886

Electric pipe-welding shop Welding Shop-3 or "Height 239"

Already a lot to learn about what a beautiful plant built in Chelyabinsk in the CTRP. For example the blog Chelyabinsk photographer, or here Kommersant. Here are photos of the finished plant. And how did it all start and build? Now you learn. Pictures very much, will likely have to break apart and do different threads industrial construction is still a long process, in some places is still not finished. A selection please do not break. Whenever possible, letters will give explanations, so a selection will be filled slowly.

To begin with - the complete building, the main façade and a piece of the gallery of energy (here: Blog Photos).

PS

In the blog Chelyabinsk photographer as technical errors, which immediately warn you that if there will be anything to quote sagely, then you know people laugh at, including myself

. Then it can devote the time to describe the technology of pipes separate topic.

This is how the area looked like before the start of construction.

Removing unwanted gantry crane.

All sdemontirovano and started excavation work.

After digging the pit started piling.

Erection of the first column.

View through a series of columns.

That has already begun installation of farms. View from afar.

The height of the mounting frame, just before the 2008 crisis.

In the middle of the third row of shops it was decided to make the cable tunnel for power supply of package transformer substations and switchgear 6 kV. This photograph is filled floor of the tunnel.

That view is almost on top of the plant. Dimensions of the main shop is 720 meters by 150 meters. It is not to attach. Therefore, to understand the magnitude of the pictures is very difficult.

The assembly of the roof inside view.

Mounting internal fire wall.

For wired northern facade of the building.

And now cable tunnel is ready and covered with waterproofing. View of the roof of the tunnel.

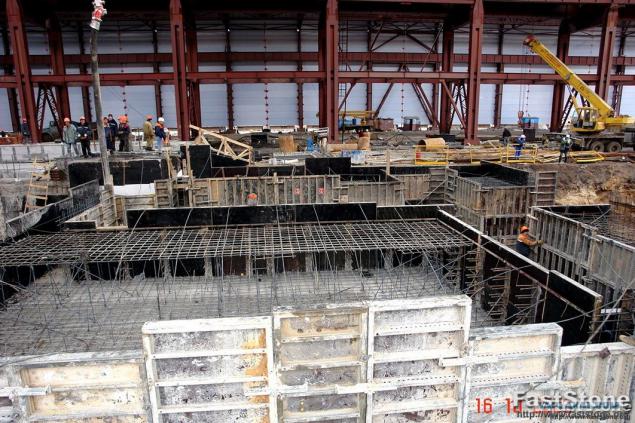

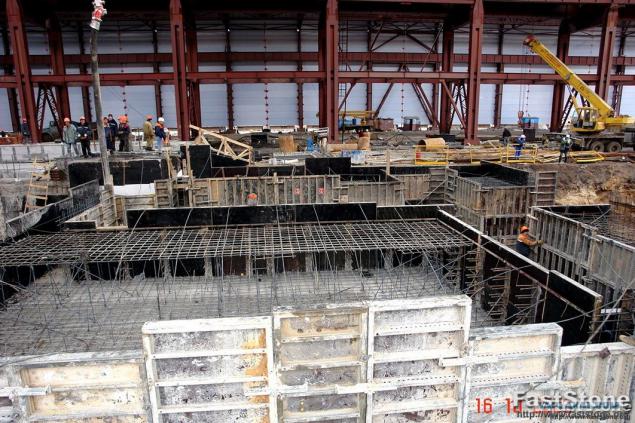

Work has begun on digging pits under the foundations of the process equipment.

White paint is fire protection of bearing metal.

And here, by the way, I missed one photo. Installing formwork for raft foundations.

In the third row of columns passes an observation gallery, which initially was supposed to arrange the room for the staff, and then left alone control room. In this gallery, you can quickly pass along the shop not bypassing all the equipment. Under this gallery space located personnel, KTP, RP 6 kV, with room control equipment manufacturing equipment, communications hung, hang ballasts, etc. etc. Beneath it is just located the cable tunnel. In this photo just seen the rise. Outside the elevator to the main facade can be reached directly at this gallery. This rise on the other side of the building.

With frame and trim shop I finish. Now we show how to establish the foundations for technological equipment. The main shop is in the stepping of the press under 12 (for onshore pipelines) and 18 (for offshore pipelines) meter pipe. In this picture, one foundation is ready and maintained the construction of the second.

Here are both the foundations are ready. View from the gallery.

Here's another view of the foundations of presses. Black - waterproofing concrete to save. From the bottom of pits constantly pumped groundwater. Please pay attention to the human figures in technological recesses.

And at this time I brought up the heavy part of the press. Weight parts power of the press is about 170 to 240 tons. Here are a couple lying in the port of Perm region, where they will carry in Chelyabinsk on special trawls.

And here is the pit, which was dug under the foundation of the press.

So heavy items are loaded onto barges. That crap, which carries parts from the shore to the barge called megalift. To it we shall return.

But the details were being taken to the trawl. Special multi-axial (at each wheel axle 8) are interconnected to share the load and the coupler interconnected to the road surface. They are able to rise and fall, what to see next.

That can be seen in this photograph stands for heavyweights. This platform pulls up, rises, stands inserted under the load platform is lowered and leaves. Ie unloading takes place without the use of a crane. The concept is simple.

But with the help of the press frame of the tractor brought to the shop.

But already mounted in the workshop megalift.

But megalift took the base frame, and start editing. Size tolerances of such parts is very small. Joints may be at a temperature close to 20 degrees Celsius. In the event of a temperature a few degrees to insert bolts into the holes will not be possible. And it does it all on the weight.

But this pin screed. I do not remember now how many meters, but much more than 10.

That view of the megalift side when unloading platform.

But in the end what happened. Like this 12 meter step press.

Here's Circuits at the bottom of the basement.

But the view of the media near the cylinders. Impressive?

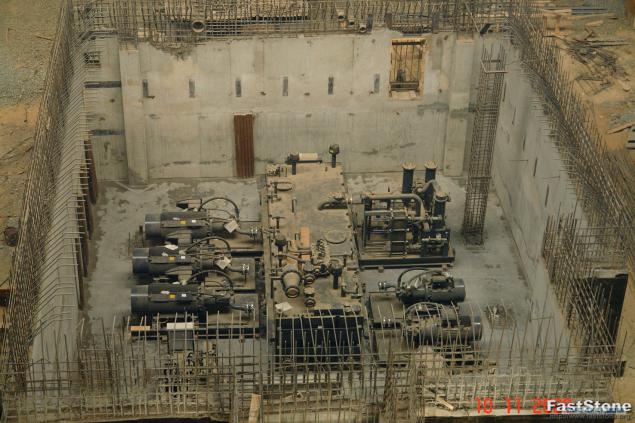

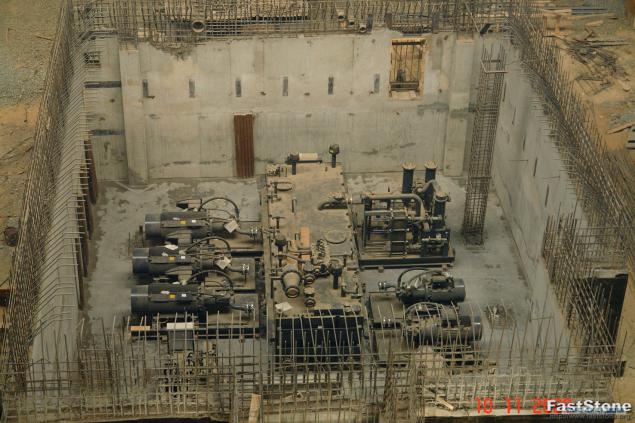

Next to the press, the gidropodvaly with oil pumps.

Here is another view closer.

But did the roof over gidropodvalom. Window left to allow the dismantling of the pump in case of breakage.

Gidropodval view from the other side.

Here's another Circuits with a man in the background. To understand the size of the structures were.

It will be a series of pictures without comment. Equipment with great detail in the shop about twenty units. Just estimate the size of the foundations and details.

As the plant was running safety engineer and took pictures of the characters, then the company where they worked heroes fined.

Installation ponderous detail.

Installers, they are, yes ...

Recreation.

For bases used removable modular formwork. Funny thing.

Another foundation.

View from the gallery shop.

Here's another interesting foundation.

Source:

To begin with - the complete building, the main façade and a piece of the gallery of energy (here: Blog Photos).

PS

In the blog Chelyabinsk photographer as technical errors, which immediately warn you that if there will be anything to quote sagely, then you know people laugh at, including myself

. Then it can devote the time to describe the technology of pipes separate topic.

This is how the area looked like before the start of construction.

Removing unwanted gantry crane.

All sdemontirovano and started excavation work.

After digging the pit started piling.

Erection of the first column.

View through a series of columns.

That has already begun installation of farms. View from afar.

The height of the mounting frame, just before the 2008 crisis.

In the middle of the third row of shops it was decided to make the cable tunnel for power supply of package transformer substations and switchgear 6 kV. This photograph is filled floor of the tunnel.

That view is almost on top of the plant. Dimensions of the main shop is 720 meters by 150 meters. It is not to attach. Therefore, to understand the magnitude of the pictures is very difficult.

The assembly of the roof inside view.

Mounting internal fire wall.

For wired northern facade of the building.

And now cable tunnel is ready and covered with waterproofing. View of the roof of the tunnel.

Work has begun on digging pits under the foundations of the process equipment.

White paint is fire protection of bearing metal.

And here, by the way, I missed one photo. Installing formwork for raft foundations.

In the third row of columns passes an observation gallery, which initially was supposed to arrange the room for the staff, and then left alone control room. In this gallery, you can quickly pass along the shop not bypassing all the equipment. Under this gallery space located personnel, KTP, RP 6 kV, with room control equipment manufacturing equipment, communications hung, hang ballasts, etc. etc. Beneath it is just located the cable tunnel. In this photo just seen the rise. Outside the elevator to the main facade can be reached directly at this gallery. This rise on the other side of the building.

With frame and trim shop I finish. Now we show how to establish the foundations for technological equipment. The main shop is in the stepping of the press under 12 (for onshore pipelines) and 18 (for offshore pipelines) meter pipe. In this picture, one foundation is ready and maintained the construction of the second.

Here are both the foundations are ready. View from the gallery.

Here's another view of the foundations of presses. Black - waterproofing concrete to save. From the bottom of pits constantly pumped groundwater. Please pay attention to the human figures in technological recesses.

And at this time I brought up the heavy part of the press. Weight parts power of the press is about 170 to 240 tons. Here are a couple lying in the port of Perm region, where they will carry in Chelyabinsk on special trawls.

And here is the pit, which was dug under the foundation of the press.

So heavy items are loaded onto barges. That crap, which carries parts from the shore to the barge called megalift. To it we shall return.

But the details were being taken to the trawl. Special multi-axial (at each wheel axle 8) are interconnected to share the load and the coupler interconnected to the road surface. They are able to rise and fall, what to see next.

That can be seen in this photograph stands for heavyweights. This platform pulls up, rises, stands inserted under the load platform is lowered and leaves. Ie unloading takes place without the use of a crane. The concept is simple.

But with the help of the press frame of the tractor brought to the shop.

But already mounted in the workshop megalift.

But megalift took the base frame, and start editing. Size tolerances of such parts is very small. Joints may be at a temperature close to 20 degrees Celsius. In the event of a temperature a few degrees to insert bolts into the holes will not be possible. And it does it all on the weight.

But this pin screed. I do not remember now how many meters, but much more than 10.

That view of the megalift side when unloading platform.

But in the end what happened. Like this 12 meter step press.

Here's Circuits at the bottom of the basement.

But the view of the media near the cylinders. Impressive?

Next to the press, the gidropodvaly with oil pumps.

Here is another view closer.

But did the roof over gidropodvalom. Window left to allow the dismantling of the pump in case of breakage.

Gidropodval view from the other side.

Here's another Circuits with a man in the background. To understand the size of the structures were.

It will be a series of pictures without comment. Equipment with great detail in the shop about twenty units. Just estimate the size of the foundations and details.

As the plant was running safety engineer and took pictures of the characters, then the company where they worked heroes fined.

Installation ponderous detail.

Installers, they are, yes ...

Recreation.

For bases used removable modular formwork. Funny thing.

Another foundation.

View from the gallery shop.

Here's another interesting foundation.

Source: