986

Make a Li-Po battery for the screwdriver.

Please do not break the will of 10 photos and text.

I've got here is such a screwdriver firm "Makita". He has 6 years probably, if not more. It is not a native cartridge (by the way, better than the original cartridge) and replaced the gearbox. Now came the turn of anything to do with the batteries - they are pretty podrasteryali capacity (more than 2 times), and a full charge may not be enough even for a few long screws.

Solutions to the problem may be several:

1. Buy a new screwdriver. The simplest, but also the most expensive. However, I like my old one, and I do not like to throw out what else can serve more.

2. Buy home batteries. The service they cost about 2000r apiece, "Leroy" I saw them in 1400, I think they just by defective or incomplete sets.

3. Go for something more recent than the Ni-Cd, and, accordingly, replace the batteries.

Was chosen the third option, besides my own charge for a long time it did not work, so the batteries charge for a "smart" universal charging Imax-B6.

One could, of course, just below primotat Li-Po battery of any size - but it's not nice, and not comfortable ... Therefore it was decided to replace the stuffing in the battery - to establish a new Li-Po in the old building.

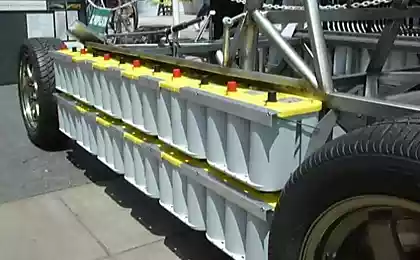

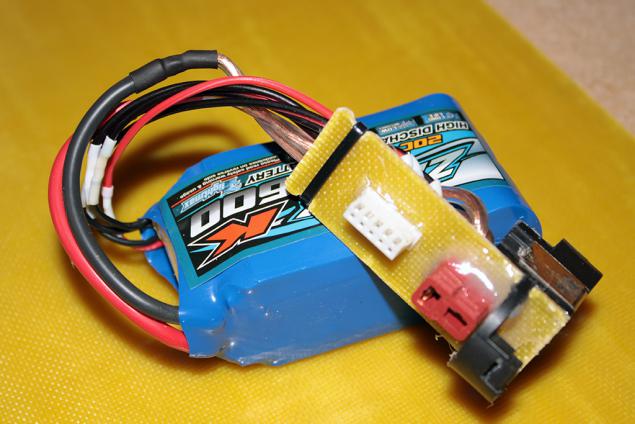

After searching in the Chinese online shops was selected here is such a battery ZIPPY-K 4S, 20C. Rated voltage turns a bit more than the original 14.8V 14.4V against the old, but it's for the best - will be "more powerful." It costs just 300 rubles ($ 9.99 on HobbyKing) + shipping.

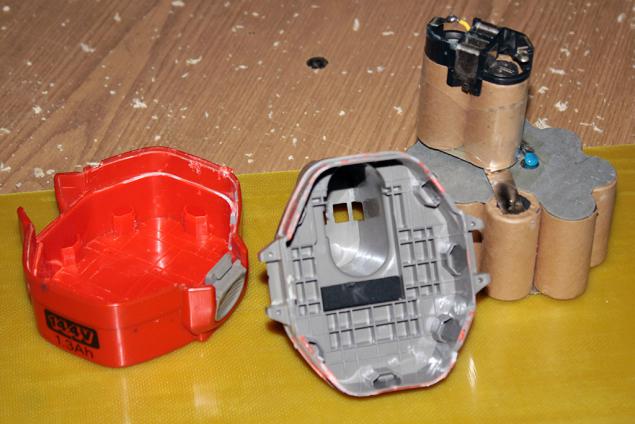

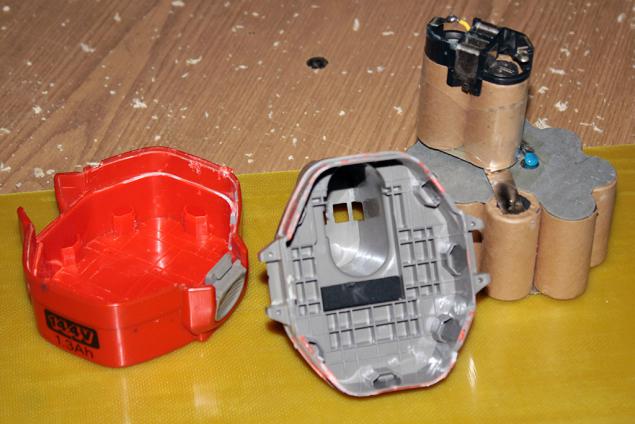

Here it is our old battery. Alas, it is glued, so it just did not make it out. After some bullying, the battery is somewhat messy to understand.

And that's what we have inside. Ni-Cd, banks are no longer needed, they can later be discarded.

In the upper part of the body making holes 2 connectors - balanced and T-shaped. The first is needed to balance the battery during charging. And in the second will be charged. Actually, instead of the T-shaped one can take any other slot, but I have it widely, which is why it was chosen. In principle, you can do without it, and to charge, hold crocodiles main contacts (as I have done before), but it was decided to do a little bit more difficult, but more versatile - if this battery can be connected without any problems anything else.

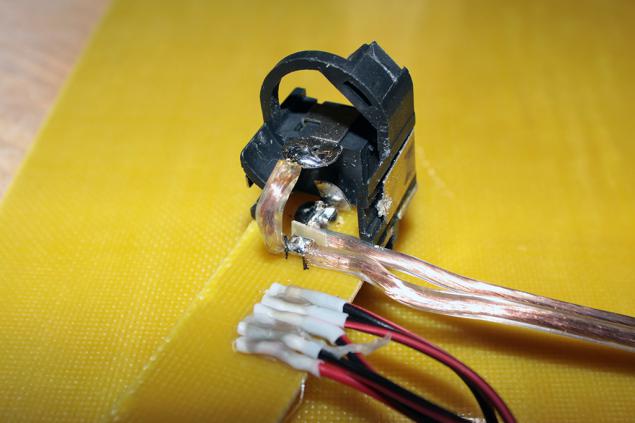

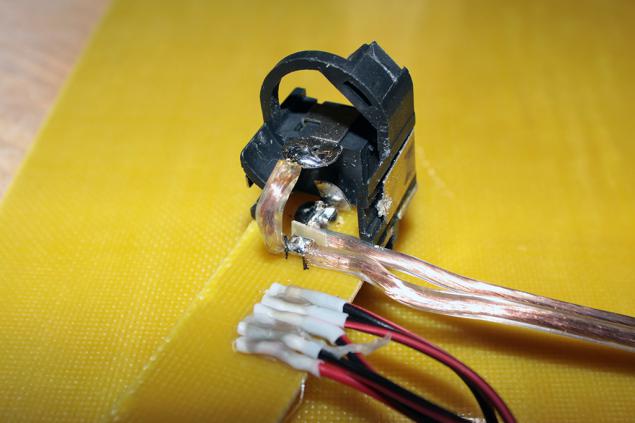

Separated from the old jars contact group. To her soldered 2 "extra" contact and a temperature sensor. Remove all unnecessary, leaving only the working relationship (to find out what work - look at the screwdriver handle)

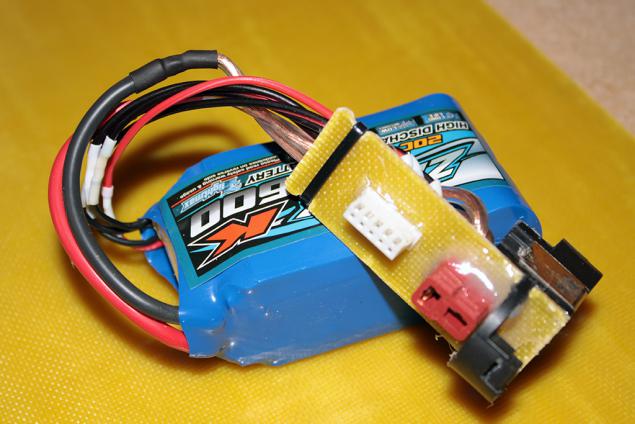

The new connector is glued to the textolite plate, which in turn is glued into the connector. Solder wire extension (native wire battery is not enough). When cutting the balancer connector, it is worth considering that all contacts are energized, so cut the wires one by one and make sure that is not closed. However, you can not cut off the connectors, just solder or buy extension cords.

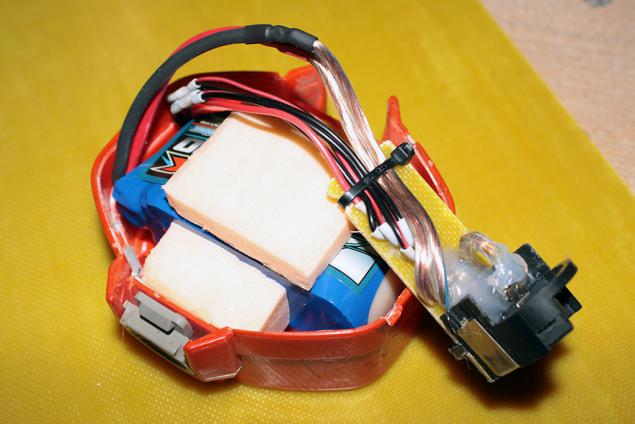

Solder the battery to the wires are not hung - fasten their screed, fill it with hot melt for rigidity.

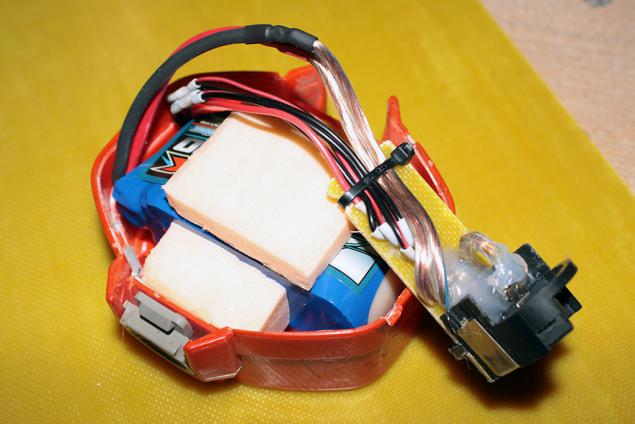

We place all in the old building. The battery is glued with hot melt to the bottom, on the sides of the foam layer inserted - that if anything, he was not talking.

We are putting it all finally glue the halves again with superglue. The new battery also lighter - 260g, 620g and the old.

Rated voltage of the new bit more - 14.8V

The capacity is also greater - 1600mAch against 1300mAch

In the future, it will be necessary to add a screwdriver in squeaker that will beep when a critical low battery (Li-Po do not like much discharge)

Posted in [mergetime] 1357826098 [/ mergetime]

It's all.

Author I'm wondering if - I will answer questions for a while ...

Source:

I've got here is such a screwdriver firm "Makita". He has 6 years probably, if not more. It is not a native cartridge (by the way, better than the original cartridge) and replaced the gearbox. Now came the turn of anything to do with the batteries - they are pretty podrasteryali capacity (more than 2 times), and a full charge may not be enough even for a few long screws.

Solutions to the problem may be several:

1. Buy a new screwdriver. The simplest, but also the most expensive. However, I like my old one, and I do not like to throw out what else can serve more.

2. Buy home batteries. The service they cost about 2000r apiece, "Leroy" I saw them in 1400, I think they just by defective or incomplete sets.

3. Go for something more recent than the Ni-Cd, and, accordingly, replace the batteries.

Was chosen the third option, besides my own charge for a long time it did not work, so the batteries charge for a "smart" universal charging Imax-B6.

One could, of course, just below primotat Li-Po battery of any size - but it's not nice, and not comfortable ... Therefore it was decided to replace the stuffing in the battery - to establish a new Li-Po in the old building.

After searching in the Chinese online shops was selected here is such a battery ZIPPY-K 4S, 20C. Rated voltage turns a bit more than the original 14.8V 14.4V against the old, but it's for the best - will be "more powerful." It costs just 300 rubles ($ 9.99 on HobbyKing) + shipping.

Here it is our old battery. Alas, it is glued, so it just did not make it out. After some bullying, the battery is somewhat messy to understand.

And that's what we have inside. Ni-Cd, banks are no longer needed, they can later be discarded.

In the upper part of the body making holes 2 connectors - balanced and T-shaped. The first is needed to balance the battery during charging. And in the second will be charged. Actually, instead of the T-shaped one can take any other slot, but I have it widely, which is why it was chosen. In principle, you can do without it, and to charge, hold crocodiles main contacts (as I have done before), but it was decided to do a little bit more difficult, but more versatile - if this battery can be connected without any problems anything else.

Separated from the old jars contact group. To her soldered 2 "extra" contact and a temperature sensor. Remove all unnecessary, leaving only the working relationship (to find out what work - look at the screwdriver handle)

The new connector is glued to the textolite plate, which in turn is glued into the connector. Solder wire extension (native wire battery is not enough). When cutting the balancer connector, it is worth considering that all contacts are energized, so cut the wires one by one and make sure that is not closed. However, you can not cut off the connectors, just solder or buy extension cords.

Solder the battery to the wires are not hung - fasten their screed, fill it with hot melt for rigidity.

We place all in the old building. The battery is glued with hot melt to the bottom, on the sides of the foam layer inserted - that if anything, he was not talking.

We are putting it all finally glue the halves again with superglue. The new battery also lighter - 260g, 620g and the old.

Rated voltage of the new bit more - 14.8V

The capacity is also greater - 1600mAch against 1300mAch

In the future, it will be necessary to add a screwdriver in squeaker that will beep when a critical low battery (Li-Po do not like much discharge)

Posted in [mergetime] 1357826098 [/ mergetime]

It's all.

Author I'm wondering if - I will answer questions for a while ...

Source: