1255

How to make the monuments and sculptures

The author visited two production workshops and learned how things work.

The company specializes in monumental art castings of bronze, aluminum and cast iron.

Yet here make plaster sculptures of all sizes.

Let's go.

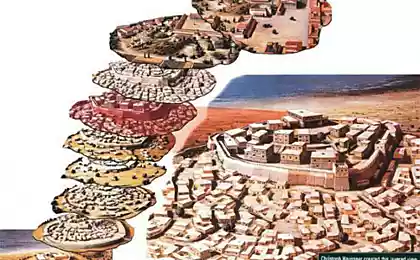

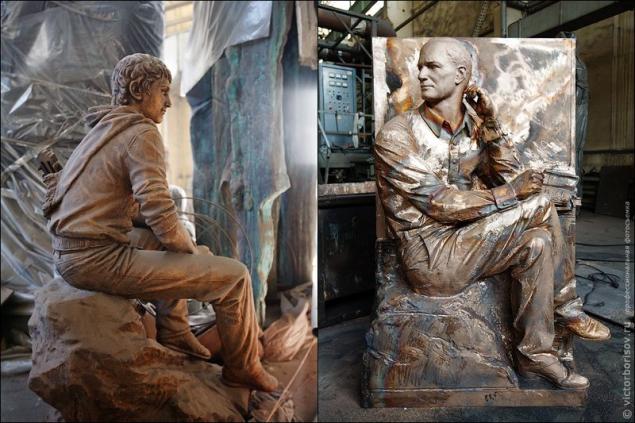

1. First, make a full-size gypsum model of the future monument.

2. Sometimes monuments make entirely of plaster, to do this, first create a copy of the scale on which are marked control points.

3. Then, the control points welded main frame.

4. Which later obkladyvaetsya plaster, while the sculpture is hollow inside.

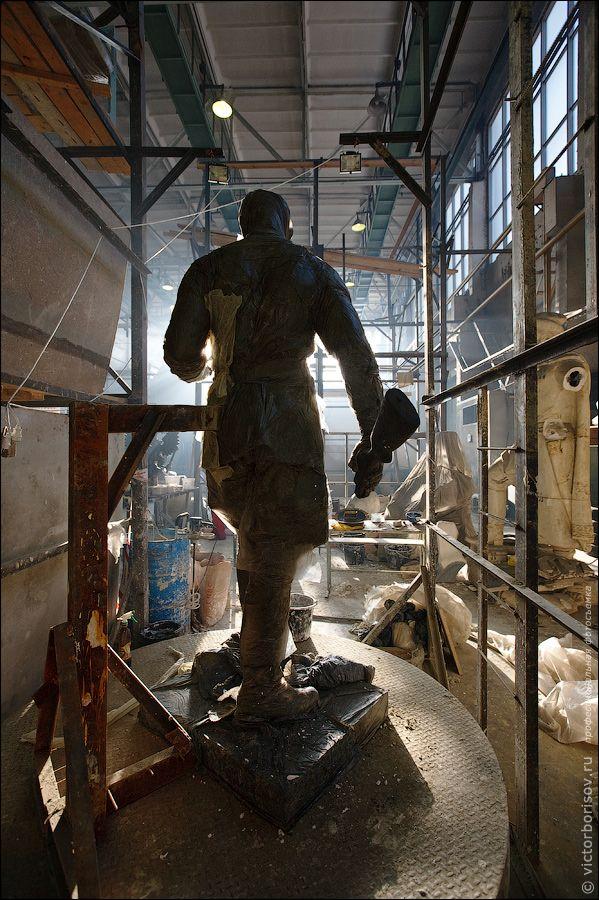

5. The monument is made of this model can be seen in the end of the report.

6. It is still in operation. He wrapped the film after the primary giving overall shape.

7. Go to the shop of art casting. There is much more interesting.

8. With a working model made of clay or gypsum plaster mold is removed lumps. According to information received form made wax models of separate parts of the sculpture.

9. The wax model is placed in the plaster mold, where they cool. The wax model cooled stuffed core mold of the cold-hardening mixture (CTS), which is composed of resin and sand. Exterior plaster mold is opened, and the author of the wax can make the necessary improvements to make the model of the future cast a working model of compliance.

10. lump form of cold-hardening mixture disassembled. The wax is removed manually with rod form of CTD and not melted in the furnace. The inner surface of the parsed form of paint is covered with non-stick, which can be of two kinds: one - for the most accurate casting small pieces of fabric, and the second - to obtain a perfectly smooth surface of the product. In the cavity from which the wax has been removed, the molten metal is poured.

11. Preparation of the cold-hardening mixture (CTS).

12. Workflow.

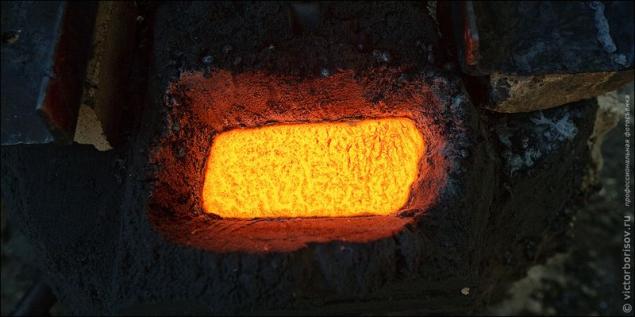

13. All blanks are moved into the shop floor via electric winches. Already started kindling furnace.

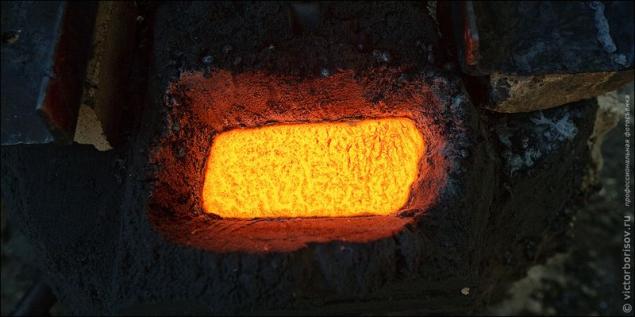

14. In bringing one full tank in the furnace to the condition it takes about 10 minutes.

15. Pour the molten metal from the boiler and remove the "scum».

16. Pour into a pre-prepared form.

17. In the meantime, is preparing a second vat of metal look around - away shop finishing with bronze blanks.

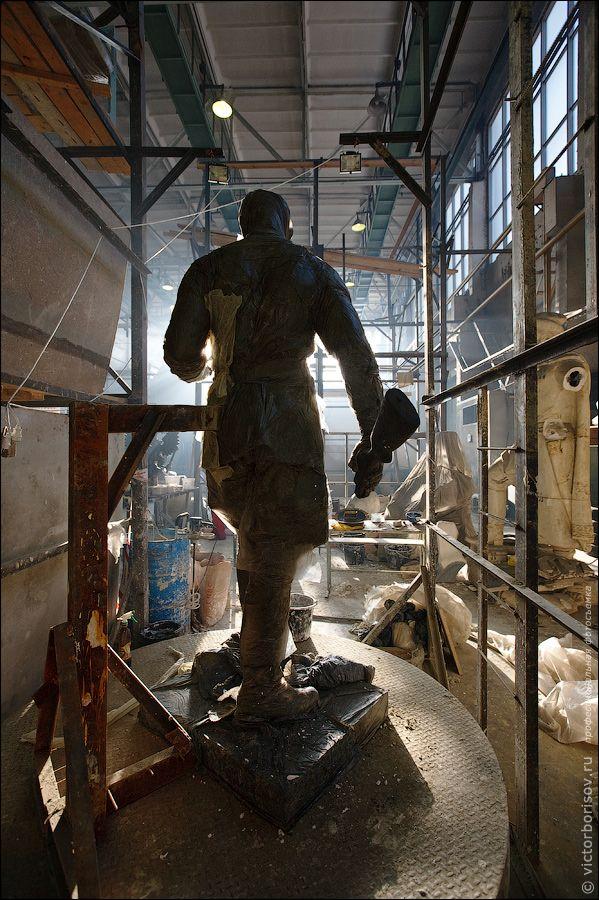

18. Repeat the process.

19. Fill.

20. Warmly !!!

21. We reserve the metal to solidify.

22. A pour excess back into the oven.

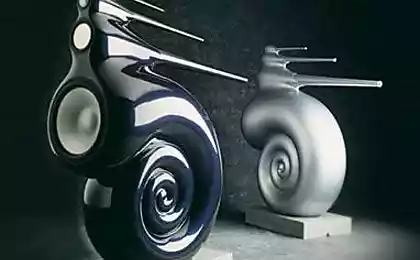

23. After the molded parts zastynut they should be collected in a solid monument. This is done using gas welding.

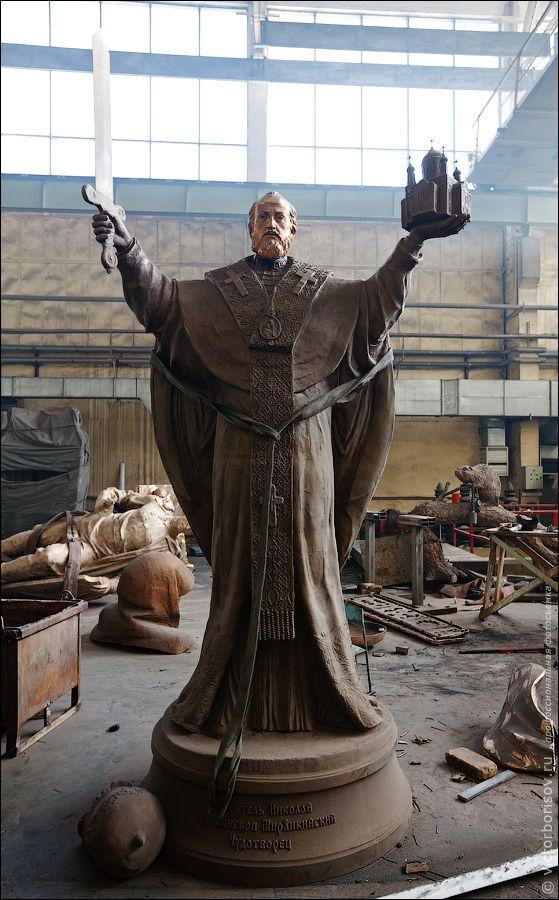

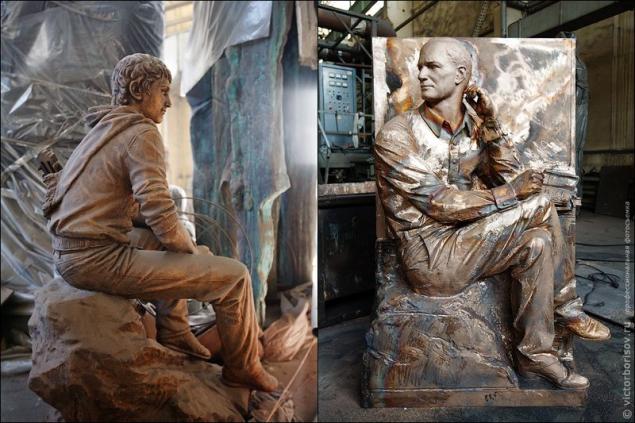

24. The Working scale model.

25. And it is finished monument.

26. Somewhere saw off somewhere welded - and then all of this grind.

27. Welding.

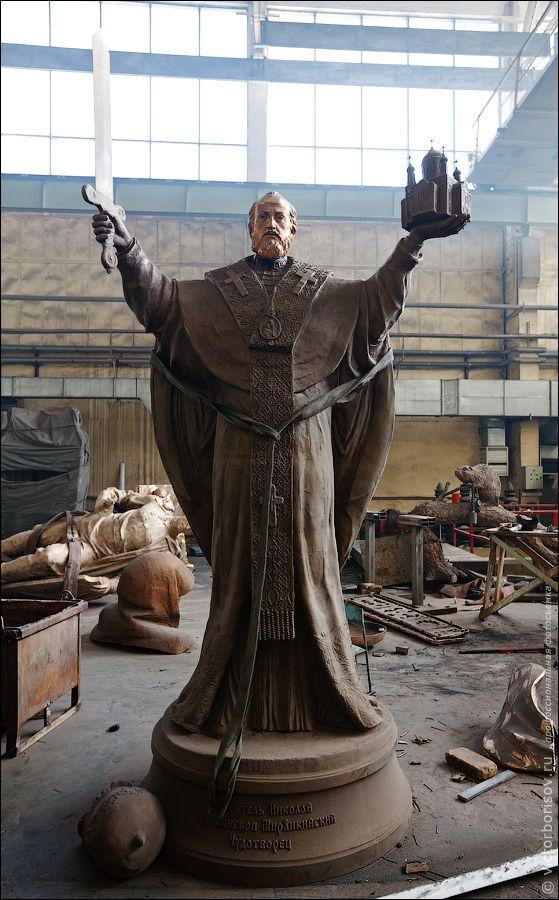

28. The result is here such monuments.

29. The work quite laborious, but very impressive.

Source: victorprofessor.livejournal.com

The company specializes in monumental art castings of bronze, aluminum and cast iron.

Yet here make plaster sculptures of all sizes.

Let's go.

1. First, make a full-size gypsum model of the future monument.

2. Sometimes monuments make entirely of plaster, to do this, first create a copy of the scale on which are marked control points.

3. Then, the control points welded main frame.

4. Which later obkladyvaetsya plaster, while the sculpture is hollow inside.

5. The monument is made of this model can be seen in the end of the report.

6. It is still in operation. He wrapped the film after the primary giving overall shape.

7. Go to the shop of art casting. There is much more interesting.

8. With a working model made of clay or gypsum plaster mold is removed lumps. According to information received form made wax models of separate parts of the sculpture.

9. The wax model is placed in the plaster mold, where they cool. The wax model cooled stuffed core mold of the cold-hardening mixture (CTS), which is composed of resin and sand. Exterior plaster mold is opened, and the author of the wax can make the necessary improvements to make the model of the future cast a working model of compliance.

10. lump form of cold-hardening mixture disassembled. The wax is removed manually with rod form of CTD and not melted in the furnace. The inner surface of the parsed form of paint is covered with non-stick, which can be of two kinds: one - for the most accurate casting small pieces of fabric, and the second - to obtain a perfectly smooth surface of the product. In the cavity from which the wax has been removed, the molten metal is poured.

11. Preparation of the cold-hardening mixture (CTS).

12. Workflow.

13. All blanks are moved into the shop floor via electric winches. Already started kindling furnace.

14. In bringing one full tank in the furnace to the condition it takes about 10 minutes.

15. Pour the molten metal from the boiler and remove the "scum».

16. Pour into a pre-prepared form.

17. In the meantime, is preparing a second vat of metal look around - away shop finishing with bronze blanks.

18. Repeat the process.

19. Fill.

20. Warmly !!!

21. We reserve the metal to solidify.

22. A pour excess back into the oven.

23. After the molded parts zastynut they should be collected in a solid monument. This is done using gas welding.

24. The Working scale model.

25. And it is finished monument.

26. Somewhere saw off somewhere welded - and then all of this grind.

27. Welding.

28. The result is here such monuments.

29. The work quite laborious, but very impressive.

Source: victorprofessor.livejournal.com