1027

Tank umbrella (11 photos)

There were times when the designers felt that the best protection of the tank against HEAT projectile is ... an umbrella! Yes, yes, do not be surprised, it is in the form of an umbrella that is worn on the barrel of the gun, was made the original protection. So much so, that it even planned to adopt, and only tested on a variety of Soviet tanks.

successful application during the Second World War anti-tank weapons to the cumulative principle defeat armored objects pushed designers and scientists to further improve this type of ammunition. In the postwar years, the cumulative armor shells was increased almost twice.

By this time, it became clear that the book of Soviet tanks T-54, T-55, T-62 does not provide protection against the above ammunition. The thickness of the armor parts of our tanks were: upper front 100 mm at an angle of inclination of 60 °, the lower front sheet 100 mm when tilted 55 °, side having 80 mm at 0 ° and forehead tower 170-90 mm at 23-55 °. Therefore, to prevent cumulative 85mm projectile with copper funnel was necessary to have the thickness of the upper front plate of 215 mm 250 mm of the lower frontal, side hull at least 250 mm at the same angles of inclination. When firing 115-mm HEAT projectiles these parameters were 260, 290 and 200 mm, respectively. Such an increase in the thickness of the armor enclosures tanks would increase their weight by 9-10 tonnes, which, for obvious reasons, was unacceptable.

Therefore, to solve the problem of protection of tanks firing in the direction of the hull sides and in the range of course angles of 25 ° from the cumulative ammunition caliber up to 115 mm in 1964, has been developed and have been thoroughly tested Screens protection ZET-1. It consisted of a continuous mesh windscreen and side skirts.

Properties screens as protection against chemical weapons is based on the fact that when hit at this very screen HEAT projectile his break came to the meeting with the armor of the tank, resulting in a cumulative jet formed before reaching the tank's armor, flew in the air a considerable distance. When moving in the air is jet decay, so that its penetration is sharply reduced, and she could not penetrate the armor.

Weight mesh screen was 60 kg, the minimum distance between the screen and armor - 1800 mm. Time transfer from traveling to combat was 2-3 minutes, and for the installation of the tank on the screen - no more than 15 minutes. The difference screens for T-54/55 and T-62 was only in diameter at the base, fastening on the gun barrel. Side skirts were sectioned type and made of aluminum. Their weight was around 200 kg, the minimum distance between the edge of the tank and the screen section (steering angle to the axis of the tank section in 30 °) was 1500 mm. Time transfer from traveling to combat was about 1 minute, and the installation on podgotovlennny tank - 3 minutes.

The main emphasis in testing complex protection has been on the definition of its vitality during the shelling, as well as durability and reliability in the operation of fixing the tank.

For design ZET-1, it was to ensure the destruction of only one section of the screen when you hit 85-mm shells and two sections in contact 100-115-mm projectile. Conducted in early 1964 test firing almost completely confirmed plans of designers. Further noted that the replacement of one section in the field was only 2 minutes.

No less important step test was to check the reliability of mounting screens. For this experimental tanks T-55 and T-62 underwent sea trials (in a volume of 500 km) to overcome various obstacles. By the end of their stated that mount board as well as the mesh screens are generally quite reliable.

In conclusion, the state commission noted "a significant increase in the effectiveness of the protection of the tank when applying the above protection" and recommended "to take on the supply of the Soviet Army front mesh screen ZET-1." With regard to side skirts encouraged to review their attachment to the tank.

However, the mesh screen is not particularly "settled down" - on the orders of Chief of the Tank-Automotive control their use provided only "threat period, just before the outbreak of hostilities." After adopting the T-64 and T-72 with a fundamentally different structure armor (multilayer) snaryadostoykosti increased need for mesh screens altogether disappeared.

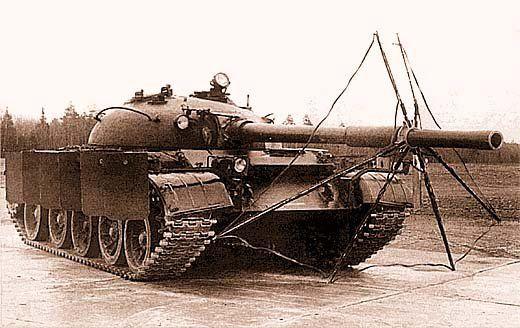

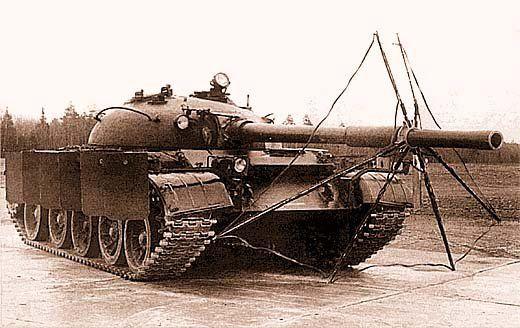

T-55 tank, equipped with an integrated Spaced armor protection (stowed position)

T-55 tank, equipped with an integrated Spaced armor protection (firing position)

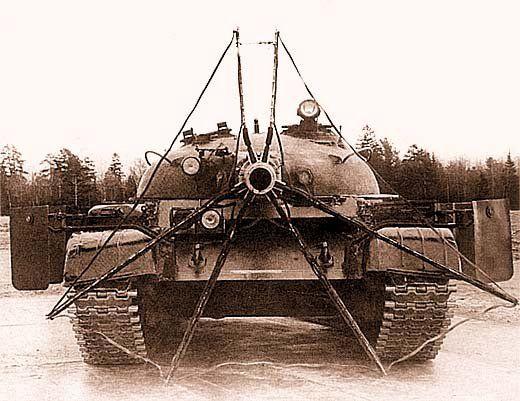

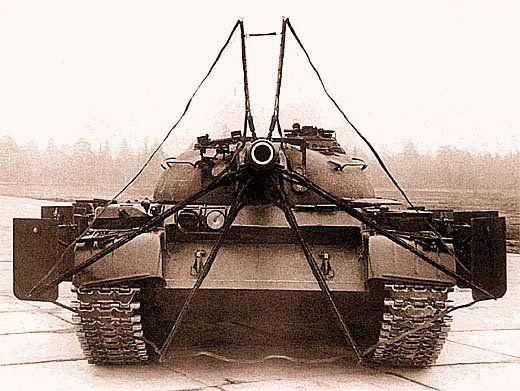

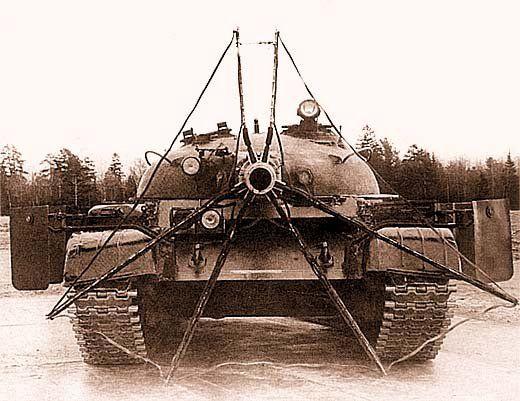

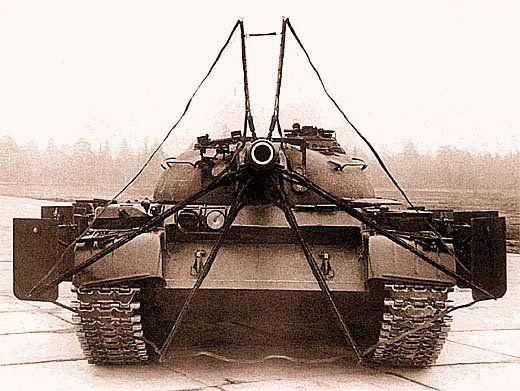

T-62 tank, with integrated Spaced armor protection (stowed position)

T-62 tank, with integrated Spaced armor protection (firing position)

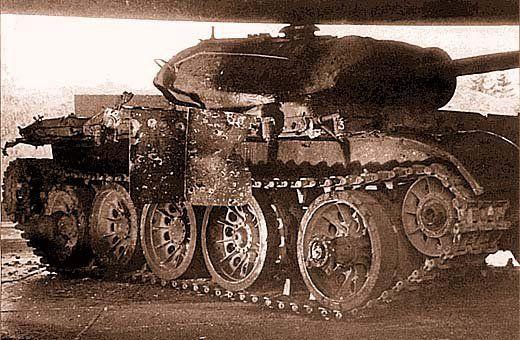

Housing tank T-54, equipped with an integrated screen protection and prepared for the test shell fire

T-62 tank, equipped with an integrated Spaced armor protection, overcomes plot bush

T-55 tank, equipped with an integrated Spaced armor protection (firing position)

Screen status ZET-1 and the upper front plate after hitting the screen 100mm shaped-charge fragmentation snayaryada gun T-12

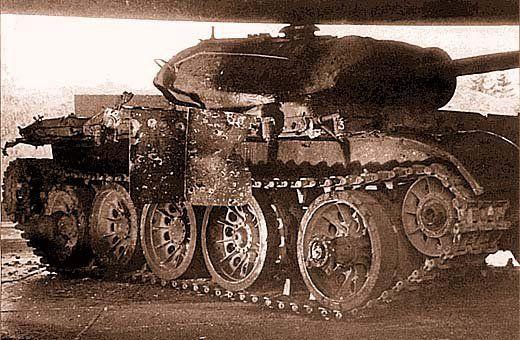

View shield starboard hull of the T-54 after four hits 85-mm HEAT projectile with copper funnel

View shield starboard hull of the T-54 after the first hit 85-mm HEAT projectile

successful application during the Second World War anti-tank weapons to the cumulative principle defeat armored objects pushed designers and scientists to further improve this type of ammunition. In the postwar years, the cumulative armor shells was increased almost twice.

By this time, it became clear that the book of Soviet tanks T-54, T-55, T-62 does not provide protection against the above ammunition. The thickness of the armor parts of our tanks were: upper front 100 mm at an angle of inclination of 60 °, the lower front sheet 100 mm when tilted 55 °, side having 80 mm at 0 ° and forehead tower 170-90 mm at 23-55 °. Therefore, to prevent cumulative 85mm projectile with copper funnel was necessary to have the thickness of the upper front plate of 215 mm 250 mm of the lower frontal, side hull at least 250 mm at the same angles of inclination. When firing 115-mm HEAT projectiles these parameters were 260, 290 and 200 mm, respectively. Such an increase in the thickness of the armor enclosures tanks would increase their weight by 9-10 tonnes, which, for obvious reasons, was unacceptable.

Therefore, to solve the problem of protection of tanks firing in the direction of the hull sides and in the range of course angles of 25 ° from the cumulative ammunition caliber up to 115 mm in 1964, has been developed and have been thoroughly tested Screens protection ZET-1. It consisted of a continuous mesh windscreen and side skirts.

Properties screens as protection against chemical weapons is based on the fact that when hit at this very screen HEAT projectile his break came to the meeting with the armor of the tank, resulting in a cumulative jet formed before reaching the tank's armor, flew in the air a considerable distance. When moving in the air is jet decay, so that its penetration is sharply reduced, and she could not penetrate the armor.

Weight mesh screen was 60 kg, the minimum distance between the screen and armor - 1800 mm. Time transfer from traveling to combat was 2-3 minutes, and for the installation of the tank on the screen - no more than 15 minutes. The difference screens for T-54/55 and T-62 was only in diameter at the base, fastening on the gun barrel. Side skirts were sectioned type and made of aluminum. Their weight was around 200 kg, the minimum distance between the edge of the tank and the screen section (steering angle to the axis of the tank section in 30 °) was 1500 mm. Time transfer from traveling to combat was about 1 minute, and the installation on podgotovlennny tank - 3 minutes.

The main emphasis in testing complex protection has been on the definition of its vitality during the shelling, as well as durability and reliability in the operation of fixing the tank.

For design ZET-1, it was to ensure the destruction of only one section of the screen when you hit 85-mm shells and two sections in contact 100-115-mm projectile. Conducted in early 1964 test firing almost completely confirmed plans of designers. Further noted that the replacement of one section in the field was only 2 minutes.

No less important step test was to check the reliability of mounting screens. For this experimental tanks T-55 and T-62 underwent sea trials (in a volume of 500 km) to overcome various obstacles. By the end of their stated that mount board as well as the mesh screens are generally quite reliable.

In conclusion, the state commission noted "a significant increase in the effectiveness of the protection of the tank when applying the above protection" and recommended "to take on the supply of the Soviet Army front mesh screen ZET-1." With regard to side skirts encouraged to review their attachment to the tank.

However, the mesh screen is not particularly "settled down" - on the orders of Chief of the Tank-Automotive control their use provided only "threat period, just before the outbreak of hostilities." After adopting the T-64 and T-72 with a fundamentally different structure armor (multilayer) snaryadostoykosti increased need for mesh screens altogether disappeared.

T-55 tank, equipped with an integrated Spaced armor protection (stowed position)

T-55 tank, equipped with an integrated Spaced armor protection (firing position)

T-62 tank, with integrated Spaced armor protection (stowed position)

T-62 tank, with integrated Spaced armor protection (firing position)

Housing tank T-54, equipped with an integrated screen protection and prepared for the test shell fire

T-62 tank, equipped with an integrated Spaced armor protection, overcomes plot bush

T-55 tank, equipped with an integrated Spaced armor protection (firing position)

Screen status ZET-1 and the upper front plate after hitting the screen 100mm shaped-charge fragmentation snayaryada gun T-12

View shield starboard hull of the T-54 after four hits 85-mm HEAT projectile with copper funnel

View shield starboard hull of the T-54 after the first hit 85-mm HEAT projectile