931

Unique profession.

Our heroes today call themselves happy, because what he likes. To some it may seem extravagant, as citizens of Minsk Viktor Shevtsov and Konstantin Dudarev not carry clothes from Moscow, and ... made armor. About an unusual profession, orders, prices, collectors and vocation - in our material.

34 photo and text source.

The workshop, staffed by Victor and Constantine, located on the outskirts of Minsk. Average room: hammers, tools, screwdriver. Only in the center - a knight's armor worth more than $ 20 thousand. And on the walls - shields and helmets.

Gunsmiths of the XXI century talk about why decided to do unusual for Belarus business.

Gunsmiths of the XXI century talk about why decided to do unusual for Belarus business.

Constantine: It all started in early adolescence. We are fond of chivalric movement, historical reconstruction. I am a sculptor, he graduated from the Academy of Arts. Victor - Welding Engineer. At first we were made armor for themselves, helped soklubnikam, and then decided to work professionally. In 2004, we organized a workshop entitled "Steel Heritage».

Konstantin Dudarev

Victor: At first it was kind of an experiment. We stayed in the main job, and in the evenings, on weekends to find time and fulfill orders. When he felt the ground under his feet, there was a confidence that we can provide for themselves, resigned and engaged exclusively armor. Bought the necessary tools, equipment, launched the site. Send orders from abroad - from America, Europe and the Middle East. One of our customers was the president of the All-Russian military-historical movement. A source of pride - orders for Belarusian historical museums. We were able to make armor for Mir and Nesvizh castles. This was largely after mastered the technology of aging metal. Museums do not need ground and polished armor, they need the exhibits related to the historical maximum.

Viktor Shevtsov

Constantine: Mir Castle for we have made a large arsenal. Many have probably seen our winged hussar armor. There were many projects and Nesvizh. Then there was a devaluation, Nesvizh Castle, unfortunately, reduced funding.

Hussar armor Rzeczpospolita, the first half of the XVII century

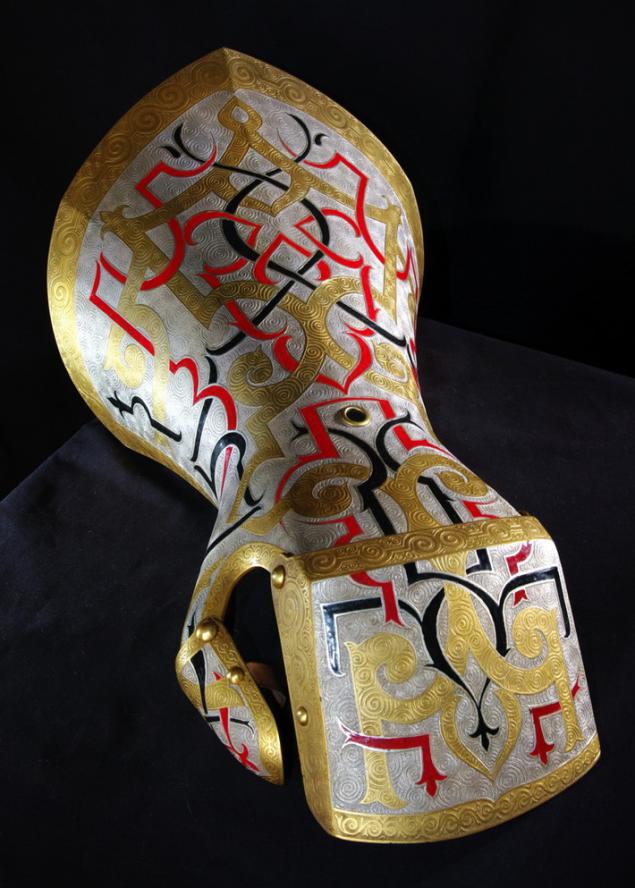

Victor: We, if you can call it, the ideological work - manifera recreation, protective gauntlet Radziwill the Black. Preserved only parts of the armor, which is considered one of a kind. These disparate elements are kept in museums in New York, Vienna and Paris. We have one item that is considered lost - the gauntlet for horse fights. It is known that the set produced for the Radziwill Master Kunz Lochner. We found preserved armor of the wizard, in his model to withstand the style made manifer. It also acquired the Mir Castle.

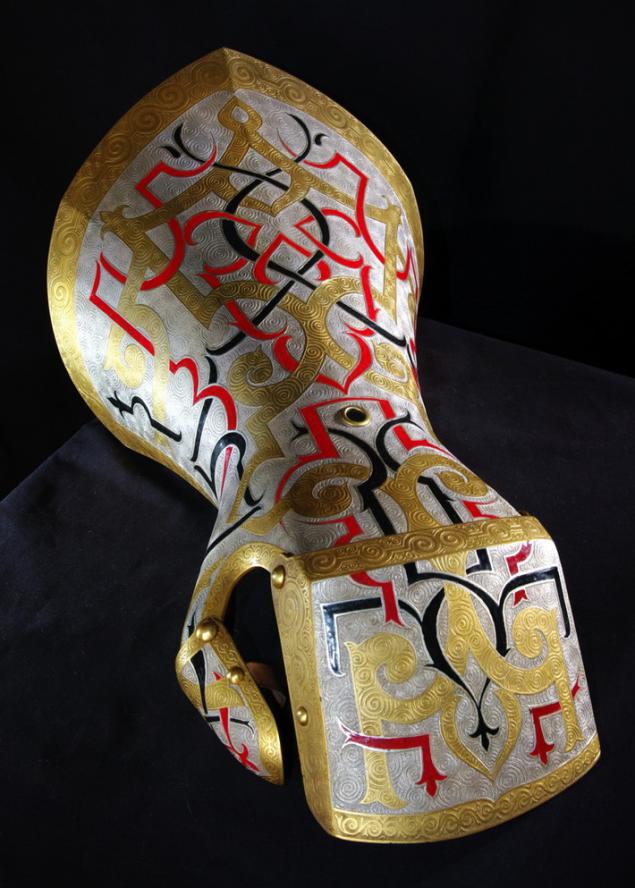

Tournament manifer from the front headset Radziwill Black, 1555

To all this must be

Victor: As such, the market in Belarus. Rather, the market today is not the republican and international. We have to compete not with Belarus and with masters from around the world.

Constantine: Speaking for whom we work, it's not exactly re-enactors. Rare people in Belarus can afford to order such a thing, then to go to them in the battle. Among the major customers, in addition to the museums - collectors. It is unlikely that any of them will use the armor for its intended purpose - rather, they were put in a room in a prominent place. Still, customers want everything to work, dress up, the approach was functional. We had an order from the largest collector and the east coast of the United States - is also a reason for pride.

Check for a rich American collector

Gothic armor, XV century. It made for the president of the All-Russian military-historical social movement

Designers of steel

- For example, the customer asks you to make armor period of the Battle of Grunwald. How to start work?

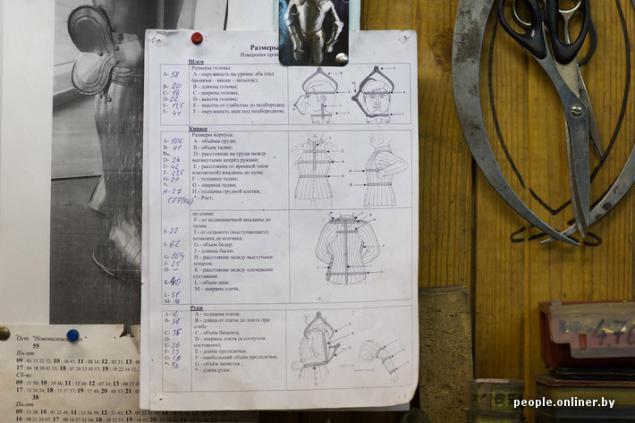

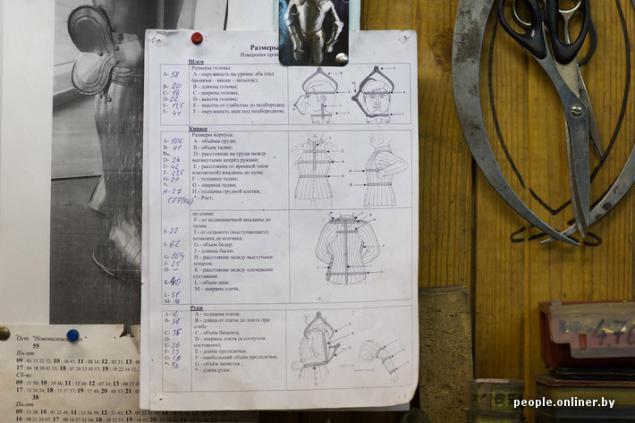

Victor: We choose a specific pattern that people want to get. Completely remove from the customer's size. In fact, we are working as usual fashion. Photographing the client a full-length photograph in the head face and profile. Then draw a sketch on paper. We draw all the elements of all proportion. Next, remove the pattern and have been working in the sheet metal: the hot or cold. Stamping, propilovka - there is plenty of technological highlights. Something to forge something sometimes weld.

Punching holes in the skin

***

***

***

Constantine: In the process of work a person can see how the armor will sit on his figure. Often, the customer is itself some ammunition Gothic style, but his beer belly. We try to make the product looked aesthetically pleasing, beautiful.

Year to work

Constantine: Armor, which now stands in our workshop - obraztsa1530 year. This German armor postmaksimilianovskoy era or early Renaissance. He ordered a Minsk businessman, history buff. Over this year we worked armor!

Plate armor Maximilian period. Shoes as a "bear paws". Used for equestrian combat. Virtually invincible, if one is well prepared. Opponents tried to hit the knight in the underarm, cut back the tendon or stab into the slot helmet

The helmet weighs about 5 kg

The smallest attention to detail - an indispensable attribute of any high-quality armor. In fact, it is a work of art

***

***

One of the signs, amulets, which were applied to armor

Victor:

If we talk about simple armor, the shortest period of time for which you can handle - 4-5 months. If we work together.

***

Constantine:

In medieval armor evolved regularly, every 20-30 years. End of XIV - early XV centuries - early Gothic, quite simple in form armor, many elements of the chain mail. But the armor completely covers the body of the soldier. At the end of the XV century appeared graceful lines, edges, reminiscent of water ripples. In the future, technology perfected, the metal becomes thinner and armor - lighter.

Milan armor, XV century

Harvesting of early medieval helmet

Bib and naspinnik gothic breastplate end of the XV century

About props

- If you could send a customer, a businessman in your armor on a medieval battlefield, how quickly would he parted with life?

Victor: It all depends on his combat training! And on armor will be tempered or not. In other words, whether the customer is willing to pay for real combat, working armor. If so, then he will be no worse than they did a few centuries ago. Modern steel is largely allows the armor harder.

- Speaking of weight, an untrained person can feel comfortable, dressed in steel?

Victor

: From what we were doing was the heaviest armor weighing 35-40 kilograms. If done correctly, this can absolutely wear any man, not necessarily an athlete. Weight is distributed throughout the body, he will not hang around his neck like a weight. Another thing, what actions a "knight" will be able to perform.

Italian armor of the middle of the XVI century

- Modern masters to work much better than a medieval?

Constantine

: Of course, in the XVI century, it was different. But in many ways it is now more difficult to us. Then the work was knotted and skills handed down from generation to generation. And masters made armor in the fashion of his time, and we do the armor of various periods. In later centuries, the skill has been largely lost since the need for armor disappeared. As a result, we now have to come up with some things over again, wondering: how it was with them? As for tools, in this respect, of course, we have easier. We do not need horns and medieval methods of cutting, there are grinders, machine tools, electric welding.

- By the way, what kind of activities carried your profession Belarusian officials?

Constantin: Of course, this kind of activity in the register of the Republic of Belarus was not there. Therefore, the registration issued as "activity in the field of art».

Shishak sample of XVII century during assembly

Template for making visor early XV century

Template for iron shoes

***

Armor for rats sometimes allow themselves masters and joke

Salaries and creativity

Victor

: When calculating the cost of a product, we try to succeed by earning at least $ 600 per person per month. That's the minimum. We aim to come to a salary of $ 1,000. Most goes somewhere.

Constantine

: Lay not get more interesting figures: in this case the armor would be difficult to sell. In Belarus, very few people willing to pay the same $ 20 thousand. For the product, which is not less than a year.

Victor:

We do not work solely on salary, to make faster and faster to collect money. We try to make the final product came out in something perfect. If you see some nuances, it is better to change, ask the customer to wait. The question of prestige, image, if you want. As for salaries, then, the feelings, a blacksmith who makes stairs earns more than we do.

Constantine:

The forging business repelled from $ 1,000, we leave this figure does not always. But even this is not important. We do not do routine work, from which the tired psychologically. Just the opposite.

It's pure creativity, which is fun for us and our customers.

that's all, thank you for your attention

Source:

34 photo and text source.

The workshop, staffed by Victor and Constantine, located on the outskirts of Minsk. Average room: hammers, tools, screwdriver. Only in the center - a knight's armor worth more than $ 20 thousand. And on the walls - shields and helmets.

Gunsmiths of the XXI century talk about why decided to do unusual for Belarus business.

Gunsmiths of the XXI century talk about why decided to do unusual for Belarus business.

Constantine: It all started in early adolescence. We are fond of chivalric movement, historical reconstruction. I am a sculptor, he graduated from the Academy of Arts. Victor - Welding Engineer. At first we were made armor for themselves, helped soklubnikam, and then decided to work professionally. In 2004, we organized a workshop entitled "Steel Heritage».

Konstantin Dudarev

Victor: At first it was kind of an experiment. We stayed in the main job, and in the evenings, on weekends to find time and fulfill orders. When he felt the ground under his feet, there was a confidence that we can provide for themselves, resigned and engaged exclusively armor. Bought the necessary tools, equipment, launched the site. Send orders from abroad - from America, Europe and the Middle East. One of our customers was the president of the All-Russian military-historical movement. A source of pride - orders for Belarusian historical museums. We were able to make armor for Mir and Nesvizh castles. This was largely after mastered the technology of aging metal. Museums do not need ground and polished armor, they need the exhibits related to the historical maximum.

Viktor Shevtsov

Constantine: Mir Castle for we have made a large arsenal. Many have probably seen our winged hussar armor. There were many projects and Nesvizh. Then there was a devaluation, Nesvizh Castle, unfortunately, reduced funding.

Hussar armor Rzeczpospolita, the first half of the XVII century

Victor: We, if you can call it, the ideological work - manifera recreation, protective gauntlet Radziwill the Black. Preserved only parts of the armor, which is considered one of a kind. These disparate elements are kept in museums in New York, Vienna and Paris. We have one item that is considered lost - the gauntlet for horse fights. It is known that the set produced for the Radziwill Master Kunz Lochner. We found preserved armor of the wizard, in his model to withstand the style made manifer. It also acquired the Mir Castle.

Tournament manifer from the front headset Radziwill Black, 1555

To all this must be

Victor: As such, the market in Belarus. Rather, the market today is not the republican and international. We have to compete not with Belarus and with masters from around the world.

Constantine: Speaking for whom we work, it's not exactly re-enactors. Rare people in Belarus can afford to order such a thing, then to go to them in the battle. Among the major customers, in addition to the museums - collectors. It is unlikely that any of them will use the armor for its intended purpose - rather, they were put in a room in a prominent place. Still, customers want everything to work, dress up, the approach was functional. We had an order from the largest collector and the east coast of the United States - is also a reason for pride.

Check for a rich American collector

Gothic armor, XV century. It made for the president of the All-Russian military-historical social movement

Designers of steel

- For example, the customer asks you to make armor period of the Battle of Grunwald. How to start work?

Victor: We choose a specific pattern that people want to get. Completely remove from the customer's size. In fact, we are working as usual fashion. Photographing the client a full-length photograph in the head face and profile. Then draw a sketch on paper. We draw all the elements of all proportion. Next, remove the pattern and have been working in the sheet metal: the hot or cold. Stamping, propilovka - there is plenty of technological highlights. Something to forge something sometimes weld.

Punching holes in the skin

***

***

***

Constantine: In the process of work a person can see how the armor will sit on his figure. Often, the customer is itself some ammunition Gothic style, but his beer belly. We try to make the product looked aesthetically pleasing, beautiful.

Year to work

Constantine: Armor, which now stands in our workshop - obraztsa1530 year. This German armor postmaksimilianovskoy era or early Renaissance. He ordered a Minsk businessman, history buff. Over this year we worked armor!

Plate armor Maximilian period. Shoes as a "bear paws". Used for equestrian combat. Virtually invincible, if one is well prepared. Opponents tried to hit the knight in the underarm, cut back the tendon or stab into the slot helmet

The helmet weighs about 5 kg

The smallest attention to detail - an indispensable attribute of any high-quality armor. In fact, it is a work of art

***

***

One of the signs, amulets, which were applied to armor

Victor:

If we talk about simple armor, the shortest period of time for which you can handle - 4-5 months. If we work together.

***

Constantine:

In medieval armor evolved regularly, every 20-30 years. End of XIV - early XV centuries - early Gothic, quite simple in form armor, many elements of the chain mail. But the armor completely covers the body of the soldier. At the end of the XV century appeared graceful lines, edges, reminiscent of water ripples. In the future, technology perfected, the metal becomes thinner and armor - lighter.

Milan armor, XV century

Harvesting of early medieval helmet

Bib and naspinnik gothic breastplate end of the XV century

About props

- If you could send a customer, a businessman in your armor on a medieval battlefield, how quickly would he parted with life?

Victor: It all depends on his combat training! And on armor will be tempered or not. In other words, whether the customer is willing to pay for real combat, working armor. If so, then he will be no worse than they did a few centuries ago. Modern steel is largely allows the armor harder.

- Speaking of weight, an untrained person can feel comfortable, dressed in steel?

Victor

: From what we were doing was the heaviest armor weighing 35-40 kilograms. If done correctly, this can absolutely wear any man, not necessarily an athlete. Weight is distributed throughout the body, he will not hang around his neck like a weight. Another thing, what actions a "knight" will be able to perform.

Italian armor of the middle of the XVI century

- Modern masters to work much better than a medieval?

Constantine

: Of course, in the XVI century, it was different. But in many ways it is now more difficult to us. Then the work was knotted and skills handed down from generation to generation. And masters made armor in the fashion of his time, and we do the armor of various periods. In later centuries, the skill has been largely lost since the need for armor disappeared. As a result, we now have to come up with some things over again, wondering: how it was with them? As for tools, in this respect, of course, we have easier. We do not need horns and medieval methods of cutting, there are grinders, machine tools, electric welding.

- By the way, what kind of activities carried your profession Belarusian officials?

Constantin: Of course, this kind of activity in the register of the Republic of Belarus was not there. Therefore, the registration issued as "activity in the field of art».

Shishak sample of XVII century during assembly

Template for making visor early XV century

Template for iron shoes

***

Armor for rats sometimes allow themselves masters and joke

Salaries and creativity

Victor

: When calculating the cost of a product, we try to succeed by earning at least $ 600 per person per month. That's the minimum. We aim to come to a salary of $ 1,000. Most goes somewhere.

Constantine

: Lay not get more interesting figures: in this case the armor would be difficult to sell. In Belarus, very few people willing to pay the same $ 20 thousand. For the product, which is not less than a year.

Victor:

We do not work solely on salary, to make faster and faster to collect money. We try to make the final product came out in something perfect. If you see some nuances, it is better to change, ask the customer to wait. The question of prestige, image, if you want. As for salaries, then, the feelings, a blacksmith who makes stairs earns more than we do.

Constantine:

The forging business repelled from $ 1,000, we leave this figure does not always. But even this is not important. We do not do routine work, from which the tired psychologically. Just the opposite.

It's pure creativity, which is fun for us and our customers.

that's all, thank you for your attention

Source: