1134

Construction of a thermal power plant

Cogeneration (CHP) - is a thermal power plant, which produces not only electricity, but also a source of heat energy in centralized heat supply systems (heating, hot water).

Outside it looks like the most common building.

New pipes.

Beautiful pipe connection. Pipe diameter of 50 cm.

Welding works.

The process of obtaining energy for multi-purposes, in order to increase the overall efficiency of the power plant. In the first stage gas turbines rotated generators that produce electricity.

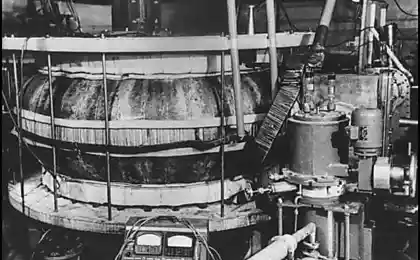

Then, the exhaust gases from the gas turbine plant fall into the pot (see photo). The water in the boiler is heated in the boiler drum and steam is obtained.

Further steam enters the steam turbine on the same axis which is also a generator producing electricity.

The steam turbine.

At this stage there is a selection of steam to heat the water.

Walking through the CHP

General view of the machine room. In total there are about 8 floors.

View from above.

At the bottom of gas turbines.

Gas turbine. From above, through the intake air enters from the street. Away - gas turbine, in the foreground - a generator. Further, the depth of the boiler is located.

On the cover of the boiler. View a nearby boiler.

The drum boiler in which steam mixture is separated into vapor and water. Water is again in a standpipe, and saturated steam goes into the superheater. Most of the low quality water to the boiler tubes occurs precipitation of the salts of calcium, magnesium, and other substances. To pipe is not clogged deposits should be regularly as a service to the boiler and boiler tubes.

Outside the drum is covered with insulation (for this purpose on the body of the drum is welded thick wire).

Neighboring boiler.

Outside it looks like the most common building.

New pipes.

Beautiful pipe connection. Pipe diameter of 50 cm.

Welding works.

The process of obtaining energy for multi-purposes, in order to increase the overall efficiency of the power plant. In the first stage gas turbines rotated generators that produce electricity.

Then, the exhaust gases from the gas turbine plant fall into the pot (see photo). The water in the boiler is heated in the boiler drum and steam is obtained.

Further steam enters the steam turbine on the same axis which is also a generator producing electricity.

The steam turbine.

At this stage there is a selection of steam to heat the water.

Walking through the CHP

General view of the machine room. In total there are about 8 floors.

View from above.

At the bottom of gas turbines.

Gas turbine. From above, through the intake air enters from the street. Away - gas turbine, in the foreground - a generator. Further, the depth of the boiler is located.

On the cover of the boiler. View a nearby boiler.

The drum boiler in which steam mixture is separated into vapor and water. Water is again in a standpipe, and saturated steam goes into the superheater. Most of the low quality water to the boiler tubes occurs precipitation of the salts of calcium, magnesium, and other substances. To pipe is not clogged deposits should be regularly as a service to the boiler and boiler tubes.

Outside the drum is covered with insulation (for this purpose on the body of the drum is welded thick wire).

Neighboring boiler.

The most expensive home theater in the world (22 photos)

The terrible disaster in the Gulf of Mexico