine

Better than perebdet nedobdet, machined grooves on the sheath and the entire structure, in addition to glue contracted stainless steel wire.

Wet leather scabbard were covered - that's turned a tight sock, after impregnation and subsequent warm wax - he was tough.

Helpers

Drink tea and think what to do next, I'm on the skin you - and for me all scary and creepy.

Spout sheath wrapped masking tape, then cut it - turned out pattern for ferrules

After soldering was such okovochka

He started manufacturing belt clip - tails for the convenience of pre-pasted

Nasverlil holes seams

Sew

He gathered all together