603

Magnetic contacts

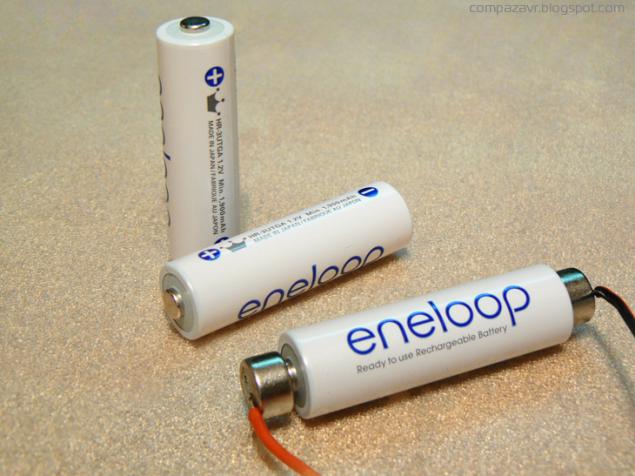

We charge the batteries, which do not understand how to connect to the charger.

9 photo

I once again took charge the lithium battery flashlight. Despite the fact that the item has a standard size (18650) - the container for it was not. Universal Charger is, but the container is not! Have primatyvat to the battery contacts with soldered wires and in such a way to connect to it charger.

I decided that it was time to attend to and do something more reusable. Especially in the arsenal already bred batteries and other sizes.

Came unexpectedly even for myself the idea of using neodymium magnets, dally:

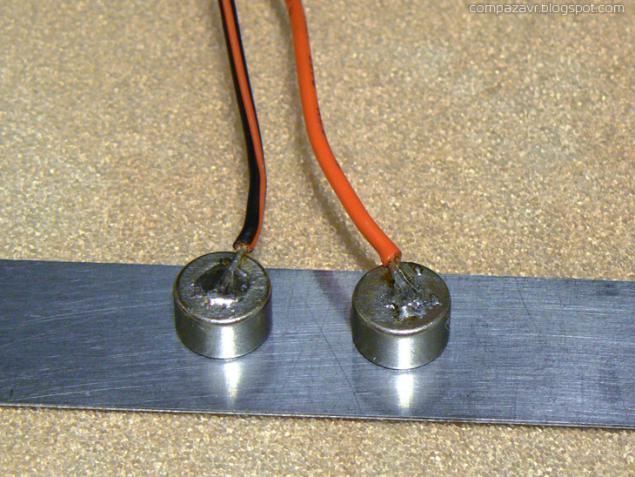

They are very well kept on the metal contacts on the battery and the surface is covered with some kind of metal, much like a conventional chrome plating. It has a low electrical resistance, and it is easy to bear the normal solder:

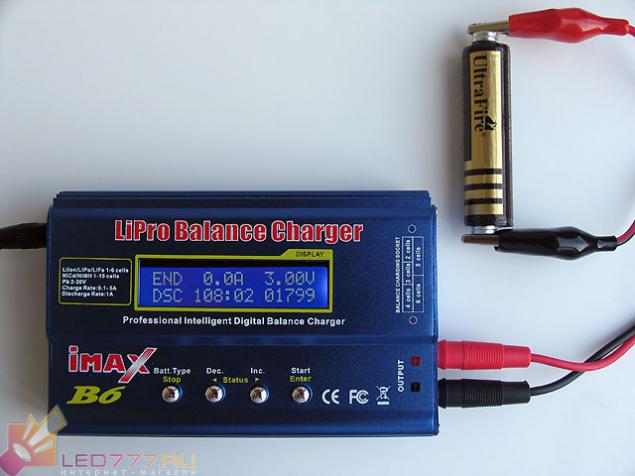

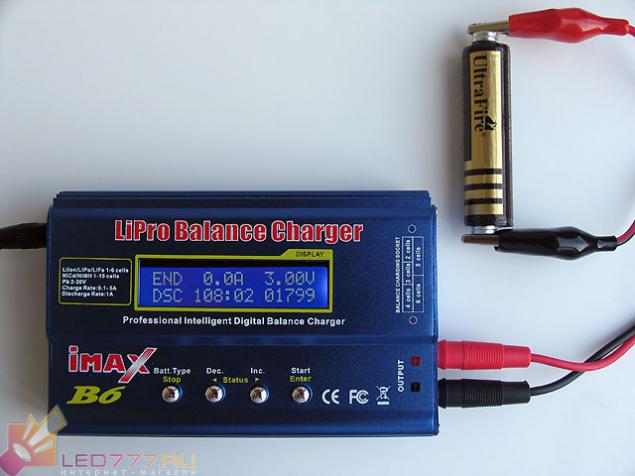

Magnets soldered to the terminal block, connected to the memory, prischёlknul magnets to the contacts of the battery and the charging process went:

Sami magnets during the charging time is not warmed up, indicating that a sufficient contact area and low resistance.

In this way, user-friendly display contacts with the battery of any size, as long as he had a terminal of metal, interacts with a magnet.

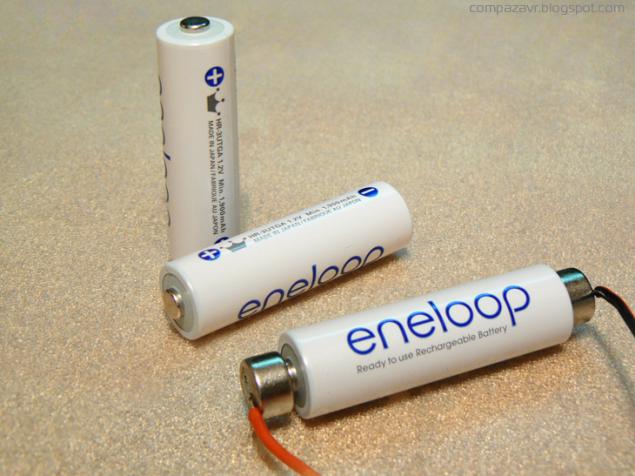

Also with the help of such magnets can collect multiple items in the battery:

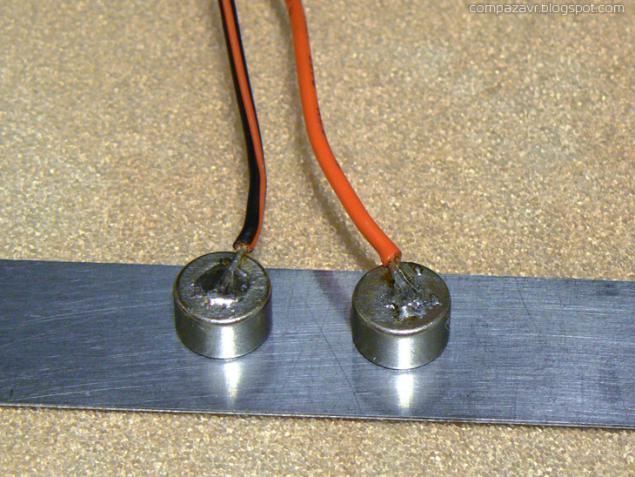

The wires should be soldered to the poles of the magnets of the same name that do not have them then forcibly tear, hook the smooth sides. Or as an alternative - to keep them on the segment of the metal strip:

All the photos where the magnets are close to each other and do not interact with each other - a photomontage. Be careful: Neodymium magnets are very strong and can cause injury by careless handling.

But all you can do without soldering and pull the metal contacts with soldered wires to magnets:

Source:

9 photo

I once again took charge the lithium battery flashlight. Despite the fact that the item has a standard size (18650) - the container for it was not. Universal Charger is, but the container is not! Have primatyvat to the battery contacts with soldered wires and in such a way to connect to it charger.

I decided that it was time to attend to and do something more reusable. Especially in the arsenal already bred batteries and other sizes.

Came unexpectedly even for myself the idea of using neodymium magnets, dally:

They are very well kept on the metal contacts on the battery and the surface is covered with some kind of metal, much like a conventional chrome plating. It has a low electrical resistance, and it is easy to bear the normal solder:

Magnets soldered to the terminal block, connected to the memory, prischёlknul magnets to the contacts of the battery and the charging process went:

Sami magnets during the charging time is not warmed up, indicating that a sufficient contact area and low resistance.

In this way, user-friendly display contacts with the battery of any size, as long as he had a terminal of metal, interacts with a magnet.

Also with the help of such magnets can collect multiple items in the battery:

The wires should be soldered to the poles of the magnets of the same name that do not have them then forcibly tear, hook the smooth sides. Or as an alternative - to keep them on the segment of the metal strip:

All the photos where the magnets are close to each other and do not interact with each other - a photomontage. Be careful: Neodymium magnets are very strong and can cause injury by careless handling.

But all you can do without soldering and pull the metal contacts with soldered wires to magnets:

Source: