2217

How to make the pipe on TOO Pavlodar Pipe Rolling Plant

TOO Pavlodar Tube Rolling Plant is located in the Republic of Kazakhstan in Pavlodar. Kazakhstan is the first plant for the production of steel pipes of a wide assortment (15-219 mm).

Tubular products produced at the plant is used in the creation of systems of water and gas, heating, sanitation, various utilities, boiler systems, irrigation systems, and more. Blanks for production of pipes supplies Pavlodar steel mill.

Production process tube consists of the following steps: hot rolling line in which is cut, heated, rolled and sewn molded preform to obtain the desired length of the pipe wall thickness.

Then, if necessary, heat treated tube or goes directly to the scan line quality and finishing line. After completing all the necessary operations of the pipe ready for shipment.

Rotary heating furnace, which is designed to heat up to a temperature of the material placed in the furnace in the most uniform manner.

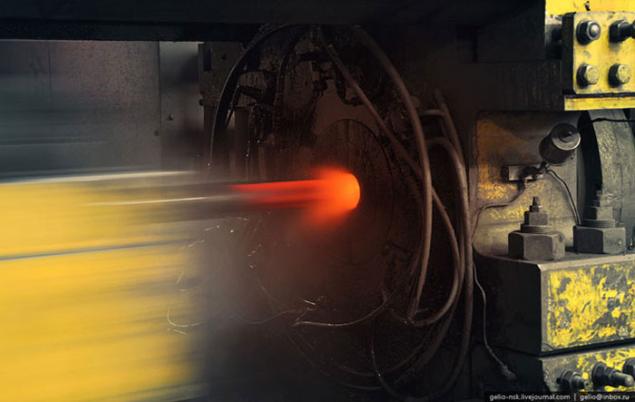

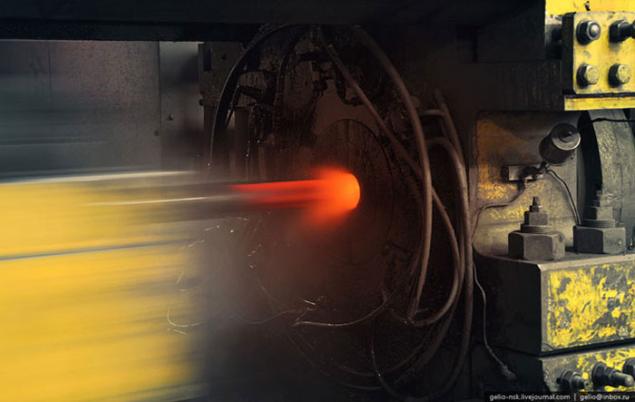

Kosovalkovy piercing mill, which converts into a hollow workpiece blank with large wall thickness.

Continuous hot rolling pipes on a mandrel retained (RMM) with six stands - true heart of the plant, followed izvlekatelny mill with three stands - their function is to convert the hollow workpiece (3 meter) obtained in kosovalkovom piercing mill, the pipe, which has a relatively thin wall over the hollow shell and has a length up to 28 m.

Next comes the reheating furnace, reducing mill and the cooling table.

The design capacity is 100,000 tons per year.

Workpiece at Tube plant supplies neighbor towering over the factory road - Pavlodar steel plant (LLP "Casting").

TOO "Casting" since 1994 and is a diversified enterprise, operating in the sphere of secondary ferrous and nonferrous metals.

The plant annually produces 1, 2 million tons, and 95 percent of the raw material is scrap (the rest - various additives to produce a particular grade of steel or cast iron).

Of these, 270 thousand tons of repeat constitute iron ingots for rolling plant.

The cars drive up on the rails of different-sized scrap directly to the furnaces where temperature of 1500 degrees and there is a "reincarnation" of raw materials.

Tubular products produced at the plant is used in the creation of systems of water and gas, heating, sanitation, various utilities, boiler systems, irrigation systems, and more. Blanks for production of pipes supplies Pavlodar steel mill.

Production process tube consists of the following steps: hot rolling line in which is cut, heated, rolled and sewn molded preform to obtain the desired length of the pipe wall thickness.

Then, if necessary, heat treated tube or goes directly to the scan line quality and finishing line. After completing all the necessary operations of the pipe ready for shipment.

Rotary heating furnace, which is designed to heat up to a temperature of the material placed in the furnace in the most uniform manner.

Kosovalkovy piercing mill, which converts into a hollow workpiece blank with large wall thickness.

Continuous hot rolling pipes on a mandrel retained (RMM) with six stands - true heart of the plant, followed izvlekatelny mill with three stands - their function is to convert the hollow workpiece (3 meter) obtained in kosovalkovom piercing mill, the pipe, which has a relatively thin wall over the hollow shell and has a length up to 28 m.

Next comes the reheating furnace, reducing mill and the cooling table.

The design capacity is 100,000 tons per year.

Workpiece at Tube plant supplies neighbor towering over the factory road - Pavlodar steel plant (LLP "Casting").

TOO "Casting" since 1994 and is a diversified enterprise, operating in the sphere of secondary ferrous and nonferrous metals.

The plant annually produces 1, 2 million tons, and 95 percent of the raw material is scrap (the rest - various additives to produce a particular grade of steel or cast iron).

Of these, 270 thousand tons of repeat constitute iron ingots for rolling plant.

The cars drive up on the rails of different-sized scrap directly to the furnaces where temperature of 1500 degrees and there is a "reincarnation" of raw materials.