948

From the Life of Amber Factory

About 50 million years ago the world was a significant warming of the climate and as a result, excessive smoloistechenie trees in coniferous forests of Scandinavia. The resin is oxidized by atmospheric oxygen and accumulates in the soil "amber forests". Rivers and streams are gradually washed out of the resin hardened lumps of earth and demolished them in the mouth of a large river flowing into the ancient sea in what is now Kaliningrad peninsula. Thus was formed the world's largest deposit of amber - Seaside or Palmnikenskoe. It is unrivaled not only in proven reserves, but also on the concentration of gem. Here, amber is found in the so-called blue earth - sand-clay rocks of marine origin, widespread in the territory of the Kaliningrad peninsula.

Since ancient times, the Baltic amber collected on the beaches and shallows, where he threw out the sea and used for medicinal, religious, artistic and applied purposes. Over the last three thousand years the Baltic Sea has been collected about 60 thousand tons of the mineral. Since the XVI century on the beaches became popular new method of extraction of amber - fishing. Hunters armed with large nets, 6-8-meter poles went into the water and out to sea in a boat and caught with seaweed tangled in them amber.

31 phot via victorprofessor

For the first time to produce amber land way began in the middle of the XVI century. On the shore of digging holes and, if the ground turned out to be a grain of amber, on the bottom hoed until groundwater. On the surface surfaced pieces of amber. In the middle of the XVII century, attempts were made to dig amber from coastal cliffs. And already in 1871 it was laid the first pit depth of about 30 meters with a view to commercial production of amber near today's village of Sinyavino.

It turned out to be more productive extraction via open-pit mines in the first half of the XIX century. In the richer parts of the coast were laid amber small pits (30 x 30 meters). Layers gangue frustrated and autopsied layer "blue earth", which was developed. But by the beginning of the XX century, underground mining became unprofitable. And in 1912, at a distance from the sea, for the open development of the field, it was laid a large mine, operated for about 60 years, will run out in the early 70s.

Before World War II Palmnikenskom deposit was mined for about 400 tons of raw amber a year: about half of them processed at Koenigsberg Amber Manufactory, which included several factories and workshops in various locations in Eastern Prussia. At the end of 1930 on the amber enterprises Palmniken and Koenigsberg was occupied by more than 2, 5 thousand employees. The same number of workers, mostly women, were hired to support the work in the winter.

When in 1945 the Russian army liberator came to the land of East Prussia, it was quite obvious that the Germans have ceased production of amber before their arrival. Amber quarry was flooded and more like a dead lake yellow.

Mining company functioned under the Germans, it was decided to revive. In warehouses Palmniken after the retreat of German forces left several dozen tons of first-class amber. Thanks to these reserves were organizovanynebolshie workshops, which employ demobilized Soviet soldiers and the rest in the village of German residents. Later workshops were transformed into amber factory in the Voentorg, which were made necklaces, bangles, mouthpieces and souvenirs made of amber, insulators for geological exploration equipment ores of uranium and radium. So there was the first post-war amber products plant.

In 1947, Amber Plant visited a government commission headed by AN Kosygin, who had come to the conclusion about the necessity of its transfer to the Ministry of the Interior, has qualified personnel and experience in the organization of work in the extractive industries. 21 July 1947 the Council of Ministers adopted a decree number 2599 on the transfer of production of amber along with career in the Ministry of Interior of the USSR. The new company was given the name "The plant number 9". Education kombinatane entailed the elimination Yantarnogozavoda trust "Russian gems". The factory was moved to the village of Primorye near Svetlogorsk and tourist center located in the building of "Anchor". In fact, it was one shop, where in the early 50th hgodov labor is not more than 120 people. Raw plant received from the plant number 9, the range of products remained not too rich.

In the fall of 1947 began pumping water from the pit into the sea, from the bottom of the rock was removed, restored the site. At the same time carried out the reconstruction of access roads and repair of the equipment survived. In June 1948, the quarry was put into commercial operation until the end of the year it was produced 115,897 kg of amber raw.

In 1953, the Amber plant was transferred from the Ministry of Internal Affairs of trust "Russian gems" at the same time there was a unification of the plant and the plant. The new management of the plant was formed from the experts sent from Leningrad headed by the first civilian director of the KP Polyakov, who was soon replaced as KN Rizaev. For the efficient operation of the company it was necessary, first of all, to resume commercial production of amber. Steady work career hampered by a lack of equipment and spare parts, lack of qualified specialists. The situation was corrected after in October 1955, this critical section headed VN Rozhkov, an experienced engineer miner. But the possibilities pledged at the beginning of the century career largely been exhausted. Areas with the highest content of Ba amber were successively developed, and the southern part of the most promising deposits remained virtually inaccessible to production due to frequent landslides of soil.

The process of extraction and purification of amber while very different from how it is today. During the first decade after the launch of the plant was designed only quarry excavation method. Overburden of railroad went to the dump, and containing amber "blue earth" on trains delivered for initial processing. The results of a career in the 50s were not high enough. In the year extracted, on average, 240 tons of amber, dominated by his fines, while demand continued to grow Baltic gem.

It was necessary to make a radical renewal of the entire production technology. The push to the top of the reconstruction gave the element. 7 November 1957 and 10 February 1958, one after another, there were two disaster - large landslides of soil, resulting in the bottom of the quarry has fallen more than half a million tons of earth. Failure were excluded almost all of the transport system, covered with all the equipment. Landslides occurred at the weekend when his career was not working, which made it possible to avoid tragedies. The consequences of the disaster were so significant that the conduct of mining activities on the same technological scheme was impossible. In this regard, since 1958, began to translate stripping works on the principle of jetting. With the help of powerful water jet, the top layer of waste rock (he reached the old quarry 38 meters) destroyed and turned into pulp, which dredgers perekachivalasv sea. A relatively thin layer of waste rock and a half - two meters, covering the blue earth & quot ;, filmed many excavator bucket, then yantaronosnaya land or electric trains was delivered by pipeline to the processing plant.

In 1960, the Government made a decision to build a new career with capacity of 1000 tons of amber in the year on the basis of the Primorsky field, located in two or three kilometers east of the village of Amber, which was put into operation only in 1976. But the new quarry did not justify the associated MRC hopes. When designing mistakes have been made, not all of the geological conditions were taken into consideration. Due to the high content of stones razrabaty Vai rocks provided dredgers for the project proved to be unsuitable. After entering the new karerav operation on it producing about 100 tonnes of amber per year. It was necessary to continue work on an old quarry, despite its official closure in 1972. The shortage of raw materials for all major manufacturing plant has been associated with deterioration yantaronosnoy breed. Continue to reduce the proportion of the most valuable large amber. In these difficult conditions, plant management decided to begin work on the seafront in the beach area, located along the coast between the towns Sinyavino and Amber, and are an integral part Palmnikenskogo birthplace. Hydromonitors eroded rocks and through slurry pipeline, it is thrown away by the sea. Thus, it was reclaimed more than 500 meters. Here I was laid another bat. Already in 1972 it produced 450 tons of amber. The advantage of the Beach ESTATE TKA was that the cost of mined amber is 3 times lower than in a new career because of the small depth - only 10-12 meters from the surface (in a new career formation "blue earth" is located at a depth of 50 -60 meters).

The one new bat put into operation in 1976.

...

Quarry was once excavated to a depth of 50-60 meters and then made work amber alluvium already at the bottom of the quarry. Operating controls jetting (water cannon, in a simple way), which provides a stream of water at a pressure of 6 atmospheres and washes away the top layer of waste material, which is then pumped into the sea dredger.

Then, walking draglines removed a thin layer of waste rock covering the blue earth.

And yantaronosnaya land by pipeline is delivered to the processing plant for further processing.

And this old German quarry. Now flooded. It is crystal clear water, and on the far bank of the Moscow oligarchs are building cottages.

Anna Mine. It was opened by the Germans in 1871. She worked until 1924. Here in 1945 was the mass murder of Jews

7000

Let's move on to the production company. There is very strict control of the working collective. After just a few years ago to combine steal tons. And the workers of the plant in the least interested in the wages. Now this is an active struggle. In the mining operator jetting protect a few people at the checkpoint also combine dual control. Number steal amber at the plant is such that in Gdansk (Poland), which is considered the world capital of amber it is enough for a dozen years ahead without any additional purchases from the plant.

There proihodit repeated washing stones coming from the factory.

The raw stones are then sorted

The size fractions.

The larger the stone, the more expensive it is.

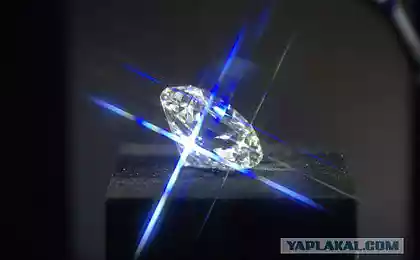

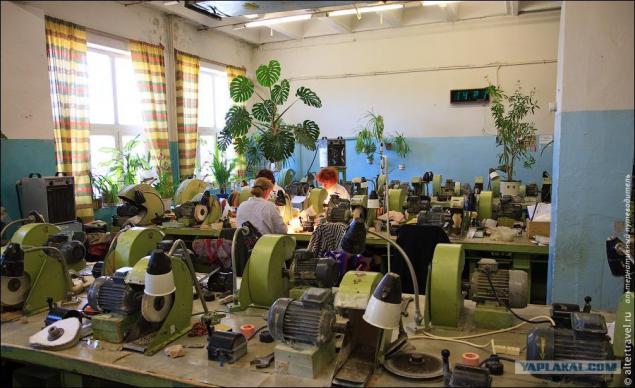

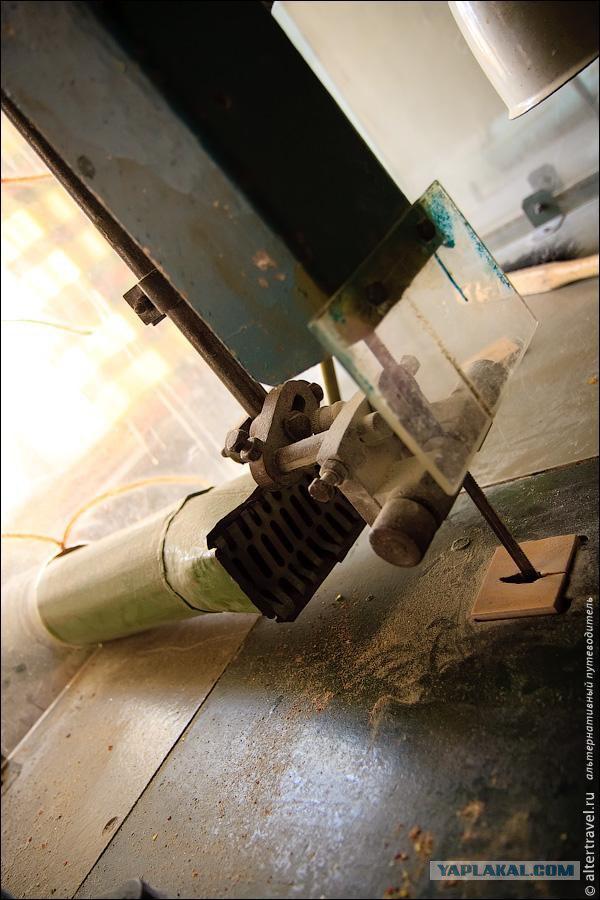

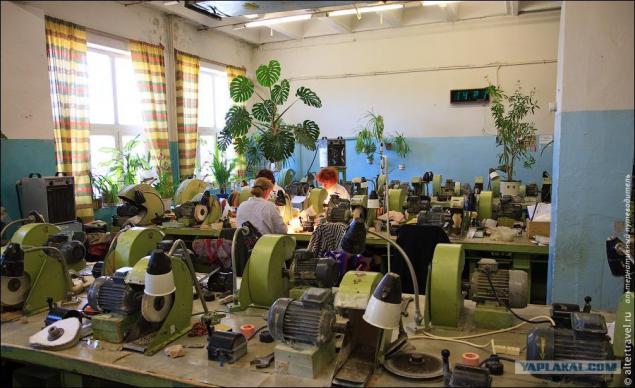

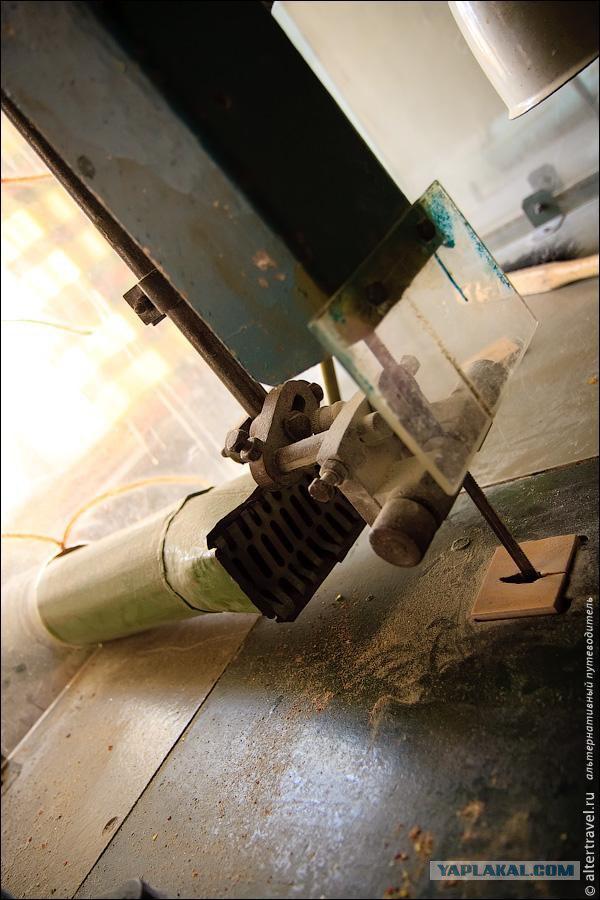

Stone-cutting department.

It produces sharp ...

... And grinding stones.

The entire process is done manually.

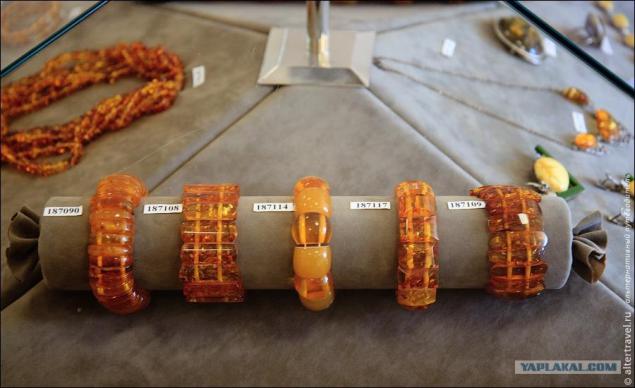

Then polished stones are sorted again.

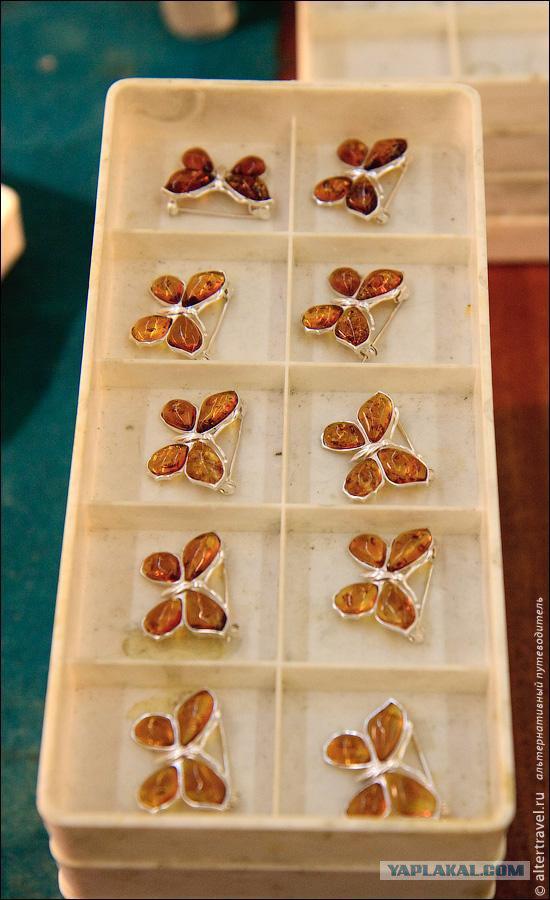

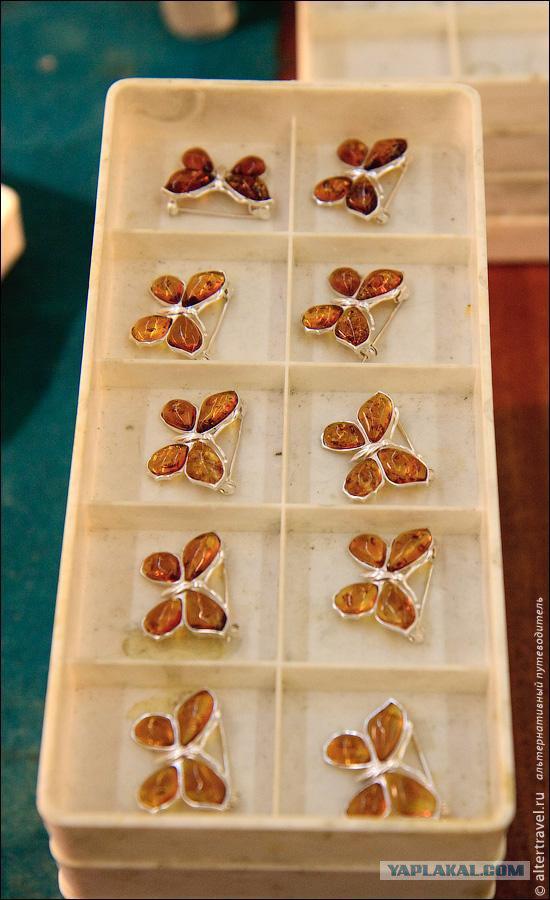

And sent to the assembly.

Where to collect beads and other jewelry.

20

21

And there's workshop where artists and sit with dental boron-cars of the largest amber stone figurines do.

Painstaking manual work.

And you can look at the museum. By the way, in August last year at the plant began to develop a tourist destination. It was open to the public observation deck on the career of the plant, preparing the room for the museum, shop and exhibition history of the plant. While the museum is located on the territory of the plant, but it has a very extensive collection of exhibits.

25

Types of amber.

27

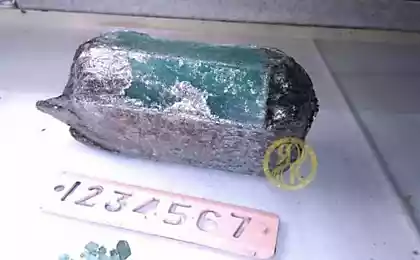

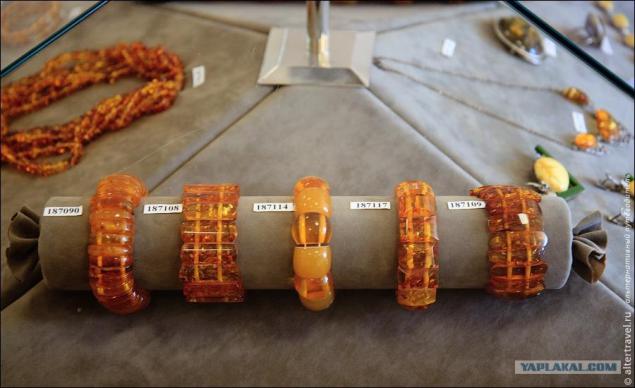

Specially large stones.

The biggest items are stored separately, have their own room and installed cost. Here is the stone weighing 2 to 4 kg costs only $ 3,600.

Various statues.

And found in the past year clamshell, as scientists say that 300 million years.

Generally, in the Amber seychs is actively developing tourist destination, the entire tourism infrastructure is ready, scheduled for the summer many cultural and sporting events. And due to the fact that Amber has a full sandy beach, spend the summer perhaps even better than in Svetlogorsk

Source:

Since ancient times, the Baltic amber collected on the beaches and shallows, where he threw out the sea and used for medicinal, religious, artistic and applied purposes. Over the last three thousand years the Baltic Sea has been collected about 60 thousand tons of the mineral. Since the XVI century on the beaches became popular new method of extraction of amber - fishing. Hunters armed with large nets, 6-8-meter poles went into the water and out to sea in a boat and caught with seaweed tangled in them amber.

31 phot via victorprofessor

For the first time to produce amber land way began in the middle of the XVI century. On the shore of digging holes and, if the ground turned out to be a grain of amber, on the bottom hoed until groundwater. On the surface surfaced pieces of amber. In the middle of the XVII century, attempts were made to dig amber from coastal cliffs. And already in 1871 it was laid the first pit depth of about 30 meters with a view to commercial production of amber near today's village of Sinyavino.

It turned out to be more productive extraction via open-pit mines in the first half of the XIX century. In the richer parts of the coast were laid amber small pits (30 x 30 meters). Layers gangue frustrated and autopsied layer "blue earth", which was developed. But by the beginning of the XX century, underground mining became unprofitable. And in 1912, at a distance from the sea, for the open development of the field, it was laid a large mine, operated for about 60 years, will run out in the early 70s.

Before World War II Palmnikenskom deposit was mined for about 400 tons of raw amber a year: about half of them processed at Koenigsberg Amber Manufactory, which included several factories and workshops in various locations in Eastern Prussia. At the end of 1930 on the amber enterprises Palmniken and Koenigsberg was occupied by more than 2, 5 thousand employees. The same number of workers, mostly women, were hired to support the work in the winter.

When in 1945 the Russian army liberator came to the land of East Prussia, it was quite obvious that the Germans have ceased production of amber before their arrival. Amber quarry was flooded and more like a dead lake yellow.

Mining company functioned under the Germans, it was decided to revive. In warehouses Palmniken after the retreat of German forces left several dozen tons of first-class amber. Thanks to these reserves were organizovanynebolshie workshops, which employ demobilized Soviet soldiers and the rest in the village of German residents. Later workshops were transformed into amber factory in the Voentorg, which were made necklaces, bangles, mouthpieces and souvenirs made of amber, insulators for geological exploration equipment ores of uranium and radium. So there was the first post-war amber products plant.

In 1947, Amber Plant visited a government commission headed by AN Kosygin, who had come to the conclusion about the necessity of its transfer to the Ministry of the Interior, has qualified personnel and experience in the organization of work in the extractive industries. 21 July 1947 the Council of Ministers adopted a decree number 2599 on the transfer of production of amber along with career in the Ministry of Interior of the USSR. The new company was given the name "The plant number 9". Education kombinatane entailed the elimination Yantarnogozavoda trust "Russian gems". The factory was moved to the village of Primorye near Svetlogorsk and tourist center located in the building of "Anchor". In fact, it was one shop, where in the early 50th hgodov labor is not more than 120 people. Raw plant received from the plant number 9, the range of products remained not too rich.

In the fall of 1947 began pumping water from the pit into the sea, from the bottom of the rock was removed, restored the site. At the same time carried out the reconstruction of access roads and repair of the equipment survived. In June 1948, the quarry was put into commercial operation until the end of the year it was produced 115,897 kg of amber raw.

In 1953, the Amber plant was transferred from the Ministry of Internal Affairs of trust "Russian gems" at the same time there was a unification of the plant and the plant. The new management of the plant was formed from the experts sent from Leningrad headed by the first civilian director of the KP Polyakov, who was soon replaced as KN Rizaev. For the efficient operation of the company it was necessary, first of all, to resume commercial production of amber. Steady work career hampered by a lack of equipment and spare parts, lack of qualified specialists. The situation was corrected after in October 1955, this critical section headed VN Rozhkov, an experienced engineer miner. But the possibilities pledged at the beginning of the century career largely been exhausted. Areas with the highest content of Ba amber were successively developed, and the southern part of the most promising deposits remained virtually inaccessible to production due to frequent landslides of soil.

The process of extraction and purification of amber while very different from how it is today. During the first decade after the launch of the plant was designed only quarry excavation method. Overburden of railroad went to the dump, and containing amber "blue earth" on trains delivered for initial processing. The results of a career in the 50s were not high enough. In the year extracted, on average, 240 tons of amber, dominated by his fines, while demand continued to grow Baltic gem.

It was necessary to make a radical renewal of the entire production technology. The push to the top of the reconstruction gave the element. 7 November 1957 and 10 February 1958, one after another, there were two disaster - large landslides of soil, resulting in the bottom of the quarry has fallen more than half a million tons of earth. Failure were excluded almost all of the transport system, covered with all the equipment. Landslides occurred at the weekend when his career was not working, which made it possible to avoid tragedies. The consequences of the disaster were so significant that the conduct of mining activities on the same technological scheme was impossible. In this regard, since 1958, began to translate stripping works on the principle of jetting. With the help of powerful water jet, the top layer of waste rock (he reached the old quarry 38 meters) destroyed and turned into pulp, which dredgers perekachivalasv sea. A relatively thin layer of waste rock and a half - two meters, covering the blue earth & quot ;, filmed many excavator bucket, then yantaronosnaya land or electric trains was delivered by pipeline to the processing plant.

In 1960, the Government made a decision to build a new career with capacity of 1000 tons of amber in the year on the basis of the Primorsky field, located in two or three kilometers east of the village of Amber, which was put into operation only in 1976. But the new quarry did not justify the associated MRC hopes. When designing mistakes have been made, not all of the geological conditions were taken into consideration. Due to the high content of stones razrabaty Vai rocks provided dredgers for the project proved to be unsuitable. After entering the new karerav operation on it producing about 100 tonnes of amber per year. It was necessary to continue work on an old quarry, despite its official closure in 1972. The shortage of raw materials for all major manufacturing plant has been associated with deterioration yantaronosnoy breed. Continue to reduce the proportion of the most valuable large amber. In these difficult conditions, plant management decided to begin work on the seafront in the beach area, located along the coast between the towns Sinyavino and Amber, and are an integral part Palmnikenskogo birthplace. Hydromonitors eroded rocks and through slurry pipeline, it is thrown away by the sea. Thus, it was reclaimed more than 500 meters. Here I was laid another bat. Already in 1972 it produced 450 tons of amber. The advantage of the Beach ESTATE TKA was that the cost of mined amber is 3 times lower than in a new career because of the small depth - only 10-12 meters from the surface (in a new career formation "blue earth" is located at a depth of 50 -60 meters).

The one new bat put into operation in 1976.

...

Quarry was once excavated to a depth of 50-60 meters and then made work amber alluvium already at the bottom of the quarry. Operating controls jetting (water cannon, in a simple way), which provides a stream of water at a pressure of 6 atmospheres and washes away the top layer of waste material, which is then pumped into the sea dredger.

Then, walking draglines removed a thin layer of waste rock covering the blue earth.

And yantaronosnaya land by pipeline is delivered to the processing plant for further processing.

And this old German quarry. Now flooded. It is crystal clear water, and on the far bank of the Moscow oligarchs are building cottages.

Anna Mine. It was opened by the Germans in 1871. She worked until 1924. Here in 1945 was the mass murder of Jews

7000

Let's move on to the production company. There is very strict control of the working collective. After just a few years ago to combine steal tons. And the workers of the plant in the least interested in the wages. Now this is an active struggle. In the mining operator jetting protect a few people at the checkpoint also combine dual control. Number steal amber at the plant is such that in Gdansk (Poland), which is considered the world capital of amber it is enough for a dozen years ahead without any additional purchases from the plant.

There proihodit repeated washing stones coming from the factory.

The raw stones are then sorted

The size fractions.

The larger the stone, the more expensive it is.

Stone-cutting department.

It produces sharp ...

... And grinding stones.

The entire process is done manually.

Then polished stones are sorted again.

And sent to the assembly.

Where to collect beads and other jewelry.

20

21

And there's workshop where artists and sit with dental boron-cars of the largest amber stone figurines do.

Painstaking manual work.

And you can look at the museum. By the way, in August last year at the plant began to develop a tourist destination. It was open to the public observation deck on the career of the plant, preparing the room for the museum, shop and exhibition history of the plant. While the museum is located on the territory of the plant, but it has a very extensive collection of exhibits.

25

Types of amber.

27

Specially large stones.

The biggest items are stored separately, have their own room and installed cost. Here is the stone weighing 2 to 4 kg costs only $ 3,600.

Various statues.

And found in the past year clamshell, as scientists say that 300 million years.

Generally, in the Amber seychs is actively developing tourist destination, the entire tourism infrastructure is ready, scheduled for the summer many cultural and sporting events. And due to the fact that Amber has a full sandy beach, spend the summer perhaps even better than in Svetlogorsk

Source: