792

How do nuclear fuel (29 photos)

Novosibirsk Chemical Concentrates Plant in 2011, produced and sold 70% of world consumption of the isotope lithium-7 (1300 kg), a new record in the history of the plant. However, the main product of the production of nuclear fuel is the NCCP.

This phrase affects the consciousness of Novosibirsk impressive and intimidating, causing the company to imagine anything: from the three-legged individual workers and the underground city and ending with radioactive wind.

So what really lies behind the fences of the most mysterious of Novosibirsk plant producing nuclear fuel in the city?

JSC "Novosibirsk Chemical Concentrates Plant" - one of the world's leading producers of nuclear fuel for nuclear power plants and research reactors in Russia and abroad. The only Russian manufacturer of lithium metal and its salts. Included in the Fuel Company "TVEL" State Corporation "Rosatom».

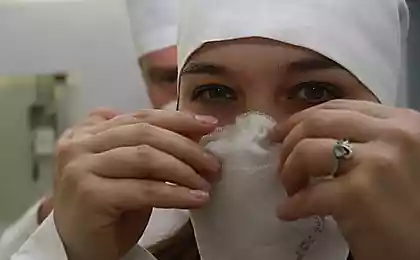

We came to the shop, where fuel assemblies are produced - fuel assemblies are loaded in nuclear power reactors. This is nuclear fuel. To enter the production need to wear gowns, caps, shoe covers made of cloth, on the face - "Petal».

The workshop focused all work related to uranium-bearing materials. This technological complex is one of the key for the NCCP (fuel assemblies for nuclear power plants take up about 50% of the sales of "NPCC»)

Operator, where is management of the production of uranium dioxide powder, which is then manufactured fuel pellets.

Work carried out maintenance work: after a certain period of time, even the newest equipment was stopped and checked. In the shop are always a lot of air - constantly running exhaust ventilation.

In such bicones stored uranium dioxide powder. They are the mixing of the powder and a plasticizer, which allows the tablet to better compacted.

The plant, which produces compression of fuel pellets. As children make sand kulichiki, pushing the mold, and here: uranium pellets compressed under pressure.

Molybdenum boat with tablets that are waiting for departure in the oven for a joke. Before annealing tablets have a greenish tint and other size.

Contact a powder, tablet, and the environment is minimized: all the work carried out in the pits. In order to correct something inside the boxes are built special gloves.

Torches on top - it's the dying hydrogen. Tablets are annealed in an oven at a temperature of not less than 1750 ° in a hydrogen reducing atmosphere for more than 20 hours.

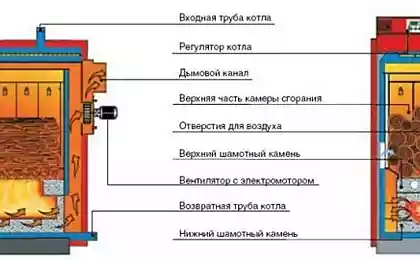

Black cabinets - a high-temperature hydrogen furnace, in which a molybdenum boat goes through various temperature zones. Opens the shutter, and into the oven, where the flames erupt, comes molybdenum boat.

Finished tablets are polished as they should be strictly specified size. And the output inspectors check every pill that had no chips, no cracks, no defects.

One tablet weighing 4, 5 g of energy release is equivalent to 640 kg of wood, 400 kg of coal, 360 cubic meters. meters of gas, 350 kg of oil.

Tablets uranium dioxide after annealing in a hydrogen furnace.

There zirconium tubes filled with uranium dioxide pellets. At the output of the fuel rods have finished (about 4 m long) - the fuel elements. Because of the fuel elements already collected FA, in other words, nuclear fuel.

Such machines with soda on the streets do not meet, perhaps, only in the NCCP. While in Soviet times, they were very common.

This machine can wash the glass and then fill carbonated, non-carbonated water or chilled.

According to the Department of Natural Resources and Environment, expressed in 2010, the NCCP has no significant effect on pollution.

Couple of purebred chicken constantly lives and lays its eggs in a good wooden enclosure, which is on the territory of the plant.

Workers welded frame for a fuel assembly. Frameworks are different, depending on the version of TVS.

As of 1 January 2012, the factory work in 2277, and the average age of the personnel - 44, 3 years, 58% - men. The average wage exceeds 38,000 rubles.

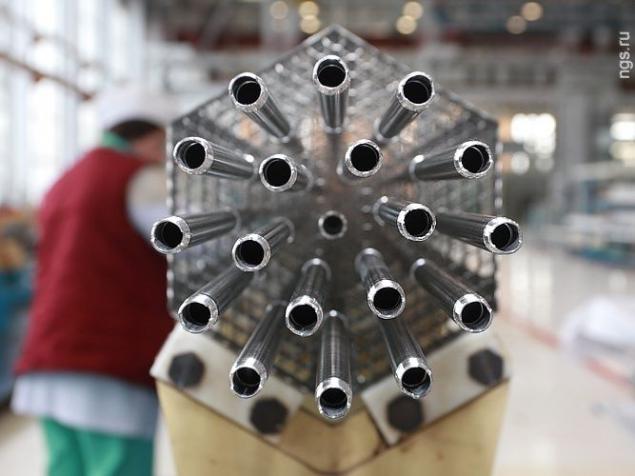

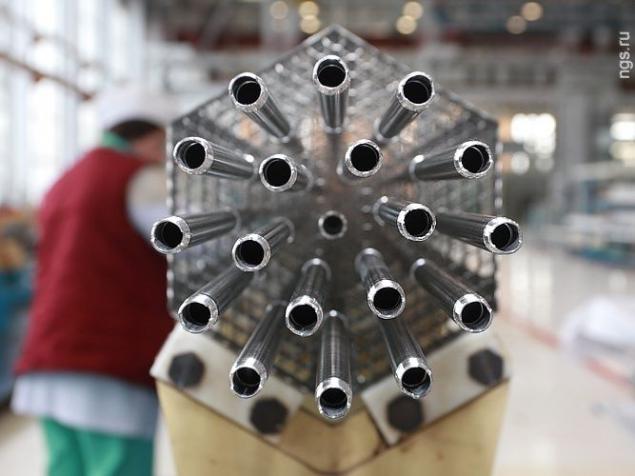

Large tube - a control channel for the reactor protection system. In this framework then install 312 fuel rods.

Adjacent to the NCCP located CHP-4. With reference to the representatives of the plant ecologists reported: one year CHP emits radioactive substances into the 7, 5 times more than the NCCP.

Fitter Victor Pustozerov, a veteran of the plant and the nuclear power industry, has 2 of the Order of Labour Glory.

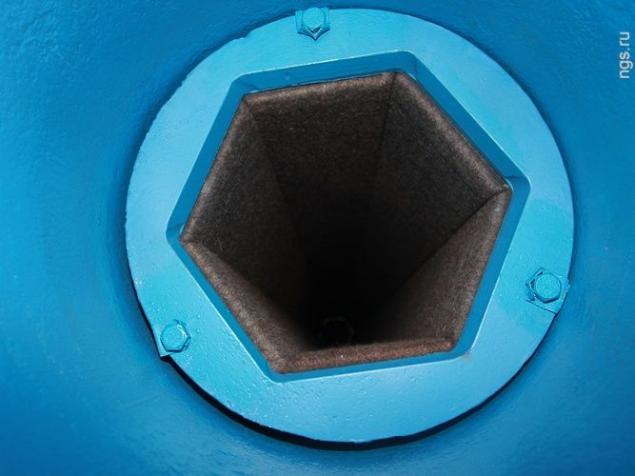

The head and shaft for TVS. They are placed at the very end, when the frame is already worth all the 312 fuel rods.

Final inspection: check the finished fuel assemblies with special probes to the distance between the fuel rods were the same. Supervisors often women, it is very hard work.

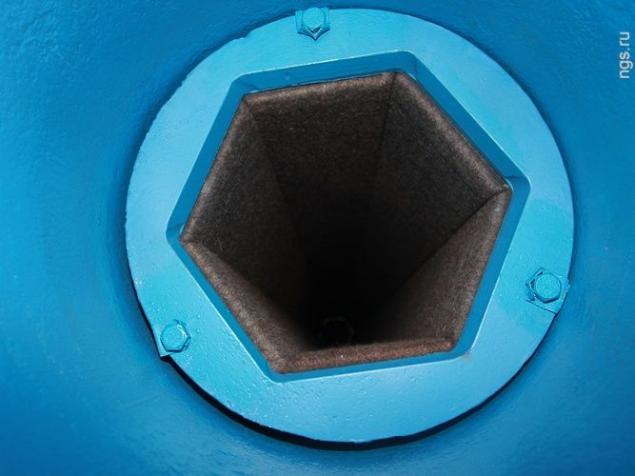

In such fuel assemblies are sent to the consumer containers - 2 in each cassette. Inside they have their own cozy bed Felt.

Fuel for nuclear power stations produced by JSC "NCCP", used in Russian nuclear power plants and supplied to Ukraine, Bulgaria, China, India and Iran. The cost of fuel assemblies is a commercial secret.

Work at NCCP no hazardous work in any industrial undertaking. Workers' health is being monitored constantly. In recent years, did not reveal a single case of occupational diseases among workers.

This phrase affects the consciousness of Novosibirsk impressive and intimidating, causing the company to imagine anything: from the three-legged individual workers and the underground city and ending with radioactive wind.

So what really lies behind the fences of the most mysterious of Novosibirsk plant producing nuclear fuel in the city?

JSC "Novosibirsk Chemical Concentrates Plant" - one of the world's leading producers of nuclear fuel for nuclear power plants and research reactors in Russia and abroad. The only Russian manufacturer of lithium metal and its salts. Included in the Fuel Company "TVEL" State Corporation "Rosatom».

We came to the shop, where fuel assemblies are produced - fuel assemblies are loaded in nuclear power reactors. This is nuclear fuel. To enter the production need to wear gowns, caps, shoe covers made of cloth, on the face - "Petal».

The workshop focused all work related to uranium-bearing materials. This technological complex is one of the key for the NCCP (fuel assemblies for nuclear power plants take up about 50% of the sales of "NPCC»)

Operator, where is management of the production of uranium dioxide powder, which is then manufactured fuel pellets.

Work carried out maintenance work: after a certain period of time, even the newest equipment was stopped and checked. In the shop are always a lot of air - constantly running exhaust ventilation.

In such bicones stored uranium dioxide powder. They are the mixing of the powder and a plasticizer, which allows the tablet to better compacted.

The plant, which produces compression of fuel pellets. As children make sand kulichiki, pushing the mold, and here: uranium pellets compressed under pressure.

Molybdenum boat with tablets that are waiting for departure in the oven for a joke. Before annealing tablets have a greenish tint and other size.

Contact a powder, tablet, and the environment is minimized: all the work carried out in the pits. In order to correct something inside the boxes are built special gloves.

Torches on top - it's the dying hydrogen. Tablets are annealed in an oven at a temperature of not less than 1750 ° in a hydrogen reducing atmosphere for more than 20 hours.

Black cabinets - a high-temperature hydrogen furnace, in which a molybdenum boat goes through various temperature zones. Opens the shutter, and into the oven, where the flames erupt, comes molybdenum boat.

Finished tablets are polished as they should be strictly specified size. And the output inspectors check every pill that had no chips, no cracks, no defects.

One tablet weighing 4, 5 g of energy release is equivalent to 640 kg of wood, 400 kg of coal, 360 cubic meters. meters of gas, 350 kg of oil.

Tablets uranium dioxide after annealing in a hydrogen furnace.

There zirconium tubes filled with uranium dioxide pellets. At the output of the fuel rods have finished (about 4 m long) - the fuel elements. Because of the fuel elements already collected FA, in other words, nuclear fuel.

Such machines with soda on the streets do not meet, perhaps, only in the NCCP. While in Soviet times, they were very common.

This machine can wash the glass and then fill carbonated, non-carbonated water or chilled.

According to the Department of Natural Resources and Environment, expressed in 2010, the NCCP has no significant effect on pollution.

Couple of purebred chicken constantly lives and lays its eggs in a good wooden enclosure, which is on the territory of the plant.

Workers welded frame for a fuel assembly. Frameworks are different, depending on the version of TVS.

As of 1 January 2012, the factory work in 2277, and the average age of the personnel - 44, 3 years, 58% - men. The average wage exceeds 38,000 rubles.

Large tube - a control channel for the reactor protection system. In this framework then install 312 fuel rods.

Adjacent to the NCCP located CHP-4. With reference to the representatives of the plant ecologists reported: one year CHP emits radioactive substances into the 7, 5 times more than the NCCP.

Fitter Victor Pustozerov, a veteran of the plant and the nuclear power industry, has 2 of the Order of Labour Glory.

The head and shaft for TVS. They are placed at the very end, when the frame is already worth all the 312 fuel rods.

Final inspection: check the finished fuel assemblies with special probes to the distance between the fuel rods were the same. Supervisors often women, it is very hard work.

In such fuel assemblies are sent to the consumer containers - 2 in each cassette. Inside they have their own cozy bed Felt.

Fuel for nuclear power stations produced by JSC "NCCP", used in Russian nuclear power plants and supplied to Ukraine, Bulgaria, China, India and Iran. The cost of fuel assemblies is a commercial secret.

Work at NCCP no hazardous work in any industrial undertaking. Workers' health is being monitored constantly. In recent years, did not reveal a single case of occupational diseases among workers.