592

Rodina "humpback"

For quality photos much I apologize, but the plant for incineration of photographers did not send.

The other day, the third meeting of Ukrainian Lanos clan in a nice resort city of Zaporozhye. The program was scheduled tour of the city, a grand gathering of 170 participants (not counting their satellites), and an excursion to AvtoZAZ.

About an official and not the official part ShSleta as it was christened the club members, I will not tell. This was, perhaps, in another topic, but photos from the factory to conceal absolutely no power and therefore share

Temko can break.

PS. spizhzheny footage borrowed from the board of the club.

We have gathered a decent number of crews and the people still tightened. Total estimated group of about 90 people ... Generally Lanos in Zaporizhia and Sensei on every corner, but I think in the form of a column Daewoo with symbols and flags from the local club with a bang woke gag reflex patriotism.

On behalf of the plant we were greeted by the press secretary of the AvtoZAZ and spent half a minute briefing on TB which indicated that: poke a finger in a particularly sensitive instruments nizya and overstep the line on the floor, too, is prohibited, as well as that smokers should smoke a reserve.

Our transport. Also brainchild ZAZ

We disembarked at the shop presses. The group was divided into two parts and secured for each engineer. We were given headphones through which led a tour, but they have not got everything (all 48sht) and I could not hear everything the guide said ,

That came in stamping plant, which produces about 400 types of parts. The guide said that for each part can be used sequentially to 4 stamping operations.

The line is almost completely automated. The equipment is programmed and operates without human intervention, although they are always there watching the process. Robot with blank sheet sets suckers should be removed from the finished stamp machine moves to the next and so on. The item is removed from the line, hand formed into containers for transport and travel to the assembly plant.

VIDEO

This shop made all the body parts and plastic parts of the passenger compartment.

Yes! and it works great!

Then we moved to the shop welding and assembly. In general, the scale of production are amazing! Workshops huge, brightly lit and amazingly clean. The floors are washed twice in a shift.

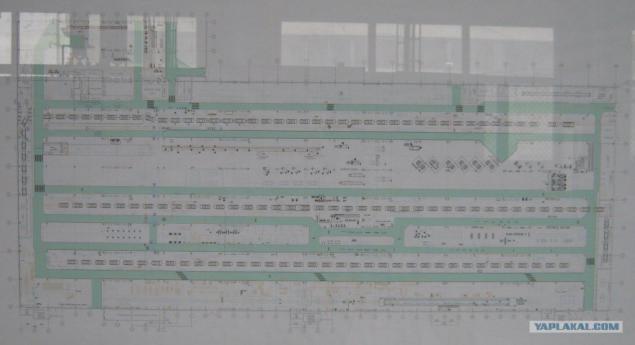

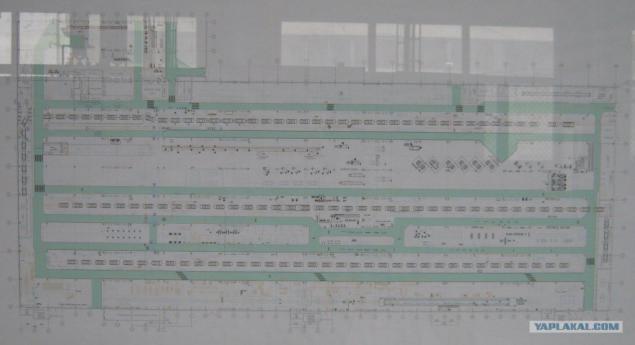

Here for example the first floor of the assembly shop (there are 3, it seems)

It looks like an assembly line welding Lanos and Sensei, but to see how this happens I could not, because the plan for these models has already been completed and the line is idle.

Taki Navara with a margin. Proof

Further seen CKD assembly line of Chevrolet Aveo, Forza and type.

On the line 3 of the robot body in a pile of boiled (all spot welding), at what fit different body, and robots on the control points themselves determine which model they cook

That nice video on the subject.

Something cook a little longer manually

Fasten the doors, hood and trunk.

With that gap is not manually as AvtoVAZ, and once at the assembly and are set automatically by robots. As at each site, at this stage mounted controller (see the woman in the form) that checks the abnormalities in operations and rejects cars.

Ischo control

With the conveyor car takes special crane with the seizure and is on the third floor of the paint shop.

But first, it is prepared by the primer, and then dipped in a bath with the ground. Priming is carried out by electrolysis process is very evenly truly spectacular VIDEO

Then go to the body before the paint-spraying preparation, and in the meantime dried.

Painting is fully automated and is done by airless spray. The robots themselves recognize reference points on the body and in accordance with the program applied to the paint and lacquer under the same angle to the entire surface, and provides an excellent paint. What's interesting - the change of colors in spray guns in less than a minute. When I painted the blue wagon, have lost track blew dispensers and white body ...

Enjoy: VIDEO

Then the body is going to dry and quality control of painting. Waste machine wrapped the film and sent to repainting.

Then we moved into the assembly shop. When assembling the "stuffing" of the wings and bumper protected by special pads and all the doors are removed to avoid damage.

On the assembly line, about 80% of the workforce - women. Just guys do not stand a long repetition of the same operations, and in every part of the change takes place about 350 bodies, and the operator "nabegivaet" up to 17 km per shift.

Plastic parts are assembled on the other side of the conveyor.

Put the engine hodovka, wheels and other miscellaneous, what I do not understand.

The machine is almost ready.

Dviglo

It is necessary to test and configure the main components.

Wheel alignment and bleeding brakes

Check the brake system. At first the front and then the rear ...

Well, that's all. Clippers ready, shipping and export.

Source:

The other day, the third meeting of Ukrainian Lanos clan in a nice resort city of Zaporozhye. The program was scheduled tour of the city, a grand gathering of 170 participants (not counting their satellites), and an excursion to AvtoZAZ.

About an official and not the official part ShSleta as it was christened the club members, I will not tell. This was, perhaps, in another topic, but photos from the factory to conceal absolutely no power and therefore share

Temko can break.

PS. spizhzheny footage borrowed from the board of the club.

We have gathered a decent number of crews and the people still tightened. Total estimated group of about 90 people ... Generally Lanos in Zaporizhia and Sensei on every corner, but I think in the form of a column Daewoo with symbols and flags from the local club with a bang woke gag reflex patriotism.

On behalf of the plant we were greeted by the press secretary of the AvtoZAZ and spent half a minute briefing on TB which indicated that: poke a finger in a particularly sensitive instruments nizya and overstep the line on the floor, too, is prohibited, as well as that smokers should smoke a reserve.

Our transport. Also brainchild ZAZ

We disembarked at the shop presses. The group was divided into two parts and secured for each engineer. We were given headphones through which led a tour, but they have not got everything (all 48sht) and I could not hear everything the guide said ,

That came in stamping plant, which produces about 400 types of parts. The guide said that for each part can be used sequentially to 4 stamping operations.

The line is almost completely automated. The equipment is programmed and operates without human intervention, although they are always there watching the process. Robot with blank sheet sets suckers should be removed from the finished stamp machine moves to the next and so on. The item is removed from the line, hand formed into containers for transport and travel to the assembly plant.

VIDEO

This shop made all the body parts and plastic parts of the passenger compartment.

Yes! and it works great!

Then we moved to the shop welding and assembly. In general, the scale of production are amazing! Workshops huge, brightly lit and amazingly clean. The floors are washed twice in a shift.

Here for example the first floor of the assembly shop (there are 3, it seems)

It looks like an assembly line welding Lanos and Sensei, but to see how this happens I could not, because the plan for these models has already been completed and the line is idle.

Taki Navara with a margin. Proof

Further seen CKD assembly line of Chevrolet Aveo, Forza and type.

On the line 3 of the robot body in a pile of boiled (all spot welding), at what fit different body, and robots on the control points themselves determine which model they cook

That nice video on the subject.

Something cook a little longer manually

Fasten the doors, hood and trunk.

With that gap is not manually as AvtoVAZ, and once at the assembly and are set automatically by robots. As at each site, at this stage mounted controller (see the woman in the form) that checks the abnormalities in operations and rejects cars.

Ischo control

With the conveyor car takes special crane with the seizure and is on the third floor of the paint shop.

But first, it is prepared by the primer, and then dipped in a bath with the ground. Priming is carried out by electrolysis process is very evenly truly spectacular VIDEO

Then go to the body before the paint-spraying preparation, and in the meantime dried.

Painting is fully automated and is done by airless spray. The robots themselves recognize reference points on the body and in accordance with the program applied to the paint and lacquer under the same angle to the entire surface, and provides an excellent paint. What's interesting - the change of colors in spray guns in less than a minute. When I painted the blue wagon, have lost track blew dispensers and white body ...

Enjoy: VIDEO

Then the body is going to dry and quality control of painting. Waste machine wrapped the film and sent to repainting.

Then we moved into the assembly shop. When assembling the "stuffing" of the wings and bumper protected by special pads and all the doors are removed to avoid damage.

On the assembly line, about 80% of the workforce - women. Just guys do not stand a long repetition of the same operations, and in every part of the change takes place about 350 bodies, and the operator "nabegivaet" up to 17 km per shift.

Plastic parts are assembled on the other side of the conveyor.

Put the engine hodovka, wheels and other miscellaneous, what I do not understand.

The machine is almost ready.

Dviglo

It is necessary to test and configure the main components.

Wheel alignment and bleeding brakes

Check the brake system. At first the front and then the rear ...

Well, that's all. Clippers ready, shipping and export.

Source: