349

Formation of roads on the basis of concrete slabs: features, stages

Plate laying is the fastest and easiest way to build a roadway. Concrete products can be used repeatedly. The roads created on their basis are characterized by high strength, durability, resistance to loads and numerous negative factors. The paintings do not require shrinkage, the involvement of numerous working groups. They can be used immediately, including for heavy traffic or heavy machinery.

Laying of road plates: what you need to know

The characteristics of the roadway will depend on two main factors - the material used and compliance with the technology of its installation. In choosing plates, it is necessary to take into account the upcoming loads, the duration of operation, the peculiarities of the climate, etc. If on the territory of a private house you can use options of the least strength, used plate, then for an access construction, warehouse or industrial road it is better to buy new ones that can withstand at least 2.2-2.5 tons per square meter.

Paths for wheeled equipment should be lined with grooved surface, for tracked - with smooth. Before installing plates, it is necessary to properly prepare the platform. You'll have to bring in good crane equipment. The heavy weight of concrete products does not allow to perform work manually. It is profitable to buy road plates from the manufacturer. The supply of such materials is carried out by Stroynerud.

Stages of installation of road plates

The process of laying plate roads and sites can be divided into several stages:

If installation work is performed on an undeveloped site, the first thing you need to cut the top layer of soil with vegetation. The entire area should be leveled under one level. Next, it is necessary to make a trench to a depth of 30-50 cm. The latter is determined taking into account the bearing abilities of the soil, the intensity of the application of the track.

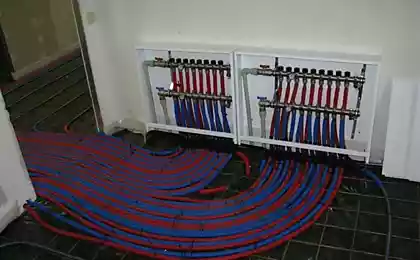

To prevent the growth of weeds, the risk of erosion, you need to floor geotextile. It is suitable as intermediate layers, eliminating the likelihood of mixing the structure. The pillow must be formed from rubble and sand. The first layer should be 10 cm, the second - 20 cm. After pouring water, the base should be carefully tamped. This will prevent plate displacement.

Laying plate blocks can be done with gaps and without. If there are gaps, they must be filled with sand. To strengthen the coatings designed for heavy equipment, the sand layer must be replaced with cement mortar. For greater stability of the design, you can weld mounting loops of neighboring plates

Prepared by materials gbistroj.ru/

Laying of road plates: what you need to know

The characteristics of the roadway will depend on two main factors - the material used and compliance with the technology of its installation. In choosing plates, it is necessary to take into account the upcoming loads, the duration of operation, the peculiarities of the climate, etc. If on the territory of a private house you can use options of the least strength, used plate, then for an access construction, warehouse or industrial road it is better to buy new ones that can withstand at least 2.2-2.5 tons per square meter.

Paths for wheeled equipment should be lined with grooved surface, for tracked - with smooth. Before installing plates, it is necessary to properly prepare the platform. You'll have to bring in good crane equipment. The heavy weight of concrete products does not allow to perform work manually. It is profitable to buy road plates from the manufacturer. The supply of such materials is carried out by Stroynerud.

Stages of installation of road plates

The process of laying plate roads and sites can be divided into several stages:

- preparatory;

- primary;

- final.

If installation work is performed on an undeveloped site, the first thing you need to cut the top layer of soil with vegetation. The entire area should be leveled under one level. Next, it is necessary to make a trench to a depth of 30-50 cm. The latter is determined taking into account the bearing abilities of the soil, the intensity of the application of the track.

To prevent the growth of weeds, the risk of erosion, you need to floor geotextile. It is suitable as intermediate layers, eliminating the likelihood of mixing the structure. The pillow must be formed from rubble and sand. The first layer should be 10 cm, the second - 20 cm. After pouring water, the base should be carefully tamped. This will prevent plate displacement.

Laying plate blocks can be done with gaps and without. If there are gaps, they must be filled with sand. To strengthen the coatings designed for heavy equipment, the sand layer must be replaced with cement mortar. For greater stability of the design, you can weld mounting loops of neighboring plates

Prepared by materials gbistroj.ru/

A penny replacement for purchased rain trays, a home builder for joy

How to choose the right forklift for rent: the main criteria