623

Where are metering pumps used, their specifics

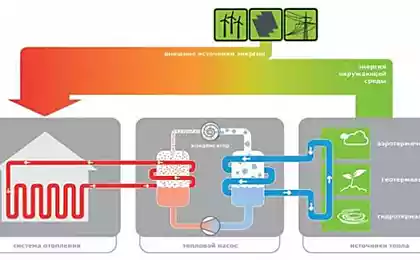

Often, liquids entering the working environment under strong pressure require strict dosing. That is why special devices are created to guarantee accurate measurements. Such units are adapted to work with suspensions, aggressive or chemically neutral media, with emulsions and even with toxic compositions. High-quality dosing pumps are also needed for water purification, in other areas where measurement accuracy is required.

The specificity of the use of units

It is important to ensure maximum accuracy, for example, the health of people largely depends on this. So, in urban conditions, chlorine or other compounds are often added to the water to neutralize pathogenic microflora, the excess of which will negatively affect the condition of people. This is just one of hundreds of similar examples. Features:

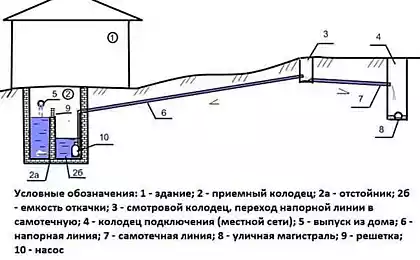

- There are sewer pumps, monoblock, vertical, circulating.

- Demand in industry and units with a dry rotor, vertical, as well as specially designed for urban water supply systems.

- The nominal flow rate and head, parameters of the impellers, the specifics of the shaft, materials of the base, and the impeller are described.

What quality equipment should be

The description must contain information about the manufacturer, warranty. Average warranty is 1-2 years, sometimes longer. Buyers should also be aware of the maximum permissible ambient temperature at which the manufacturer guarantees the normal functioning of the devices. Other nuances:

- Maximum allowable pressure is stated.

- The specifics of the working fluid must also be indicated, because it can be not only water.

- What matters is the frequency of the supply network, rated power, voltage, type of electric motor, degree of protection, class of insulation.

If the product is genuinely original, then the guarantee will be confirmed in writing. Plus, accompanying documents, a product passport, an operation manual must be available. Within the period established by law, it will be possible to return the product, exchange it for another one with the desired parameters.

Recommendations for aspiring English teachers

Slot machines in online casinos Pin-Up amaze not only in number, but also high returns.