886

How to make puff

Christina writes Patupchyk:

It is this: "puff" rather than "jackets", calls his domestic producers of tourist equipment «Bask», sponsored, by the way, the expedition of Fedor Konyukhov.

Their clothing was seen Medvedev during a visit to Kamchatka in 2008, it was the same environment Putin when he put the transmitter on the polar bear.

The most famous model of their jackets to visit all the vertices and eight thousand meter-deserved reputation among professionals not only in our country but also abroad: in the United States and Kanade, Skandinavii (Shvetsii, Finland and Nopvegii) Yuzhnoy Kopee and India Slovenii and Chile, Latvii and even in Israel. We have a unique opportunity to see how it is made.

- What ... - call hyped on TV well-known manufacturer technical outdoor clothing.

- What do you! Neither climber not wear their clothes. You do not confuse hyped advertising brand and a serious professional equipment. With nothing beats down any weight or by volume transport.

- Here we have a pilot plant, then practiced the new models.

...

...

...

...

...

...

...

In the manufacture of jackets, a special membrane fabric, they can not be dry cleaned only wash. But you can pay the manufacturer for "maintenance" and repair all the rules.

...

Here is the goose down. He's going in vivo, but not with the dead bird.

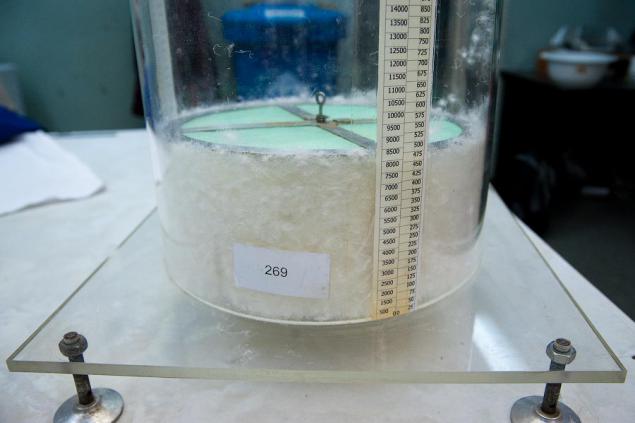

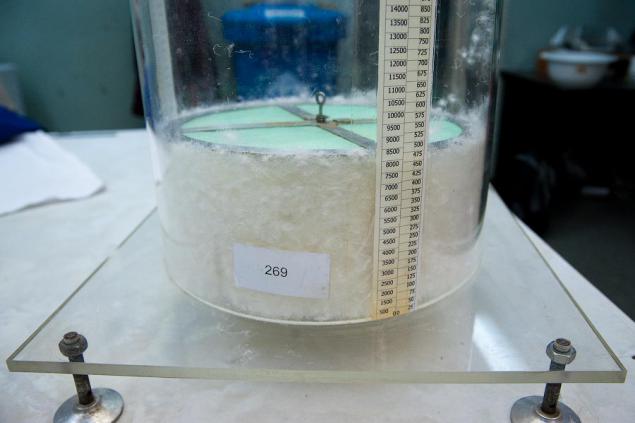

Test Lab.

Each lot of fluff, despite all the certificates held here verification. Take one ounce and is put under the yoke of a certain time. After that fluff must deal to the desired value.

This indicator «Fill Power» is fundamental in determining quality.

One hundred percent down is not the case, 93% - the maximum, the size of feathers from three to five millimeters, not more. In their feathers can not be detected even in this percentage.

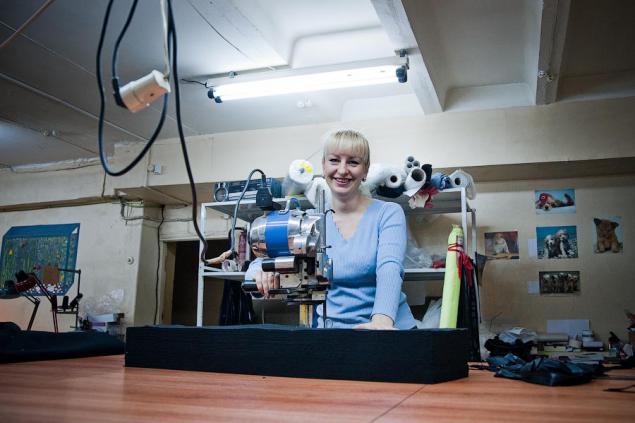

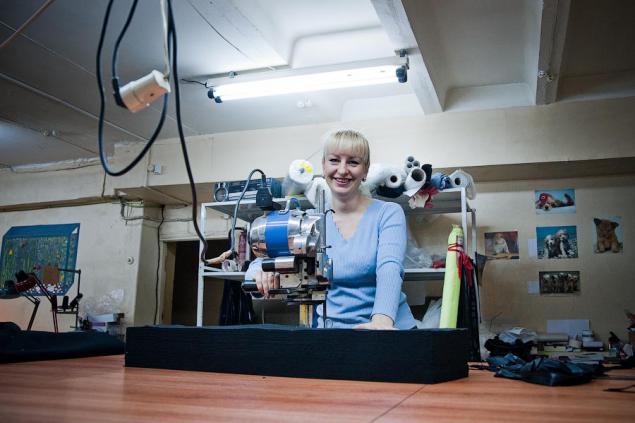

The main production. It is worth noting that all enterprises of the Russian light industry look the same. The main thing - the equipment, experience and hands.

...

...

...

...

...

...

...

...

Case jacket consists of three hundred to eight parts. This product retained technological openings through which it then filled with down. Tape technology - know-how. Thanks to the jackets are no pass-through suture needle that is never breaks through the entire fabric.

And now the most interesting - a feather shop.

First, the collar was taped as it is the Sticky fluff Jacket.

And then he stuffed special bags, which are inserted into the product. Thanks to them, is not allowed vylezanija down outside. The company ensures that even wearing a jacket over the suit, and such sluchetsya often enough in modern business, excluded the possibility of "feather" on the jacket.

This product uses a goose down Russian producers included in the "European Association of down and feathers." Despite its funny name, such fluff after collecting a duck takes 18 stages of processing.

Clothing and eider feathers sewn customized after removal of the test measurements and manufacturing products on the usual fluff. There is such a jacket over a hundred and fifty thousand rubles.

Ezhegodno vo vsem mipe going in only 4 tons gagachego puha. The cost of a kilogram - 2,000 euros when purchased in bulk. In the jacket is about 450 grams. Thus year thereof can be crosslinked around 9000 products. Such fluff going from nests during the nesting eiders. From one nest only 16 grams, and, naturally, they are not the most easily accessible places.

In contrast to the goose, down eider does not scatter. This is particularly important in extreme conditions, for example, if the jacket cut.

Despite the fact that the warmer and lighter down all other fillers, it is not ideal. Such clothing should not be worn where high humidity, such as in Antarctica.

...

...

...

Air under pressure - the best way to get rid of the fluff.

...

...

...

...

...

Final cleaning products. Air, sponge and scissors.

...

...

Division of Technology. Here are born new models.

...

...

And finally - the finished products. So we see them in the store.

via krispotupchik

Source:

It is this: "puff" rather than "jackets", calls his domestic producers of tourist equipment «Bask», sponsored, by the way, the expedition of Fedor Konyukhov.

Their clothing was seen Medvedev during a visit to Kamchatka in 2008, it was the same environment Putin when he put the transmitter on the polar bear.

The most famous model of their jackets to visit all the vertices and eight thousand meter-deserved reputation among professionals not only in our country but also abroad: in the United States and Kanade, Skandinavii (Shvetsii, Finland and Nopvegii) Yuzhnoy Kopee and India Slovenii and Chile, Latvii and even in Israel. We have a unique opportunity to see how it is made.

- What ... - call hyped on TV well-known manufacturer technical outdoor clothing.

- What do you! Neither climber not wear their clothes. You do not confuse hyped advertising brand and a serious professional equipment. With nothing beats down any weight or by volume transport.

- Here we have a pilot plant, then practiced the new models.

...

...

...

...

...

...

...

In the manufacture of jackets, a special membrane fabric, they can not be dry cleaned only wash. But you can pay the manufacturer for "maintenance" and repair all the rules.

...

Here is the goose down. He's going in vivo, but not with the dead bird.

Test Lab.

Each lot of fluff, despite all the certificates held here verification. Take one ounce and is put under the yoke of a certain time. After that fluff must deal to the desired value.

This indicator «Fill Power» is fundamental in determining quality.

One hundred percent down is not the case, 93% - the maximum, the size of feathers from three to five millimeters, not more. In their feathers can not be detected even in this percentage.

The main production. It is worth noting that all enterprises of the Russian light industry look the same. The main thing - the equipment, experience and hands.

...

...

...

...

...

...

...

...

Case jacket consists of three hundred to eight parts. This product retained technological openings through which it then filled with down. Tape technology - know-how. Thanks to the jackets are no pass-through suture needle that is never breaks through the entire fabric.

And now the most interesting - a feather shop.

First, the collar was taped as it is the Sticky fluff Jacket.

And then he stuffed special bags, which are inserted into the product. Thanks to them, is not allowed vylezanija down outside. The company ensures that even wearing a jacket over the suit, and such sluchetsya often enough in modern business, excluded the possibility of "feather" on the jacket.

This product uses a goose down Russian producers included in the "European Association of down and feathers." Despite its funny name, such fluff after collecting a duck takes 18 stages of processing.

Clothing and eider feathers sewn customized after removal of the test measurements and manufacturing products on the usual fluff. There is such a jacket over a hundred and fifty thousand rubles.

Ezhegodno vo vsem mipe going in only 4 tons gagachego puha. The cost of a kilogram - 2,000 euros when purchased in bulk. In the jacket is about 450 grams. Thus year thereof can be crosslinked around 9000 products. Such fluff going from nests during the nesting eiders. From one nest only 16 grams, and, naturally, they are not the most easily accessible places.

In contrast to the goose, down eider does not scatter. This is particularly important in extreme conditions, for example, if the jacket cut.

Despite the fact that the warmer and lighter down all other fillers, it is not ideal. Such clothing should not be worn where high humidity, such as in Antarctica.

...

...

...

Air under pressure - the best way to get rid of the fluff.

...

...

...

...

...

Final cleaning products. Air, sponge and scissors.

...

...

Division of Technology. Here are born new models.

...

...

And finally - the finished products. So we see them in the store.

via krispotupchik

Source: