852

Body repair. second chance.

Does the right to future life car with such injuries?

My answer is - yes !!!

anticipating the posts of inappropriate repairs and further exploitation bezopastnostnoy cars, along the threads will try to dispel all the myths)

here it is in all its glory.

will be a lot of pictures. Quantity 70

I came to repair the winter

hall at the top of the B-pillar

rear doors barely opened

front had to be removed from the loop, after removing the wing.

without doors it can be seen that the average desk has climbed far into the interior

Machine driven into the stocks.

brought spare

initially wanted to put a full sidewall to the rear quarter, but the owner of Dogo could not find one. across a whole quarter of a sidewall. Well there is something there.

strip all unnecessary

I cut further, but it is then useful

Rear whole leg removed

further otsverlivaetsya inner arch. remnants of parts waiting for better times.

Originally, I was advised that the machine is not for sale, and perhaps for a long period of operation. on this occasion I decided to leave the power elements of the body in the plant form, ie does not cut it and cook and otsverlivat all power components and welded them in the factory outlets. With the whole brought sidewall + quarter would have been much easier, but then had to poizvraschatsya okay tie.

gradually removed from the body of the sick elements. all the internal arch of the back, the arrow shows a joint, because of which it amputated.

Align could certainly, but the rear wing of the new will not be (((so at least on the arch update will cut an old tin.

retired

with pre-welded parts otsverlennuyu

That's the way the general form of a car without all the side racks

I cling to the slipway crane and kept going the whole sidewall

below the junction of the sidewall of the control points (leaf with the dimensions seen in the photo). and an indirect confirmation of the fact that his side stands in place are a convergence of points of contact regime otsverlennyh me welding (marked with red arrows)

any further welded amplifiers. all points on the factory))

I treat the weld anticorrosive primer, as after installation of the wing will make it problematic.

view from cabin after welding

antikorm handled every

Rear arch inner side

front desk after welding

it after upgrading)

could of course be removed from the sidewall peel some amplifiers and put them in exchange damaged. but so much easier. First save the entire lower basket with both racks with amplifiers in the plant as in the second hell then someone dokapalis sidewall that changed and third most important welding pominimumu.

Then you can move on to the top sheet, ie, piece rear wing.

since the new wing is not planned (very long to explain why))), will be one of the two mold. remember what it was.

come to the aid of the instruments of PDR, simply put mushrooms kleeym) rear rack must say I have prepared in advance.

further put the peel, which was previously otsverlena of parts. Many hope to understand why I did otsverlival.

It boils finally, at long intervals, so that the iron from the welding heat is not led.

That's the way a pile of iron left over from repair

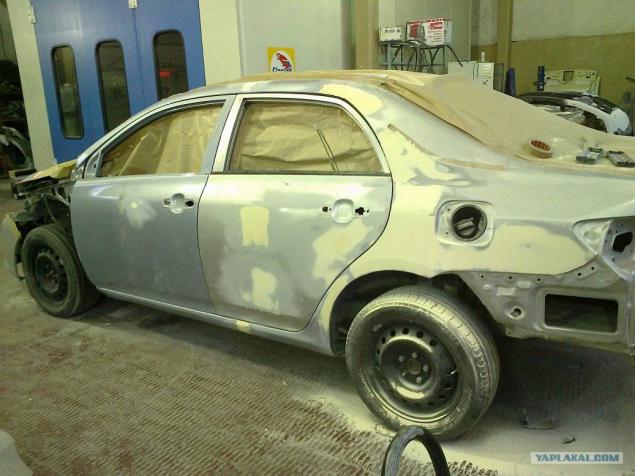

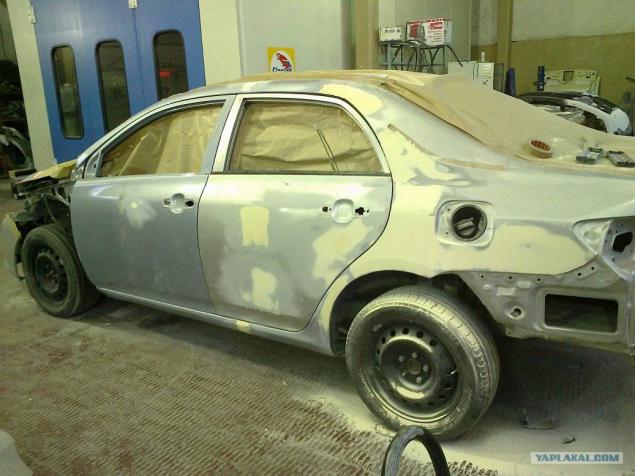

Further machine goes into preparation. Unfortunately I'm not prepared for it, so no pictures. only managed to do))

but the report goes on, since I painted this car)))

after preparation and primer to drive to the car wash, to wash off all the dust

special attention to the painting is not sharpened, longer paid disguise. If that question;)

at the beginning of masking always first place not to be sealed with adhesive tape color, so more precise turns, than later with paper or pieces ukryvki mold. tight bends or narrow areas are sealed nakroynyak contour tape. often come across a car where you have to mask the glass with a rubber molding, with a simple tape can be busy for a long time, comes to the aid is such garbage from 3M

a closer look shows how rising molding. Paint flies under the gum, and then accurately nor any delamination is not molding and not be painted.

Well on tape as the ranshe wrote

and paper

paper the way made it a rule to glue a very long time, since the film is sometimes come off a piece stuck in the base is not the most appropriate time & gt;: D

openings in the paper do not accidentally slammed with cabin secured stretching

the remaining surface, located far from a simple gun hiding ukryvochnoy film.

silver color, very nasty after Pearl, so I paint the same pistol how colorist worked. All clear on the technology first layer of the second 70% 100% 30% third dusted painted must say glazuritovskoy water

After each layer is drying Dry jets

Varnish, the most beautiful and beloved by me)))

More beauty

raspokoval exit

Then came the work of the assembly fitters. in some moments I pouchavstvoval))

fining the scope of the factory doors vinill film type.

glue all around the plant, even with zagibmi.

This kind of the opposite frame factory

far view

any nakleechki

Now in place

Well, the last 4 pictures

time

Two

Three

four. You can zapinyvat)))

Source:

My answer is - yes !!!

anticipating the posts of inappropriate repairs and further exploitation bezopastnostnoy cars, along the threads will try to dispel all the myths)

here it is in all its glory.

will be a lot of pictures. Quantity 70

I came to repair the winter

hall at the top of the B-pillar

rear doors barely opened

front had to be removed from the loop, after removing the wing.

without doors it can be seen that the average desk has climbed far into the interior

Machine driven into the stocks.

brought spare

initially wanted to put a full sidewall to the rear quarter, but the owner of Dogo could not find one. across a whole quarter of a sidewall. Well there is something there.

strip all unnecessary

I cut further, but it is then useful

Rear whole leg removed

further otsverlivaetsya inner arch. remnants of parts waiting for better times.

Originally, I was advised that the machine is not for sale, and perhaps for a long period of operation. on this occasion I decided to leave the power elements of the body in the plant form, ie does not cut it and cook and otsverlivat all power components and welded them in the factory outlets. With the whole brought sidewall + quarter would have been much easier, but then had to poizvraschatsya okay tie.

gradually removed from the body of the sick elements. all the internal arch of the back, the arrow shows a joint, because of which it amputated.

Align could certainly, but the rear wing of the new will not be (((so at least on the arch update will cut an old tin.

retired

with pre-welded parts otsverlennuyu

That's the way the general form of a car without all the side racks

I cling to the slipway crane and kept going the whole sidewall

below the junction of the sidewall of the control points (leaf with the dimensions seen in the photo). and an indirect confirmation of the fact that his side stands in place are a convergence of points of contact regime otsverlennyh me welding (marked with red arrows)

any further welded amplifiers. all points on the factory))

I treat the weld anticorrosive primer, as after installation of the wing will make it problematic.

view from cabin after welding

antikorm handled every

Rear arch inner side

front desk after welding

it after upgrading)

could of course be removed from the sidewall peel some amplifiers and put them in exchange damaged. but so much easier. First save the entire lower basket with both racks with amplifiers in the plant as in the second hell then someone dokapalis sidewall that changed and third most important welding pominimumu.

Then you can move on to the top sheet, ie, piece rear wing.

since the new wing is not planned (very long to explain why))), will be one of the two mold. remember what it was.

come to the aid of the instruments of PDR, simply put mushrooms kleeym) rear rack must say I have prepared in advance.

further put the peel, which was previously otsverlena of parts. Many hope to understand why I did otsverlival.

It boils finally, at long intervals, so that the iron from the welding heat is not led.

That's the way a pile of iron left over from repair

Further machine goes into preparation. Unfortunately I'm not prepared for it, so no pictures. only managed to do))

but the report goes on, since I painted this car)))

after preparation and primer to drive to the car wash, to wash off all the dust

special attention to the painting is not sharpened, longer paid disguise. If that question;)

at the beginning of masking always first place not to be sealed with adhesive tape color, so more precise turns, than later with paper or pieces ukryvki mold. tight bends or narrow areas are sealed nakroynyak contour tape. often come across a car where you have to mask the glass with a rubber molding, with a simple tape can be busy for a long time, comes to the aid is such garbage from 3M

a closer look shows how rising molding. Paint flies under the gum, and then accurately nor any delamination is not molding and not be painted.

Well on tape as the ranshe wrote

and paper

paper the way made it a rule to glue a very long time, since the film is sometimes come off a piece stuck in the base is not the most appropriate time & gt;: D

openings in the paper do not accidentally slammed with cabin secured stretching

the remaining surface, located far from a simple gun hiding ukryvochnoy film.

silver color, very nasty after Pearl, so I paint the same pistol how colorist worked. All clear on the technology first layer of the second 70% 100% 30% third dusted painted must say glazuritovskoy water

After each layer is drying Dry jets

Varnish, the most beautiful and beloved by me)))

More beauty

raspokoval exit

Then came the work of the assembly fitters. in some moments I pouchavstvoval))

fining the scope of the factory doors vinill film type.

glue all around the plant, even with zagibmi.

This kind of the opposite frame factory

far view

any nakleechki

Now in place

Well, the last 4 pictures

time

Two

Three

four. You can zapinyvat)))

Source: