721

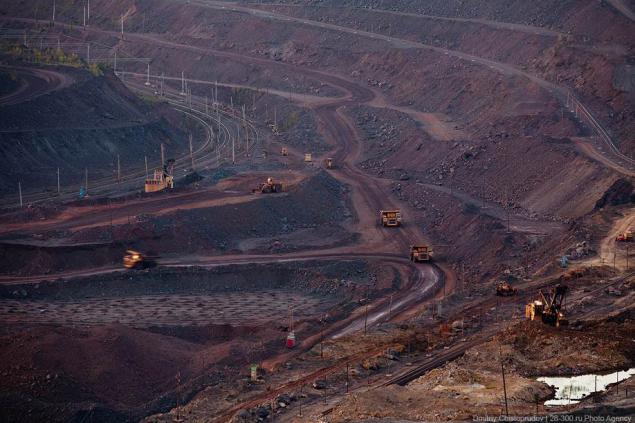

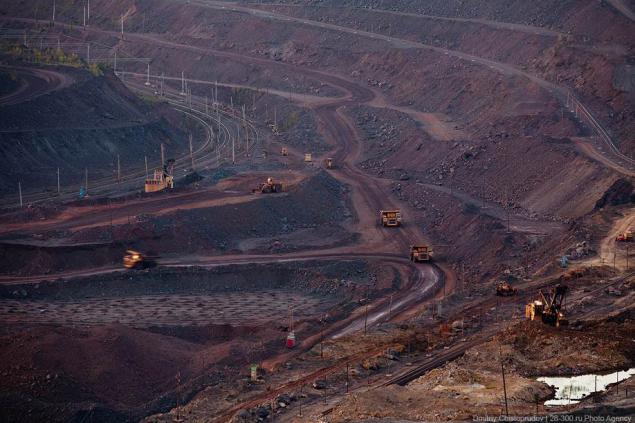

Dawn on the career of Mikhailovsky GOK

Kursk Magnetic Anomaly (KMA) - the most powerful in the world iron ore basin. Its deposits are estimated at 200-210 billion. Tons, accounting for about 50% of iron ore reserves on the planet. Mikhailovsky deposit is part of the Kursk-Oryol iron ore district, located in the western part of the Kursk and Orel regions.

32 Photo © Dmitry Chistoprudov

1. Currently, the border stretch of iron ore deposits KMA covers an area of over 160 thousand sq. Km, capturing the territory of the nine areas of the Center and South of the country.

2. Mikhailovsky ore mining deposits comes in three pits (South, Central and North) with a total length of about 6 km and a width of about 4 km. The volume of proven ore reserves of the deposits of more than $ 11 billion. Tons, which is sufficient for the company entered on the capacity for over 300 years.

3. In 1923, at a depth of 167 meters were produced the first samples of iron ores. In 1950 it was opened Mikhailovsky iron ore deposit, and seven years later, it was decided the Council of Ministers to start construction of a mining facility for the extraction of ore.

4. Soon in his career held its first stripping and in 1960 was produced first bucket of high-grade iron ore. Development of loose overburden rocks in a quarry plant being draglines of the "dragline" ESH 10/50. Overburden loose material transported by rail to external dumps and partially to the factories for the production of building materials.

5. In October 1967, began the construction of mining and processing complex, and in October 1973 received the first iron ore concentrate. The raw material base of the plant - unique in scale and quality of the reserves of ferruginous quartzites.

6. At night work does not stop for a minute and maintained at the same rate as during the day. Night bat like a whole city, a stunning sight!

7. Extraction of ore by open way by means of blasting, excavation and transportation of mined rock by road and rail.

8. Along the way, non-metallic mineral raw materials - sand, chalk, crystalline schists, quartzitic sandstone are mined by an internal railway transport is shipped to consumers.

9. Also, using rail transport is made unnecessary transportation of rock and loose rock on special dumps.

10. Testing of the rock mass (removal of her career) precedes the explosive training carried out with the aim of loosening of the rock mass. Drilling of blast holes is performed by special drilling rigs. The wells are filled with charge and explode the chain. For 1-2 seconds in turn explodes several dozen wells. If you blow up all at the same time, the force of the detonation would be comparable to an earthquake. Blasting is performed as a regular explosives (TNT, ammonium, and others.) And granemitom own making. In the picture you can see a small pile of rocks - a place of laying the explosives.

11. Testing of ferruginous quartzite and rock made huge excavators of the "shovel". Bucket capacity of the excavator is 10 cubic meters, or the body of one of KAMAZ.

12.

13. Operating weight of such machines about 400 tons, and height (with boom box head) almost five-story building. The crawler chassis allows you to move on slopes up to 12 degrees. If working off passes near the railroad tracks, excavators and rock ore is loaded directly into wagons.

14. In the case before the railway far, the ore is first loaded into dump trucks and then transferred to a rail on special transfer points in his career.

15. Excavator-type "dragline" bucket that is suspended on cables, have the greatest radius of digging, almost 100 meters, which is five times more than the excavators "mechanical shovel."

16. Transportation of ore to the processing plant and the loose rock overburden dumps is made on special trains. At the head of the composition is OPE1 traction units, which is specially designed to work on the railways and open cast mining is able to pull out of a career laden Railroad dump cars (freight cars for transportation and automated unloading of the overburden). The mill trains are called "decks" for tipping for unloading the car body. Weight dumpcar about 150 tons and the weight of about 25. To provide the necessary strength of the floor stand is made multilayered, it is composed of a frame laid on the lower steel sheet, a cushioning layer and upper sheet package.

17. Because of the gradual development of career railways often have to be dismantled and re-transfer. Since the "pinwheel" run on electricity, all the way has to be electrified.

18. Drilling rigs, excavators, huge dump trucks, bulldozers, trains, at a depth of 300 meters seem toy.

19. Close the machines are huge! For example at this BELAZ engine 1600 hp! All his power he gives no mechanical transmission, and alternator, which in turn feeds the traction motors. On the 100 kilometers of the elephant consumes about 200 liters of diesel fuel.

20.

21. Over 25% of mine production is exported. Major countries - Ukraine, Czech Republic, Slovakia and Romania.

22.

23.

24. The morning shift change truck drivers. I also had to spend the night right on the viewing platform of the GOK in the car, because it is the only hotel in the city in the morning took thirty for some new tourists, and I have not had the patience to wait for them all register.

25. Quarry at dawn - a fascinating spectacle. To go down to their place of work may need to walk up to six hours.

26. The process of drilling wells.

27.

28.

29. Prior to the jobs of employees carried about on the buses, and if there's no hurry, you can walk.

30. To date, Mikhailovsky GOK produces about 20% of domestic iron ore, accounting for 25% of total Russian production of pellets.

31.

32. Mikhailovsky GOK - the only one of the big quarries KMA, which has a viewing platform, the clock open to all comers. This is the view from this point.

33

Source:

32 Photo © Dmitry Chistoprudov

1. Currently, the border stretch of iron ore deposits KMA covers an area of over 160 thousand sq. Km, capturing the territory of the nine areas of the Center and South of the country.

2. Mikhailovsky ore mining deposits comes in three pits (South, Central and North) with a total length of about 6 km and a width of about 4 km. The volume of proven ore reserves of the deposits of more than $ 11 billion. Tons, which is sufficient for the company entered on the capacity for over 300 years.

3. In 1923, at a depth of 167 meters were produced the first samples of iron ores. In 1950 it was opened Mikhailovsky iron ore deposit, and seven years later, it was decided the Council of Ministers to start construction of a mining facility for the extraction of ore.

4. Soon in his career held its first stripping and in 1960 was produced first bucket of high-grade iron ore. Development of loose overburden rocks in a quarry plant being draglines of the "dragline" ESH 10/50. Overburden loose material transported by rail to external dumps and partially to the factories for the production of building materials.

5. In October 1967, began the construction of mining and processing complex, and in October 1973 received the first iron ore concentrate. The raw material base of the plant - unique in scale and quality of the reserves of ferruginous quartzites.

6. At night work does not stop for a minute and maintained at the same rate as during the day. Night bat like a whole city, a stunning sight!

7. Extraction of ore by open way by means of blasting, excavation and transportation of mined rock by road and rail.

8. Along the way, non-metallic mineral raw materials - sand, chalk, crystalline schists, quartzitic sandstone are mined by an internal railway transport is shipped to consumers.

9. Also, using rail transport is made unnecessary transportation of rock and loose rock on special dumps.

10. Testing of the rock mass (removal of her career) precedes the explosive training carried out with the aim of loosening of the rock mass. Drilling of blast holes is performed by special drilling rigs. The wells are filled with charge and explode the chain. For 1-2 seconds in turn explodes several dozen wells. If you blow up all at the same time, the force of the detonation would be comparable to an earthquake. Blasting is performed as a regular explosives (TNT, ammonium, and others.) And granemitom own making. In the picture you can see a small pile of rocks - a place of laying the explosives.

11. Testing of ferruginous quartzite and rock made huge excavators of the "shovel". Bucket capacity of the excavator is 10 cubic meters, or the body of one of KAMAZ.

12.

13. Operating weight of such machines about 400 tons, and height (with boom box head) almost five-story building. The crawler chassis allows you to move on slopes up to 12 degrees. If working off passes near the railroad tracks, excavators and rock ore is loaded directly into wagons.

14. In the case before the railway far, the ore is first loaded into dump trucks and then transferred to a rail on special transfer points in his career.

15. Excavator-type "dragline" bucket that is suspended on cables, have the greatest radius of digging, almost 100 meters, which is five times more than the excavators "mechanical shovel."

16. Transportation of ore to the processing plant and the loose rock overburden dumps is made on special trains. At the head of the composition is OPE1 traction units, which is specially designed to work on the railways and open cast mining is able to pull out of a career laden Railroad dump cars (freight cars for transportation and automated unloading of the overburden). The mill trains are called "decks" for tipping for unloading the car body. Weight dumpcar about 150 tons and the weight of about 25. To provide the necessary strength of the floor stand is made multilayered, it is composed of a frame laid on the lower steel sheet, a cushioning layer and upper sheet package.

17. Because of the gradual development of career railways often have to be dismantled and re-transfer. Since the "pinwheel" run on electricity, all the way has to be electrified.

18. Drilling rigs, excavators, huge dump trucks, bulldozers, trains, at a depth of 300 meters seem toy.

19. Close the machines are huge! For example at this BELAZ engine 1600 hp! All his power he gives no mechanical transmission, and alternator, which in turn feeds the traction motors. On the 100 kilometers of the elephant consumes about 200 liters of diesel fuel.

20.

21. Over 25% of mine production is exported. Major countries - Ukraine, Czech Republic, Slovakia and Romania.

22.

23.

24. The morning shift change truck drivers. I also had to spend the night right on the viewing platform of the GOK in the car, because it is the only hotel in the city in the morning took thirty for some new tourists, and I have not had the patience to wait for them all register.

25. Quarry at dawn - a fascinating spectacle. To go down to their place of work may need to walk up to six hours.

26. The process of drilling wells.

27.

28.

29. Prior to the jobs of employees carried about on the buses, and if there's no hurry, you can walk.

30. To date, Mikhailovsky GOK produces about 20% of domestic iron ore, accounting for 25% of total Russian production of pellets.

31.

32. Mikhailovsky GOK - the only one of the big quarries KMA, which has a viewing platform, the clock open to all comers. This is the view from this point.

33

Source: