326

Doing bench

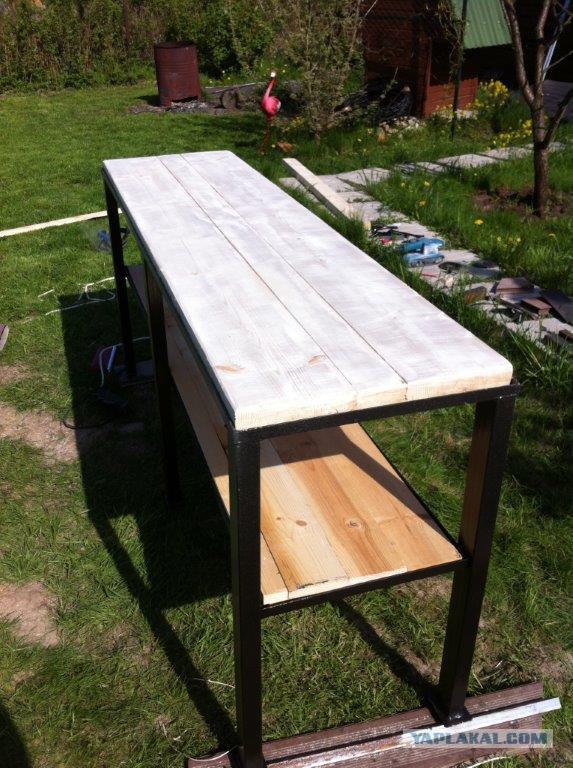

Dacha we build ourselves, polegonku quietly, without attracting rabsily side. The work is complete and all of it, of course, different. And very often it has something sawed-podstrogat-drill. We've all done it this time on the porch (the porch benefit of 2.5 * 7 meters). The porch is preserved a general view, but, as Bill Clinton said, "With this, Monica must stop." Therefore, we need a workbench. It already has a barn, where it can be put.

Of course, the purchase workbench - not our method, Shura. We will do ourselves.

Getting.

That's out of this pile of iron, bought the day before, it is necessary to make the Mighty verstachok with a shelf underneath. Sedentary work for the bench is not, so the regiment must be large in size, as full of tools that have nowhere to put, any chisels, gouges, planes and other Gamsakhurdia.

The framework for countertops and shelves - 4mm area. Shelf appears to 25mm.

Feet - 60 * 2mm proftruba 40

Heel - 2 mm sheet metal.

Will be 24 photos.

Smoke break, kofeek, removal tool.

For all the work we need:

1. The Bulgarian (preferably two - cleaned and cut).

2. The welding machine electrodes + + + mask slag hammer + brush + leggings + welding robe

3. Corner + pencil + roulette

4. Clamps and conventional 90-degree

5. The mask stripper joints

6. Grind + 60 and 120 tapes

7. Hand Circular Saw

8. + Nail brush

We start with a framework for countertops. Saw off corner sidewalls. For making rectangular structures do not advise to measure the same size separately (some reason do). Saw off one, and then impose it on, "strike sharply" grinder, and saws. Accuracy - less than a millimeter with proper accuracy.

We want to make a nice, but not anyhow, right? Take out a piece of the corner to hand welding butt. Places of future welding once we clean. Then it will be too lazy. Whatever wrote about the electrodes "quietly tolerate dirty metal" - better still clean. Welding goes smoothly.

We catch the longitudinal sidewall portions of the chassis 90-degree clamps. Gaugeable diagonally. The diagonals of the same millimeter (and where they are, on the other hand, fuck submarine disappear? ©)

Boil the top and side.

Take a drive and clean the wiper seal flush. We were there once welded legs. Here's what happened. Place welding almost invisible.

We pass around the structure, we clean. Put the leg. Surprisingly, the leg is straight and shows a 90-degree angle. Accuracy sipped decides.

Similarly, with other legs. There will be 6, but here is 4.

We examine the resulting work. It seems ok. Otobaya slag, we'll see.

Six feet. All have turned out exactly, the bottom shelf will give even greater fortress

Slugger slag, look. Well, of course, not the sixth rank, but we for our strength is normal.

Repeat the procedure with the frame, but with a smaller size for the bottom shelf.

More

Welded rack, bringing the legs exactly (and so they are exactly, but look before you leap!). We clean all the seams, we bring down the construction side, welds heels, we clean and hammer enamel already been set (I bought some). The floor of the barn is flat, but the seals, we got gum in any place will, as without them?

Heels dry, lift the structure. Already been set up entirely enamel. Smoke.

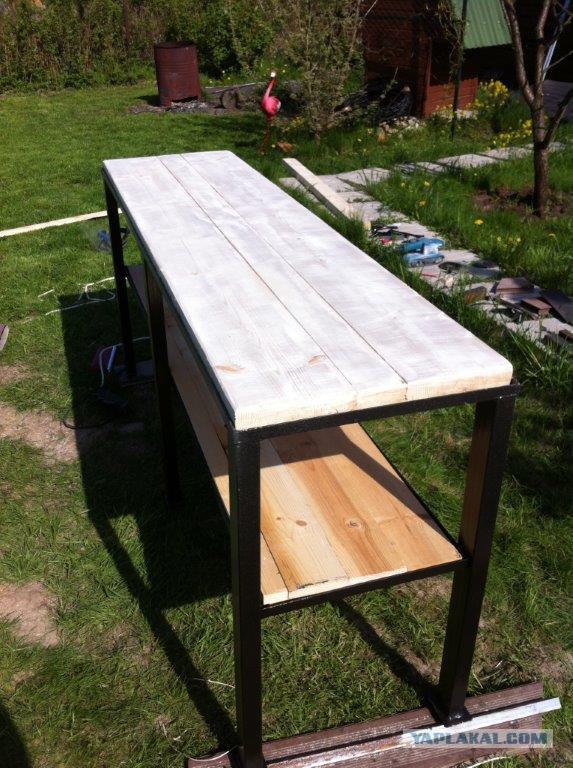

From a different angle. Cool color - black with gold dust. Looks like a powder coating.

Cat I do not have nobody to inspect the work. But! This time crawling fugitive overseas Inspector! The inspector has been raised, examined and given to neighbors. He did not run away from them, but they will give to whom it is necessary, they say they are familiar with the inspector and know him in the face. A small break, we continue.

Let's start from the shelf. Sawing plank polished 120 * 20mm in length. Puts. That damn, do not fit exactly, one would have to dissolve along 5mm. With the monkey is not a problem, two minutes, exactly along the sawn board. Stacking, sew bottom 2 reechkami and screws. Just in case.

Similarly we proceed with unsanded board 200 * 50mm. Again we have to dissolve along. Again dissolved. Let us narrow down the middle. They say love of symmetry - the first sign of schizophrenia. In this frame of reference, I schizophrenic to the bone, even in Plant vs Zombies always put flowers symmetrically.

All are well laid. But the board can not be touched - just a pain. Of course, we grind. Take sander (she just prepared last a photo), and the 60th band roughly grind all the board level, removing large chips and splinters.

Much better, but it is not perfect :)

Take the 120-th tape and again grind to shine. Then grind bluntly does not make sense.

Take in the hands nail brush, we reveal the first layer.

In general, I decided to put three coats of varnish (time allowing). This is the final version. Thank you!

Of course, the purchase workbench - not our method, Shura. We will do ourselves.

Getting.

That's out of this pile of iron, bought the day before, it is necessary to make the Mighty verstachok with a shelf underneath. Sedentary work for the bench is not, so the regiment must be large in size, as full of tools that have nowhere to put, any chisels, gouges, planes and other Gamsakhurdia.

The framework for countertops and shelves - 4mm area. Shelf appears to 25mm.

Feet - 60 * 2mm proftruba 40

Heel - 2 mm sheet metal.

Will be 24 photos.

Smoke break, kofeek, removal tool.

For all the work we need:

1. The Bulgarian (preferably two - cleaned and cut).

2. The welding machine electrodes + + + mask slag hammer + brush + leggings + welding robe

3. Corner + pencil + roulette

4. Clamps and conventional 90-degree

5. The mask stripper joints

6. Grind + 60 and 120 tapes

7. Hand Circular Saw

8. + Nail brush

We start with a framework for countertops. Saw off corner sidewalls. For making rectangular structures do not advise to measure the same size separately (some reason do). Saw off one, and then impose it on, "strike sharply" grinder, and saws. Accuracy - less than a millimeter with proper accuracy.

We want to make a nice, but not anyhow, right? Take out a piece of the corner to hand welding butt. Places of future welding once we clean. Then it will be too lazy. Whatever wrote about the electrodes "quietly tolerate dirty metal" - better still clean. Welding goes smoothly.

We catch the longitudinal sidewall portions of the chassis 90-degree clamps. Gaugeable diagonally. The diagonals of the same millimeter (and where they are, on the other hand, fuck submarine disappear? ©)

Boil the top and side.

Take a drive and clean the wiper seal flush. We were there once welded legs. Here's what happened. Place welding almost invisible.

We pass around the structure, we clean. Put the leg. Surprisingly, the leg is straight and shows a 90-degree angle. Accuracy sipped decides.

Similarly, with other legs. There will be 6, but here is 4.

We examine the resulting work. It seems ok. Otobaya slag, we'll see.

Six feet. All have turned out exactly, the bottom shelf will give even greater fortress

Slugger slag, look. Well, of course, not the sixth rank, but we for our strength is normal.

Repeat the procedure with the frame, but with a smaller size for the bottom shelf.

More

Welded rack, bringing the legs exactly (and so they are exactly, but look before you leap!). We clean all the seams, we bring down the construction side, welds heels, we clean and hammer enamel already been set (I bought some). The floor of the barn is flat, but the seals, we got gum in any place will, as without them?

Heels dry, lift the structure. Already been set up entirely enamel. Smoke.

From a different angle. Cool color - black with gold dust. Looks like a powder coating.

Cat I do not have nobody to inspect the work. But! This time crawling fugitive overseas Inspector! The inspector has been raised, examined and given to neighbors. He did not run away from them, but they will give to whom it is necessary, they say they are familiar with the inspector and know him in the face. A small break, we continue.

Let's start from the shelf. Sawing plank polished 120 * 20mm in length. Puts. That damn, do not fit exactly, one would have to dissolve along 5mm. With the monkey is not a problem, two minutes, exactly along the sawn board. Stacking, sew bottom 2 reechkami and screws. Just in case.

Similarly we proceed with unsanded board 200 * 50mm. Again we have to dissolve along. Again dissolved. Let us narrow down the middle. They say love of symmetry - the first sign of schizophrenia. In this frame of reference, I schizophrenic to the bone, even in Plant vs Zombies always put flowers symmetrically.

All are well laid. But the board can not be touched - just a pain. Of course, we grind. Take sander (she just prepared last a photo), and the 60th band roughly grind all the board level, removing large chips and splinters.

Much better, but it is not perfect :)

Take the 120-th tape and again grind to shine. Then grind bluntly does not make sense.

Take in the hands nail brush, we reveal the first layer.

In general, I decided to put three coats of varnish (time allowing). This is the final version. Thank you!