1999

As in Kazakhstan collected 250 SUV a month

As in Kazakhstan harvested 250 SUV a month and why the plant plays classical music, then read in a report

36 photos

"Our must be great!", "To understand the situation - you need to go and see yourself!" ... Posters. This is the first thing that catches the eye in the shops of the plant LLP "SaryarkaAvtoProm."

As it turned out, this experience is taken over from the Japanese. Kostanaytsy it taken note of the Japanese factory Toyota. And hardly been mounted shop, it placed posters. This, according to the plant's management, motivates the creation of a quality product.

LLP "SaryarkaAvtoProm" - the first company in Kazakhstan, which switched to CKD production, including welding, painting and assembly. It is based on Kostanay automotive plant, whose purpose - the car is 100% made in Kazakhstan

Motivation system is visible in the evaluation of work of people making first SUV Kazakh production. The average of their salary - 90 thousand tenge, excluding premiums. When calculating premiums accounted for all: APPROVED marriage work, delay or, conversely, an initiative overfulfilment quality.

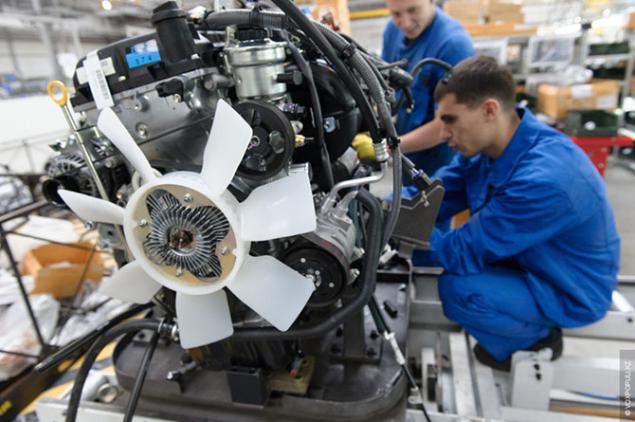

It all starts in the welding shop. There basically are young boys of 20-25 years. Recent graduates of local colleges and universities. Firstly, because they are easier to retrain, secondly - and here you need to run and jump, and use physical force.

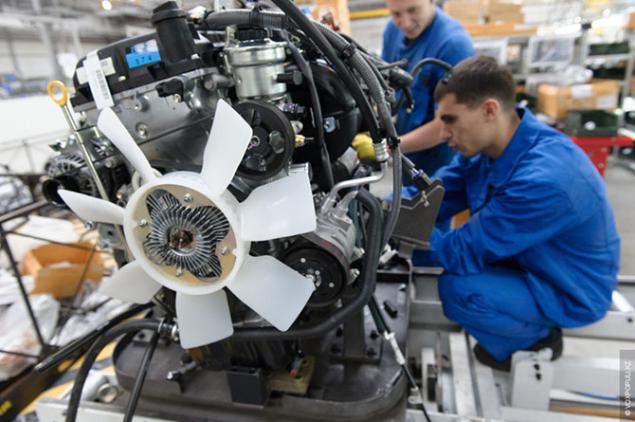

- All items come from Japan, stamped, we weld them - says brand manager Alexander Revenko. - Stamping equipment - it is very expensive, after paying off a million bodies. Maybe sometime it will Kostanay. In the meantime, we plan for the year - 3000 cars.

A welding machine weighs 50 kg.

All this equipment was first collected in Japan. Tested and then disassembled and shipped to Kostanay. Japanese experts during assembly came several times in Kazakhstan. Ticker measured all racks. In their scheme was registered, where, and at what angle they should stand up to the millimeter! Purpose - the employee does not even have to do extra steps, pan, tilt.

Another memorable Japanese kostanaytsy high secrecy. No scheme, only pictures of future workshops. That is the policy of the company. All that it is designed only her. Employees numbered notebooks and flash drives. And your laptop is only suitable utility fleshkarte. The whole story is written up and then verified by the Japanese security service.

Time wasted - there is a huge luxury. These savings, of course, increases efficiency. But this is not important, explained to the Japanese, in such calculations arrangement of the workplace and people less tired. Such concern for the workers. But we should not deceive ourselves greatly. Pipelined mode dictates its own rules. Here's a schedule. During the day, two smoke break of 10 minutes and one hour for lunch. Some employees joke: the rhythm of conveyor adjusts so that the toilet and on schedule walk.

Welder Vadim Simonov only twenty, and he has already foreman:

- I was in college the road. After went home on the wheat harvest. Season worked and returned to the city. Here and learned that the set goes. Taught us Japanese. I regret only that the Japanese do not know. They have some very different approach to work. They all desire to do, not because it should be. I consider myself very lucky that we Kostanay open such proceedings. In the 20 years I have had this experience, which I never dreamed.

The body comes in Kostanay understand. The task Welder - assemble it in 34 minutes. The day is roughly 11-12 bodies. The first test body Kostanajsky Toyota, remember guys, still under the guidance of the Japanese one shift they did not have time to cook. Now even ridiculous, and yet it took only 8 months.

- It is this model of Toyota in Central Asia collected only Kostanay - said Alexander Illarionov, a visiting specialist, change to Kostanay work at AvtoVAZ. - I think what is happening now in Kostanay - is an event for the whole Kazakhstan. I have something to compare. For the year here committed a strong leap forward. A year ago, cleaned the demolition of old equipment, machine tools, and in the plain began to build the shop. Less than a year - and here, see for yourself.

After welding, semi-finished Toyota fall into the clutches of the measuring laboratory. Here specialists check the geometry of the body.

But the fact that every body takes 13 baths, this is not all motorists know. In each bath the different chemical solutions. They cleanse the body from all sorts of substances, which can make the color is simply useless. Gives a "skinny" and anticorrosive effect.

In addition to chemical circular shower cars also takes cataphoresis bath. That is a clean machine discharge current. This gives future staining effect uniformity. Near the bath is acid odor, the ionized air.

After bathing - drying. Oven with the heat to 180 degrees. As for painting, there colorists Toyota future its owners are ready to meet. The range of colors wide.

At this stage, work mostly by men. But Foreman applying mastic - Alain Claus, who arrived a year ago to Kostanay from Ukraine. Allen calls herself eminence grise. It is not always noticeable, but always near, supervises the work of subordinates.

Bottom is covered with mastic and noise.

And then, when the body is ready for transformation, for it is taken specialists primer. The mastic is applied manually on each weld. This is for sealing to the salon did not get neither water nor even smells.

At this stage of the Transfiguration in the ranks of the working girls there.

On assembling them and did most.

Skillfully wielded screwdrivers, giving 8 cars per hour.

They say they work neater men. This, incidentally, during his visit to the factory and said Nursultan Nazarbayev. And here, as if deliberately, for the beautiful half of the plant a Japanese technique of the matter includes various classical melodies.

As it turned out, because the system reports on a new phase of work. To quickly get used to the normal beeping, and here - a classic.

That's happening aesthetically birth Kazakh Toyota.

After assembly, start multiple test steps.

Control both the appearance and functionality of a car.

Then the test track. Vibration, noise, braking, turning, behavior on rough roads - are all evaluated. And then again in the shop: overseers locksmiths look like cars responded to the first run.

The process of assembling Toyota Fortuner, in fact, if you calculate it on the same machine, only takes half an hour.

Cost Kostanajsky Toyota service centers - from 37 thousand dollars.

In the workshops to assemble Toyota almost every day journalists. Automotive industry is particularly interested in Kostanay republican press. Working laugh: "Do not shop, and a film set some kind."

They are to this already so accustomed to, that is simply not paying attention.

President Nursultan Nazarbayev visited Kostanaiskiy Autoworks, left his autograph on one of the cars. Since the present car lined up wanting to buy it, but it was decided to leave the copy in the museum business. While the latter is constructed, the presidential Toyota has already visited the exhibition in Astana. The other day the President returned to autograph Kostanai.

- Everyone understands that what is happening here, of course, the event - said Bakchan Khousainov, head of the design bureau, a professional with 40 years of experience. - Here I am, when KOSTANAY food and meet on the road with our Toyota, it is so pleasant to the soul becomes. Not even for himself. For the country. I'll say this, a lot we can. And the Japanese with us knowingly cooperate steel. That's just giving us the experience we have, by the way, something took over the. Interested, asked recording ...

That's right, a classic tune and flash cameras, comes a new product Kazakhstan. With a name that literally translates as "successful." And start, seems to have become so. To date, of the 380 produced in Kostanai SUV Toyota Fortuner has already sold nearly half. For 8 months.

Last

While they are familiar only Kazakh road. International market - future plans.

Hence

36 photos

"Our must be great!", "To understand the situation - you need to go and see yourself!" ... Posters. This is the first thing that catches the eye in the shops of the plant LLP "SaryarkaAvtoProm."

As it turned out, this experience is taken over from the Japanese. Kostanaytsy it taken note of the Japanese factory Toyota. And hardly been mounted shop, it placed posters. This, according to the plant's management, motivates the creation of a quality product.

LLP "SaryarkaAvtoProm" - the first company in Kazakhstan, which switched to CKD production, including welding, painting and assembly. It is based on Kostanay automotive plant, whose purpose - the car is 100% made in Kazakhstan

Motivation system is visible in the evaluation of work of people making first SUV Kazakh production. The average of their salary - 90 thousand tenge, excluding premiums. When calculating premiums accounted for all: APPROVED marriage work, delay or, conversely, an initiative overfulfilment quality.

It all starts in the welding shop. There basically are young boys of 20-25 years. Recent graduates of local colleges and universities. Firstly, because they are easier to retrain, secondly - and here you need to run and jump, and use physical force.

- All items come from Japan, stamped, we weld them - says brand manager Alexander Revenko. - Stamping equipment - it is very expensive, after paying off a million bodies. Maybe sometime it will Kostanay. In the meantime, we plan for the year - 3000 cars.

A welding machine weighs 50 kg.

All this equipment was first collected in Japan. Tested and then disassembled and shipped to Kostanay. Japanese experts during assembly came several times in Kazakhstan. Ticker measured all racks. In their scheme was registered, where, and at what angle they should stand up to the millimeter! Purpose - the employee does not even have to do extra steps, pan, tilt.

Another memorable Japanese kostanaytsy high secrecy. No scheme, only pictures of future workshops. That is the policy of the company. All that it is designed only her. Employees numbered notebooks and flash drives. And your laptop is only suitable utility fleshkarte. The whole story is written up and then verified by the Japanese security service.

Time wasted - there is a huge luxury. These savings, of course, increases efficiency. But this is not important, explained to the Japanese, in such calculations arrangement of the workplace and people less tired. Such concern for the workers. But we should not deceive ourselves greatly. Pipelined mode dictates its own rules. Here's a schedule. During the day, two smoke break of 10 minutes and one hour for lunch. Some employees joke: the rhythm of conveyor adjusts so that the toilet and on schedule walk.

Welder Vadim Simonov only twenty, and he has already foreman:

- I was in college the road. After went home on the wheat harvest. Season worked and returned to the city. Here and learned that the set goes. Taught us Japanese. I regret only that the Japanese do not know. They have some very different approach to work. They all desire to do, not because it should be. I consider myself very lucky that we Kostanay open such proceedings. In the 20 years I have had this experience, which I never dreamed.

The body comes in Kostanay understand. The task Welder - assemble it in 34 minutes. The day is roughly 11-12 bodies. The first test body Kostanajsky Toyota, remember guys, still under the guidance of the Japanese one shift they did not have time to cook. Now even ridiculous, and yet it took only 8 months.

- It is this model of Toyota in Central Asia collected only Kostanay - said Alexander Illarionov, a visiting specialist, change to Kostanay work at AvtoVAZ. - I think what is happening now in Kostanay - is an event for the whole Kazakhstan. I have something to compare. For the year here committed a strong leap forward. A year ago, cleaned the demolition of old equipment, machine tools, and in the plain began to build the shop. Less than a year - and here, see for yourself.

After welding, semi-finished Toyota fall into the clutches of the measuring laboratory. Here specialists check the geometry of the body.

But the fact that every body takes 13 baths, this is not all motorists know. In each bath the different chemical solutions. They cleanse the body from all sorts of substances, which can make the color is simply useless. Gives a "skinny" and anticorrosive effect.

In addition to chemical circular shower cars also takes cataphoresis bath. That is a clean machine discharge current. This gives future staining effect uniformity. Near the bath is acid odor, the ionized air.

After bathing - drying. Oven with the heat to 180 degrees. As for painting, there colorists Toyota future its owners are ready to meet. The range of colors wide.

At this stage, work mostly by men. But Foreman applying mastic - Alain Claus, who arrived a year ago to Kostanay from Ukraine. Allen calls herself eminence grise. It is not always noticeable, but always near, supervises the work of subordinates.

Bottom is covered with mastic and noise.

And then, when the body is ready for transformation, for it is taken specialists primer. The mastic is applied manually on each weld. This is for sealing to the salon did not get neither water nor even smells.

At this stage of the Transfiguration in the ranks of the working girls there.

On assembling them and did most.

Skillfully wielded screwdrivers, giving 8 cars per hour.

They say they work neater men. This, incidentally, during his visit to the factory and said Nursultan Nazarbayev. And here, as if deliberately, for the beautiful half of the plant a Japanese technique of the matter includes various classical melodies.

As it turned out, because the system reports on a new phase of work. To quickly get used to the normal beeping, and here - a classic.

That's happening aesthetically birth Kazakh Toyota.

After assembly, start multiple test steps.

Control both the appearance and functionality of a car.

Then the test track. Vibration, noise, braking, turning, behavior on rough roads - are all evaluated. And then again in the shop: overseers locksmiths look like cars responded to the first run.

The process of assembling Toyota Fortuner, in fact, if you calculate it on the same machine, only takes half an hour.

Cost Kostanajsky Toyota service centers - from 37 thousand dollars.

In the workshops to assemble Toyota almost every day journalists. Automotive industry is particularly interested in Kostanay republican press. Working laugh: "Do not shop, and a film set some kind."

They are to this already so accustomed to, that is simply not paying attention.

President Nursultan Nazarbayev visited Kostanaiskiy Autoworks, left his autograph on one of the cars. Since the present car lined up wanting to buy it, but it was decided to leave the copy in the museum business. While the latter is constructed, the presidential Toyota has already visited the exhibition in Astana. The other day the President returned to autograph Kostanai.

- Everyone understands that what is happening here, of course, the event - said Bakchan Khousainov, head of the design bureau, a professional with 40 years of experience. - Here I am, when KOSTANAY food and meet on the road with our Toyota, it is so pleasant to the soul becomes. Not even for himself. For the country. I'll say this, a lot we can. And the Japanese with us knowingly cooperate steel. That's just giving us the experience we have, by the way, something took over the. Interested, asked recording ...

That's right, a classic tune and flash cameras, comes a new product Kazakhstan. With a name that literally translates as "successful." And start, seems to have become so. To date, of the 380 produced in Kostanai SUV Toyota Fortuner has already sold nearly half. For 8 months.

Last

While they are familiar only Kazakh road. International market - future plans.

Hence