1928

Construction of the jet boat on the basis of Zarephath

The idea to make the jet boat stuck in the brain for a long time, but not the time came to implement this scheme.

Key to the boat Wishlist:

1. The jet engine of a stationary engine

2. cabin with beds at least 3 people.

3. Passenger capacity 5 people, plus space for shmurdyak, including a set of PVC with a motor.

54 photos

On the occasion I turned up almost new (never on the water was not) body of Prgress-2MR. Internet broke the brain in half. On the one hand Progress-2M - iron, which scour the wave, on the other hand, all treated or alteration of housing gidroshayboy. In any case, we had only the bottom, the rest is all planned to do on their own.

One of the problems that will arise in the future, was the absence of the trailer, the price tag of 50 sput. exceeded the psychological limit of the price of a similar piece of iron.

As the engine to the boat selected toyotovskie engine 5E, which is around collecting dust in a service garage and required little maintenance. The engine has been sent in for repair.

After studying on the Internet by water jets, the choice fell on Minusinsky water cannon.

At the last moment before the start of work on the horizon appeared Sarepta in more or less good condition, so even with a trailer. There was no hesitation - the next day Sarepta migrated to a makeshift shipyard to advertise the sale of Progress has hung a couple of days - the buyer was found immediately.

Work began with the removal of all that can be removed and analysis of everything that can be disassembled.

There were milestones:

1. Push the stationary cabin forward 30 cm. With the dismantling of the control console

2. Increase the length of the cabin to normal human growth meter ninety.

3. To increase the overall length of the boat by 60 centimeters for larger payload and usable volume, which drastically reduced due to the installation, and stationary jet engine.

4. Move the steering place of the cabin fresh air.

5. Increase the width of the boards

6. Strengthen the side and bottom.

In order to strengthen the bottom unconditionally selected 10mm UHMWPE (UHMWPE) after watching the following video:

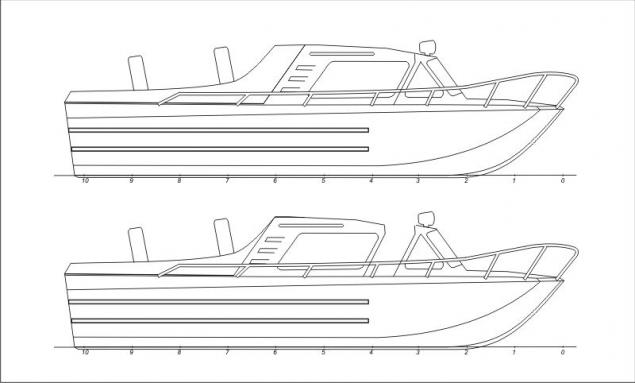

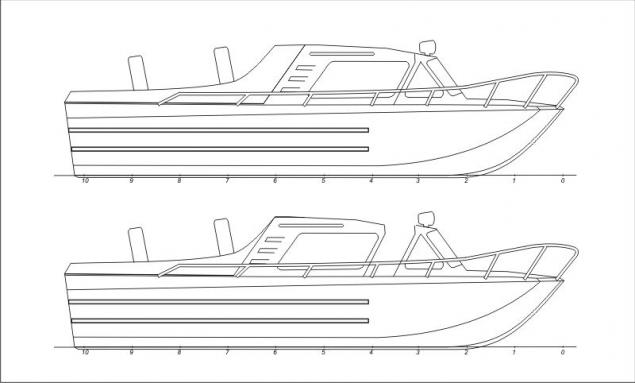

Preliminary sketch of the future boat on a scale collected from Internet photos

dismantled windscreen frame, marked a new installation location and it was the turn grinders. Cut out the console and the console of the partition at floor level. On top of the nose cut off all the excess, leaving only the stiffener. Cut off all unnecessary and aft. Remove all blocks unsinkable mercilessly battered by time and moisture. Dismantling over. It is time of creation ...

Preliminary design of the boat drew Anton Semenov, he's a southpaw worked (at the time he painted the album cover for infektet mashrumz). Unfortunately, 100% design bring to life does not work, but try to make the most of it seems :)

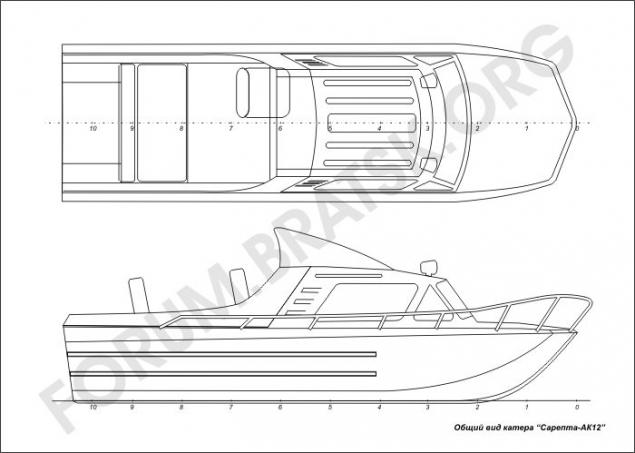

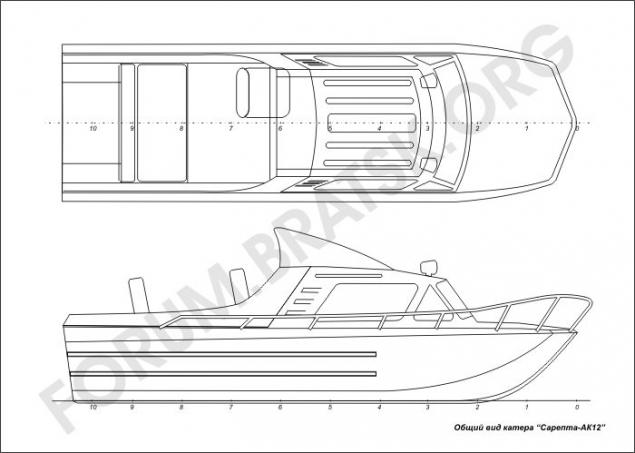

Preliminary general drawing.

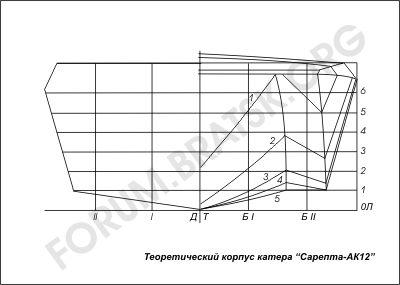

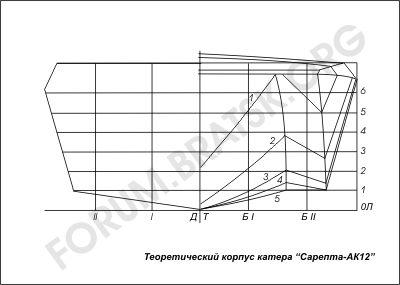

Drawing boats sectional

development view

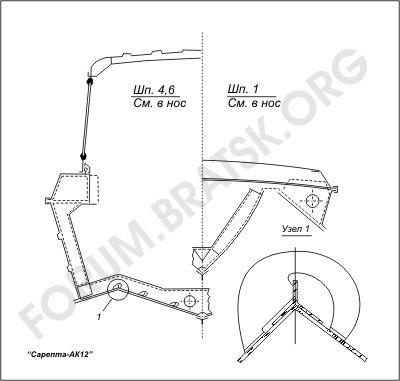

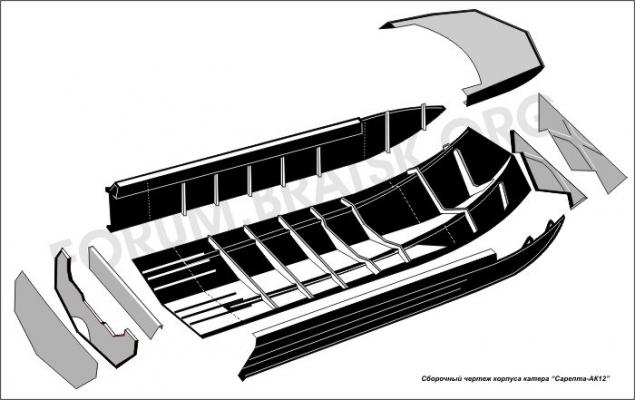

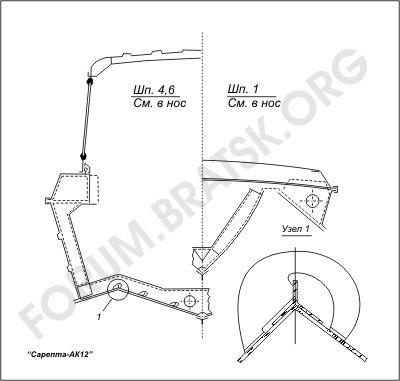

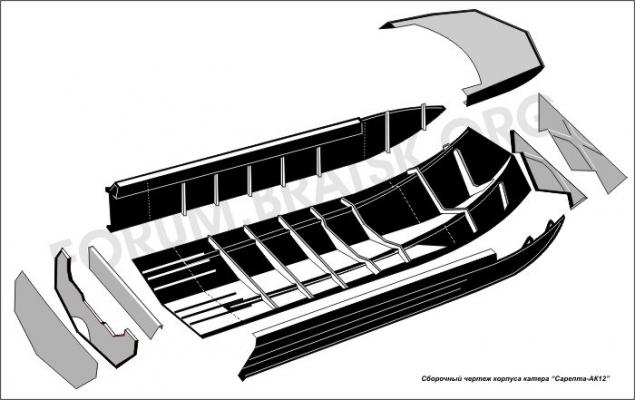

and an assembly drawing

Posted in [mergetime] 1371051275 [/ mergetime]

Ordered Turbofan cooled exhaust manifold of stainless steel, double-oil cooler and a heat exchanger for cooling the gasoline engine 75 to 200 hp Seawater (stainless steel heat exchanger copper pipe) cooling surface area of 45,200 sq cm.

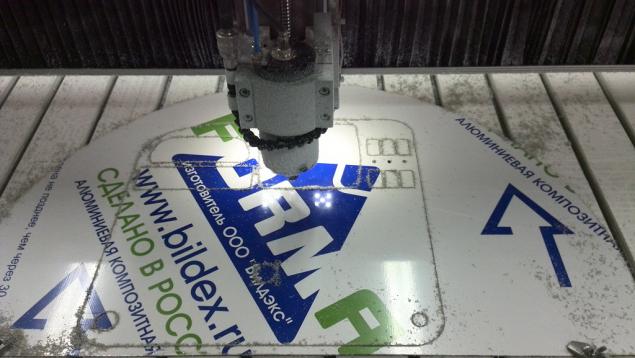

After some deliberation, we decided to lengthen in a production environment.

Making pile

The process has started ...

The process has started ...

The process has started ...

Maestro at work

Welding long look, harmful to the eyes :)

The sub-frame

Baki decided to do the floor.

Three pieces, each with a volume of about 45 liters, 1.2 mm

chernyashka

While the process of lengthening the body and the manufacture of tanks, gradually began to take shape cockpit.

Cdvizhnaya roof has an additional extension that is rigidly fixed to the boat and the partition of course. The roof if necessary (for ventilation, look out) moves back over a limited distance (the figure is 300 mm) and rests against the fence. The edge extension, it does not go away.

Perhaps the shift width will be increased.

A spine to rest not beat, do automatically latch

Theoretically it looks like this:

Work on lengthening and strengthening of the boat engine compartment come to an end.

Ready to take the boat out of the shop.

Ready to aft platform.

Ready to aft platform.

Ready to aft platform.

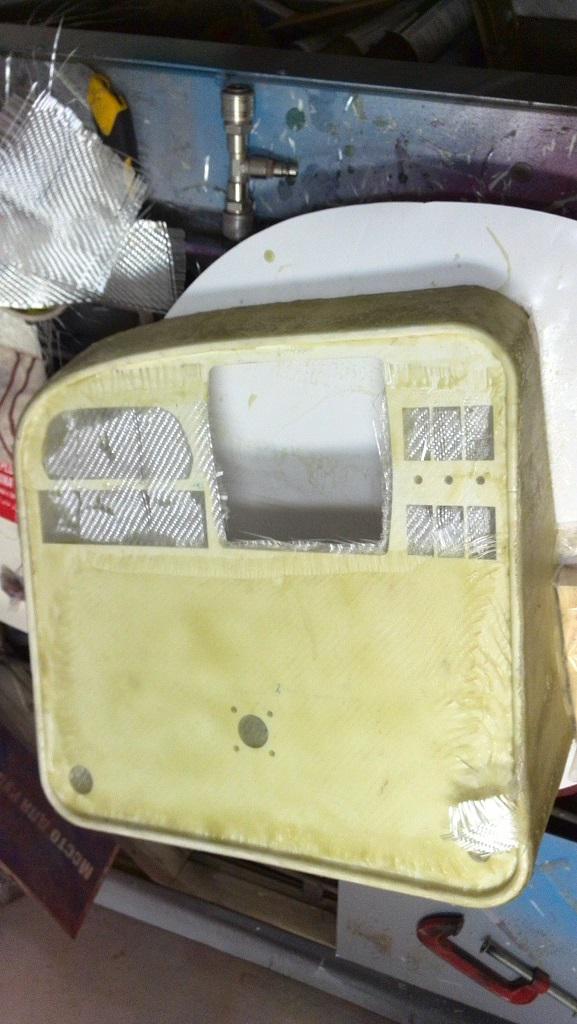

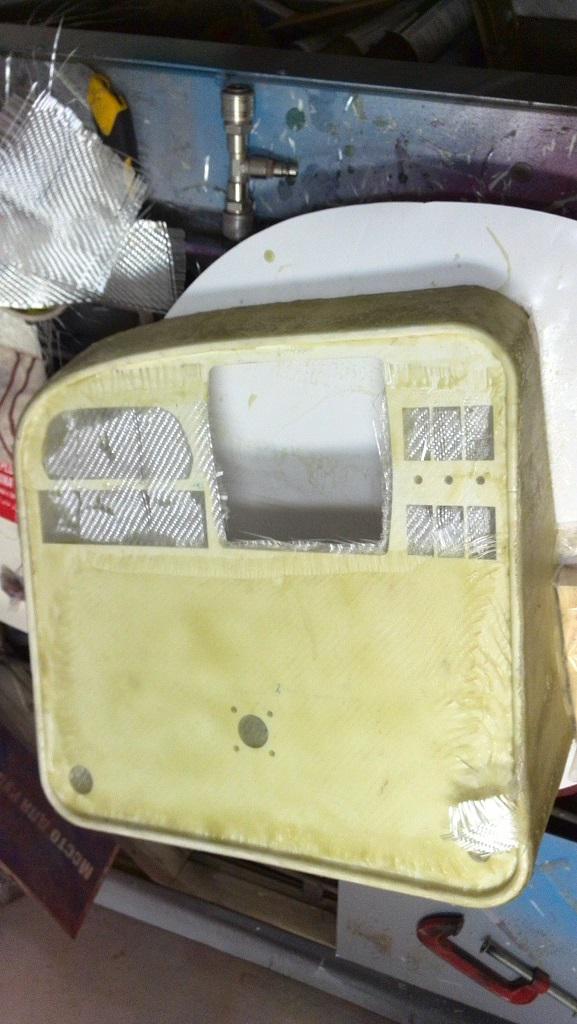

In his southpaw began to make the podium for the control panel.

Base - PVC plastic, fiberglass cloth over it with a resin.

They removed the old paint using washing body 500. It took 4 banks. Wash in green glass bottles - of money - has not worked.

After removing the paint three liters of wash solvent, a roll of cloth. Then, two bottles of degreaser type Nefras.

4 bottles of Raptor, for the anti-gravity spray gun, compressor and a little time. Veils on twice.

Live, looks pretty good. Get rid of technological defects Zarephath using a monochromatic ink is not quite possible, but I'm happy with the result.

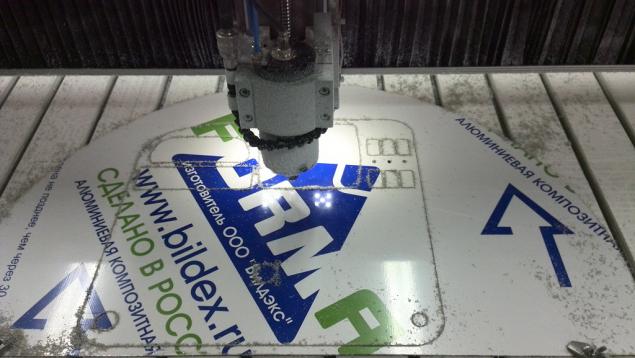

We impose two major pieces of UHMWPE. Drill all, zazenkovali.

The floor is ready. Dartveyder rather than the bottom :)

The bottom mounted on the sealant. Sealant though not spared, but the excess around the edges to squeeze quite a bit. It took 11 600-gram sausage sealant 3M PU 550, 5 hours without six of fitting plates. We tried to do everything at once, so that the sealant on the joints did not have time to harden and formed a homogeneous mass.

Building management console.

Building management console.

Building management console.

Building management console.

Building management console.

Made frame walls and most of the cabin.

Mud filter and winch took their seats.

Winch had to modify - shorten the handle and replace the handle on the more compact.

Gathered under the sub-frame extension board, polystyrene foam to fill the void. Gone 1200h600h50 sheet and sheet 1200h600h35

Blocks of flooding in the bow, a gain on the bow deck.

Trays of sewing beads.

To soothe the conscience tried to drown a piece of UHMWPE in a mug of water. Naturally it failed. Additional buoyancy boat probably has not increased, but their weight compensates - and the bread.

The process of filling the buoyancy blocks ...

The process of filling the buoyancy blocks ...

Mount the motor in place. To install a sensor in the reservoir and oily cooler had deformed oil filters. Output from the collector had also digesting - or not to put the hose on him.

It does not quite understand the logic of the production minusintsev cooler bypass (inlet and outlet water 20), and exhaust manifold (pipe 16).

While water pipes were distributed as follows:

1 - water jet - Filter - oily cooler - the exhaust manifold - dyurit

2 - water cannon - filter - double-cooler - dyurit

Engine ...

Engine ...

BMX powered from the stove. We did exhaust. Stitched nose trays of riveted wind frame. Installed on the perimeter fender. Collected partition and tried on the control panel. Well, on the little things - embedded fuel neck, consolidated unit relays and fuses, cut blocks of buoyancy ...

More ...

More ...

Lots of little things, the process is slow. Prepared to cover sofas and lockers, cut and assembled blocks of 3 layers of 10 mm foam, cutting leatherette. Painted in black raptor forepeak, cabin roof is lined, reinforced, Align, and covered with white raptor outside. It looks gorgeous. Glass from 4mm solid polycarbonate toned American (5% black side, frontal 10% black). UHMWPE cut fairlead and placed on the sealant. Roulz the anchor come Monday. bent and riveted in place nasal handrails. Set the throttle, prokinut rope. Mounted handbrake on reversing valve, wire rope prokinut up the middle. From inside the bucket wound former steering cable. The panel is removed and sent to a painting. The lockers are cut keel laying of the polycarbonate to every small things in the gap between frames and fuel tank does not leak. There are thoughts progermetit it ends polyurethane sealant - additional blocks of buoyancy will come.

Well, today, May 4, 2013 opening of the hunting. It was decided to commemorate the opening of the hunting Zarephath descent into the water. In the morning we gathered in the garage and work started. Many more had to finish before launching. In the fourth floor dragged the boat onto the trailer and rolled out into the street. They poured 60 liters of benzyl and rushed to Angara.

Driving past the truck scales have noticed that they are working. Asked to weigh in - 600 kg with trailer and 60 liters of benzyl. Trailer 220 on the passport, plus benzo 40. Total net weight of the boat 340 kg.

The first launch ended in a fiasco - when fully raised bucket reverse steering damper when turning to right clinging to the spade reverse and the boat could only go right or left. And left us can not - married. Had priopustit flap.

Video here:

The second problem with multitroniksom climbed. In no regime did not want to define engine electronics, a universal nifiga not show. Accordingly, no momentum, no engine temperature were not available ... Plus the care multitroniksa to shut-in the uncertainty lights companies chek, slightly negative effect on the nerves.

The third problem in the exhaust manifold. Top reservoir of ice.

The water coming out of the exhaust pipe a little warm. But the pipe between the collector and fittings dyurita already at the middle (the sound) speed is heated so that they begin to burn hoses that are nearby.

On the other byada hoses. As I understand it, I did not minusintsy steamed by the fact that this engine conversion they did and cooked they are used to - for engines in which the exhaust manifold on the right. And 5E he left, all connections are deployed all turned in the opposite direction, some hoses had to bend 180 degrees, part of the trace around the engine. And about the way the steering lever in the manufacture of jet would do well to clarify at the customer location helm - I wheel to the left, like a true European, and the lever is designed for right-hand drive vehicles. It was necessary to expand it to 180 degrees and it barely barely squeezed along the conduit between the body and exhaust hose.

The fourth flaw - not quite guess with trim - you need to change the length of a bit of traction - enough to travel.

Videos in one gas given on 1/2

A little confused wake. Video 2/3 gas threesome

Source:

Key to the boat Wishlist:

1. The jet engine of a stationary engine

2. cabin with beds at least 3 people.

3. Passenger capacity 5 people, plus space for shmurdyak, including a set of PVC with a motor.

54 photos

On the occasion I turned up almost new (never on the water was not) body of Prgress-2MR. Internet broke the brain in half. On the one hand Progress-2M - iron, which scour the wave, on the other hand, all treated or alteration of housing gidroshayboy. In any case, we had only the bottom, the rest is all planned to do on their own.

One of the problems that will arise in the future, was the absence of the trailer, the price tag of 50 sput. exceeded the psychological limit of the price of a similar piece of iron.

As the engine to the boat selected toyotovskie engine 5E, which is around collecting dust in a service garage and required little maintenance. The engine has been sent in for repair.

After studying on the Internet by water jets, the choice fell on Minusinsky water cannon.

At the last moment before the start of work on the horizon appeared Sarepta in more or less good condition, so even with a trailer. There was no hesitation - the next day Sarepta migrated to a makeshift shipyard to advertise the sale of Progress has hung a couple of days - the buyer was found immediately.

Work began with the removal of all that can be removed and analysis of everything that can be disassembled.

There were milestones:

1. Push the stationary cabin forward 30 cm. With the dismantling of the control console

2. Increase the length of the cabin to normal human growth meter ninety.

3. To increase the overall length of the boat by 60 centimeters for larger payload and usable volume, which drastically reduced due to the installation, and stationary jet engine.

4. Move the steering place of the cabin fresh air.

5. Increase the width of the boards

6. Strengthen the side and bottom.

In order to strengthen the bottom unconditionally selected 10mm UHMWPE (UHMWPE) after watching the following video:

Preliminary sketch of the future boat on a scale collected from Internet photos

dismantled windscreen frame, marked a new installation location and it was the turn grinders. Cut out the console and the console of the partition at floor level. On top of the nose cut off all the excess, leaving only the stiffener. Cut off all unnecessary and aft. Remove all blocks unsinkable mercilessly battered by time and moisture. Dismantling over. It is time of creation ...

Preliminary design of the boat drew Anton Semenov, he's a southpaw worked (at the time he painted the album cover for infektet mashrumz). Unfortunately, 100% design bring to life does not work, but try to make the most of it seems :)

Preliminary general drawing.

Drawing boats sectional

development view

and an assembly drawing

Posted in [mergetime] 1371051275 [/ mergetime]

Ordered Turbofan cooled exhaust manifold of stainless steel, double-oil cooler and a heat exchanger for cooling the gasoline engine 75 to 200 hp Seawater (stainless steel heat exchanger copper pipe) cooling surface area of 45,200 sq cm.

After some deliberation, we decided to lengthen in a production environment.

Making pile

The process has started ...

The process has started ...

The process has started ...

Maestro at work

Welding long look, harmful to the eyes :)

The sub-frame

Baki decided to do the floor.

Three pieces, each with a volume of about 45 liters, 1.2 mm

chernyashka

While the process of lengthening the body and the manufacture of tanks, gradually began to take shape cockpit.

Cdvizhnaya roof has an additional extension that is rigidly fixed to the boat and the partition of course. The roof if necessary (for ventilation, look out) moves back over a limited distance (the figure is 300 mm) and rests against the fence. The edge extension, it does not go away.

Perhaps the shift width will be increased.

A spine to rest not beat, do automatically latch

Theoretically it looks like this:

Work on lengthening and strengthening of the boat engine compartment come to an end.

Ready to take the boat out of the shop.

Ready to aft platform.

Ready to aft platform.

Ready to aft platform.

In his southpaw began to make the podium for the control panel.

Base - PVC plastic, fiberglass cloth over it with a resin.

They removed the old paint using washing body 500. It took 4 banks. Wash in green glass bottles - of money - has not worked.

After removing the paint three liters of wash solvent, a roll of cloth. Then, two bottles of degreaser type Nefras.

4 bottles of Raptor, for the anti-gravity spray gun, compressor and a little time. Veils on twice.

Live, looks pretty good. Get rid of technological defects Zarephath using a monochromatic ink is not quite possible, but I'm happy with the result.

We impose two major pieces of UHMWPE. Drill all, zazenkovali.

The floor is ready. Dartveyder rather than the bottom :)

The bottom mounted on the sealant. Sealant though not spared, but the excess around the edges to squeeze quite a bit. It took 11 600-gram sausage sealant 3M PU 550, 5 hours without six of fitting plates. We tried to do everything at once, so that the sealant on the joints did not have time to harden and formed a homogeneous mass.

Building management console.

Building management console.

Building management console.

Building management console.

Building management console.

Made frame walls and most of the cabin.

Mud filter and winch took their seats.

Winch had to modify - shorten the handle and replace the handle on the more compact.

Gathered under the sub-frame extension board, polystyrene foam to fill the void. Gone 1200h600h50 sheet and sheet 1200h600h35

Blocks of flooding in the bow, a gain on the bow deck.

Trays of sewing beads.

To soothe the conscience tried to drown a piece of UHMWPE in a mug of water. Naturally it failed. Additional buoyancy boat probably has not increased, but their weight compensates - and the bread.

The process of filling the buoyancy blocks ...

The process of filling the buoyancy blocks ...

Mount the motor in place. To install a sensor in the reservoir and oily cooler had deformed oil filters. Output from the collector had also digesting - or not to put the hose on him.

It does not quite understand the logic of the production minusintsev cooler bypass (inlet and outlet water 20), and exhaust manifold (pipe 16).

While water pipes were distributed as follows:

1 - water jet - Filter - oily cooler - the exhaust manifold - dyurit

2 - water cannon - filter - double-cooler - dyurit

Engine ...

Engine ...

BMX powered from the stove. We did exhaust. Stitched nose trays of riveted wind frame. Installed on the perimeter fender. Collected partition and tried on the control panel. Well, on the little things - embedded fuel neck, consolidated unit relays and fuses, cut blocks of buoyancy ...

More ...

More ...

Lots of little things, the process is slow. Prepared to cover sofas and lockers, cut and assembled blocks of 3 layers of 10 mm foam, cutting leatherette. Painted in black raptor forepeak, cabin roof is lined, reinforced, Align, and covered with white raptor outside. It looks gorgeous. Glass from 4mm solid polycarbonate toned American (5% black side, frontal 10% black). UHMWPE cut fairlead and placed on the sealant. Roulz the anchor come Monday. bent and riveted in place nasal handrails. Set the throttle, prokinut rope. Mounted handbrake on reversing valve, wire rope prokinut up the middle. From inside the bucket wound former steering cable. The panel is removed and sent to a painting. The lockers are cut keel laying of the polycarbonate to every small things in the gap between frames and fuel tank does not leak. There are thoughts progermetit it ends polyurethane sealant - additional blocks of buoyancy will come.

Well, today, May 4, 2013 opening of the hunting. It was decided to commemorate the opening of the hunting Zarephath descent into the water. In the morning we gathered in the garage and work started. Many more had to finish before launching. In the fourth floor dragged the boat onto the trailer and rolled out into the street. They poured 60 liters of benzyl and rushed to Angara.

Driving past the truck scales have noticed that they are working. Asked to weigh in - 600 kg with trailer and 60 liters of benzyl. Trailer 220 on the passport, plus benzo 40. Total net weight of the boat 340 kg.

The first launch ended in a fiasco - when fully raised bucket reverse steering damper when turning to right clinging to the spade reverse and the boat could only go right or left. And left us can not - married. Had priopustit flap.

Video here:

The second problem with multitroniksom climbed. In no regime did not want to define engine electronics, a universal nifiga not show. Accordingly, no momentum, no engine temperature were not available ... Plus the care multitroniksa to shut-in the uncertainty lights companies chek, slightly negative effect on the nerves.

The third problem in the exhaust manifold. Top reservoir of ice.

The water coming out of the exhaust pipe a little warm. But the pipe between the collector and fittings dyurita already at the middle (the sound) speed is heated so that they begin to burn hoses that are nearby.

On the other byada hoses. As I understand it, I did not minusintsy steamed by the fact that this engine conversion they did and cooked they are used to - for engines in which the exhaust manifold on the right. And 5E he left, all connections are deployed all turned in the opposite direction, some hoses had to bend 180 degrees, part of the trace around the engine. And about the way the steering lever in the manufacture of jet would do well to clarify at the customer location helm - I wheel to the left, like a true European, and the lever is designed for right-hand drive vehicles. It was necessary to expand it to 180 degrees and it barely barely squeezed along the conduit between the body and exhaust hose.

The fourth flaw - not quite guess with trim - you need to change the length of a bit of traction - enough to travel.

Videos in one gas given on 1/2

A little confused wake. Video 2/3 gas threesome

Source: