780

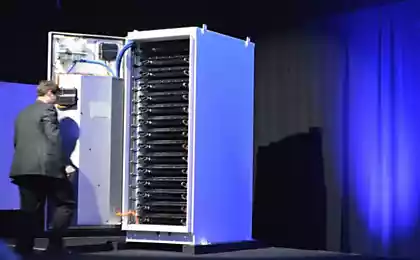

Variable frequency drive guard energy savings

The more wealth appears in the house, the greater burden falls on the shoulders of the power system. As a result, grow the electricity bills, and many owners are trying by all means to reduce this expenditure, by resorting to various energy-saving technologies. Appliances energy class not lower than "A", efficient lighting and much more can be seen in almost every home. However, suburban housing with auxiliary water supply in addition to the above methods you can offer and another quite attractive method of saving.

A considerable part of the electricity consumed in the movement of water and gases in such devices as pumps, fans, compressors. This equipment is used for the heating system, drinking water supply (not only centralized, but individual), functioning of the sewage, industrial moving liquids and gases.

In most cases, the energy here is spent irrationally. Due to the fact that consumption in these systems is uneven. It has peaks with a maximum load, which occupies a very small part of the time and rarely exceeding a couple of hours per day. It is these peaks and the calculated equipment such as a pump or blower. Basically you want 100% flow liquid or gas, and in the area of 30-40% of the maximum possible load. It is easy to see, for example, peaks of demand systems in Central drinking water supply: morning and evening high contrasted night minimum. However, the pump continues to operate at full capacity and to consume 100% energy.

To date, there is already a solution to this problem — variable frequency drive (CRAP), it will be discussed below.

Principles of regulation of the fluid flow without the use of CRAPto evaluate the benefits of frequency control, think about the commonly used traditional methods of reducing the flow of liquid or gas. For simplicity, the examples will be adduced in a normal water pipe with a standard pump, leaving aside the movement of air, oil, gas and various industrial liquids. By the way, the principles will be similar in many ways.

One of the first to examine the regulation by means of a bypass. This is a bypass line, which is an offshoot from the main pipe that returns part is pumped by the pump fluid back to the flow of the same pump. Despite the possibility of fairly precise adjustment of the system to the defined parameters of the water flow, the efficiency of her incredibly low.

Next on the list we can consider the regulation with valves and other devices installed between the pump and limiting the useful section of the pipeline. This option can also be viewed as a throwaway, a considerable part of the electricity is wasted as it creates a large pressure cut off these devices to the required level.

Another option regulation periodic operation of the pumps. It involves the inclusion of equipment only for filling tanks, battery water, after which there is an automatic stop. Of the above he has, perhaps, the best efficiency, however, is not without drawbacks:

The principle of regulation of fluid flow with application CRAPRegulation of fluid flow using variable frequency drives is designed to reduce the percentage of wasted energy in all areas where motors are used, and also has a variable load.

Such equipment includes not only the working mechanism of the pump and the motor. Here the main role plays the so-called "chastotnik", the frequency Converter. Through the established network of sensors, it reacts to changes and controls the feed: its output is formed a predetermined voltage with a particular amplitude, which, in turn, causes the motor and, accordingly, the operating mechanism of the pump to rotate with a certain (slow) speed. So when the flow rate increases to a peak pump will work with full dedication, but immediately when the decrease in demand will react by reducing the speed of rotation of the operating mechanism. And, accordingly, reduced energy consumption.

Therefore, the same volume of fluid delivered to the desired tap pump with CRAP, will require less money than use up a similar scheme with a constant speed of rotation of the working mechanism of the equipment. This allows you to abandon these ineffective management techniques like throttling or using by-passes.

Application CRAP for submersible pumpsAs mentioned above, in a typical country house, it is also possible to apply the technology of frequency control. It is possible to realize it in the hot water supply, heating, or downhole pump. The last option we consider in more detail, since that is where there is the most pronounced and understandable for the average person the frequency of load:

Today it is possible not only to buy ready made pump with adjustable drive, but retrofitting an already installed frequency Converter. The latter when used in conjunction with a downhole submersible pump should have the following set of features:

Built-in PID (sometimes PI, but these occur less often in the sale) regulator. The possibility of power optimization, allowing to reduce the normal voltage with a slight load on the actuator. The ability to re-start the drive after a fault or error of automation without human intervention. Motor protection against overload. Engine protection from overheating. The short circuit protection. Pump protection against running dry, i.e. without water in the fall of the level in the well below the suction pipe. The fluid is for unit cooling and lubrication, so its absence in the running pump can lead to overheating and rapid failure. The "sleep" mode when using the inverter in conjunction with a pump that has a limit to work at very low speeds. Archive of accidents. This option is indispensable for the clarification of the peculiarities of operation of the device in specific circumstances when repeated (periodic) outputs of the system. Scalar (volts-Hz U/f) or vector control for more precise adjustment of the actuator for normal smooth (without jerks).

With regard to equipment selection, we can highlight the following points:

When you select "chastotnik" should pay more attention not to power, and the rated current, and should provide for some margin. This is due to the fact that submersible motors nominal current is slightly higher than that of standard motors. Overload capacity installed "chastotnik" must be large enough (over 120%), otherwise, this deficiency must be compensated by the engine power, which will be somewhat higher. In cases where the transducer will be located in an unheated room, it must have the appropriate operating temperature range and suitable protection class. In addition to the main equipment should pay attention to the cable — it should be a big section in order to prevent voltage loss along the length. As additional protection you can install a motor choke, it further protects from large current leakage and tripping the overload protection. Before the inverter (Converter) you can also set a network throttle, he, in turn, will eliminate trouble from a distribution transformer.

Advantages CRAP in addition to energy savingsin Addition to saving energy equipment pumps adjustable electric drive has other positive side.

First, significantly, by almost half, increasing the life of equipment, as it reduces the number of starts and shutdowns.

Second, it is possible to significantly reduce the capacity of the storage tank, as the flow rate increases the pump automatically starts to work more efficiently. To any maximum consumption has not led to a reduction of pressure in the network, the installation can be provided in the pump with obviously more power — consumption of electricity will rise slightly.

Another positive factor is the smooth starts and stops, which negates the likelihood of water hammer in a network. As a result, not only the equipment, but also the water supply will last longer than usual.

Manufacturers and payback periodIn the market the different manufacturers of variable frequency drives. You can see the variety of products of renowned companies, world-class ABB and SIMENS, and patterns of domestic production. The cost famous brands will be appropriate, but with regard to quality, then it is quite possible to meet and Russian firms.

Regarding the payback period, in each case it will be calculated individually. Usually the funds are fully covered by the savings over a period of six months to two years, but there may be isolated exceptions.

We can distinguish the following pattern — the more power the pump, the more it will cost, respectively, of the frequency and adjustable electric drive it will be more expensive than a less powerful counterpart. But this pump consumes more electricity — hence saving when using "chastotnik" will be more significant and it will pay for itself sooner.

Another fact: the installation of frequency-regulated electric drive will justify itself before the network, in which irregularity of work is more pronounced and the peaks (maximum load) are infrequent and of short duration.

In conclusion, we note that it would be good to apply such a method of regulation not only in the home. For many businesses this event on energy efficiency would help to reduce the energy intensity of production. Utilities would spend less on transporting water in heating systems and water supply.

Besides, the technology of frequency control is applicable not only to pumps. It can be used in any areas which use electric motors: elevators, lifts, any hydraulic components, mechanisms and other. Turning on rational use of electricity, we reduce the burden on CHP and nuclear power plants, which ultimately has a positive effect not only on the material condition of the state, but also on the ecology of the region. published

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: www.rmnt.ru/story/water/614881.htm#go-primenenie-chrjep-dlja-skvazhinnyh-nasosov

A considerable part of the electricity consumed in the movement of water and gases in such devices as pumps, fans, compressors. This equipment is used for the heating system, drinking water supply (not only centralized, but individual), functioning of the sewage, industrial moving liquids and gases.

In most cases, the energy here is spent irrationally. Due to the fact that consumption in these systems is uneven. It has peaks with a maximum load, which occupies a very small part of the time and rarely exceeding a couple of hours per day. It is these peaks and the calculated equipment such as a pump or blower. Basically you want 100% flow liquid or gas, and in the area of 30-40% of the maximum possible load. It is easy to see, for example, peaks of demand systems in Central drinking water supply: morning and evening high contrasted night minimum. However, the pump continues to operate at full capacity and to consume 100% energy.

To date, there is already a solution to this problem — variable frequency drive (CRAP), it will be discussed below.

Principles of regulation of the fluid flow without the use of CRAPto evaluate the benefits of frequency control, think about the commonly used traditional methods of reducing the flow of liquid or gas. For simplicity, the examples will be adduced in a normal water pipe with a standard pump, leaving aside the movement of air, oil, gas and various industrial liquids. By the way, the principles will be similar in many ways.

One of the first to examine the regulation by means of a bypass. This is a bypass line, which is an offshoot from the main pipe that returns part is pumped by the pump fluid back to the flow of the same pump. Despite the possibility of fairly precise adjustment of the system to the defined parameters of the water flow, the efficiency of her incredibly low.

Next on the list we can consider the regulation with valves and other devices installed between the pump and limiting the useful section of the pipeline. This option can also be viewed as a throwaway, a considerable part of the electricity is wasted as it creates a large pressure cut off these devices to the required level.

Another option regulation periodic operation of the pumps. It involves the inclusion of equipment only for filling tanks, battery water, after which there is an automatic stop. Of the above he has, perhaps, the best efficiency, however, is not without drawbacks:

- constant starts/stops reduce the life of the equipment;

- there is a risk of water hammer during the next launch, which could damage the pipeline;

- uneven pressure on the network.

The principle of regulation of fluid flow with application CRAPRegulation of fluid flow using variable frequency drives is designed to reduce the percentage of wasted energy in all areas where motors are used, and also has a variable load.

Such equipment includes not only the working mechanism of the pump and the motor. Here the main role plays the so-called "chastotnik", the frequency Converter. Through the established network of sensors, it reacts to changes and controls the feed: its output is formed a predetermined voltage with a particular amplitude, which, in turn, causes the motor and, accordingly, the operating mechanism of the pump to rotate with a certain (slow) speed. So when the flow rate increases to a peak pump will work with full dedication, but immediately when the decrease in demand will react by reducing the speed of rotation of the operating mechanism. And, accordingly, reduced energy consumption.

Therefore, the same volume of fluid delivered to the desired tap pump with CRAP, will require less money than use up a similar scheme with a constant speed of rotation of the working mechanism of the equipment. This allows you to abandon these ineffective management techniques like throttling or using by-passes.

Application CRAP for submersible pumpsAs mentioned above, in a typical country house, it is also possible to apply the technology of frequency control. It is possible to realize it in the hot water supply, heating, or downhole pump. The last option we consider in more detail, since that is where there is the most pronounced and understandable for the average person the frequency of load:

- night — at least, in this situation, often equal to zero;

- morning — max (wash, shower, making Breakfast etc.);

- day — medium (washing, cooking, cleaning);

- evening maximum (shower, bath, cooking and so on);

- night — at least once.

Today it is possible not only to buy ready made pump with adjustable drive, but retrofitting an already installed frequency Converter. The latter when used in conjunction with a downhole submersible pump should have the following set of features:

Built-in PID (sometimes PI, but these occur less often in the sale) regulator. The possibility of power optimization, allowing to reduce the normal voltage with a slight load on the actuator. The ability to re-start the drive after a fault or error of automation without human intervention. Motor protection against overload. Engine protection from overheating. The short circuit protection. Pump protection against running dry, i.e. without water in the fall of the level in the well below the suction pipe. The fluid is for unit cooling and lubrication, so its absence in the running pump can lead to overheating and rapid failure. The "sleep" mode when using the inverter in conjunction with a pump that has a limit to work at very low speeds. Archive of accidents. This option is indispensable for the clarification of the peculiarities of operation of the device in specific circumstances when repeated (periodic) outputs of the system. Scalar (volts-Hz U/f) or vector control for more precise adjustment of the actuator for normal smooth (without jerks).

With regard to equipment selection, we can highlight the following points:

When you select "chastotnik" should pay more attention not to power, and the rated current, and should provide for some margin. This is due to the fact that submersible motors nominal current is slightly higher than that of standard motors. Overload capacity installed "chastotnik" must be large enough (over 120%), otherwise, this deficiency must be compensated by the engine power, which will be somewhat higher. In cases where the transducer will be located in an unheated room, it must have the appropriate operating temperature range and suitable protection class. In addition to the main equipment should pay attention to the cable — it should be a big section in order to prevent voltage loss along the length. As additional protection you can install a motor choke, it further protects from large current leakage and tripping the overload protection. Before the inverter (Converter) you can also set a network throttle, he, in turn, will eliminate trouble from a distribution transformer.

Advantages CRAP in addition to energy savingsin Addition to saving energy equipment pumps adjustable electric drive has other positive side.

First, significantly, by almost half, increasing the life of equipment, as it reduces the number of starts and shutdowns.

Second, it is possible to significantly reduce the capacity of the storage tank, as the flow rate increases the pump automatically starts to work more efficiently. To any maximum consumption has not led to a reduction of pressure in the network, the installation can be provided in the pump with obviously more power — consumption of electricity will rise slightly.

Another positive factor is the smooth starts and stops, which negates the likelihood of water hammer in a network. As a result, not only the equipment, but also the water supply will last longer than usual.

Manufacturers and payback periodIn the market the different manufacturers of variable frequency drives. You can see the variety of products of renowned companies, world-class ABB and SIMENS, and patterns of domestic production. The cost famous brands will be appropriate, but with regard to quality, then it is quite possible to meet and Russian firms.

Regarding the payback period, in each case it will be calculated individually. Usually the funds are fully covered by the savings over a period of six months to two years, but there may be isolated exceptions.

We can distinguish the following pattern — the more power the pump, the more it will cost, respectively, of the frequency and adjustable electric drive it will be more expensive than a less powerful counterpart. But this pump consumes more electricity — hence saving when using "chastotnik" will be more significant and it will pay for itself sooner.

Another fact: the installation of frequency-regulated electric drive will justify itself before the network, in which irregularity of work is more pronounced and the peaks (maximum load) are infrequent and of short duration.

In conclusion, we note that it would be good to apply such a method of regulation not only in the home. For many businesses this event on energy efficiency would help to reduce the energy intensity of production. Utilities would spend less on transporting water in heating systems and water supply.

Besides, the technology of frequency control is applicable not only to pumps. It can be used in any areas which use electric motors: elevators, lifts, any hydraulic components, mechanisms and other. Turning on rational use of electricity, we reduce the burden on CHP and nuclear power plants, which ultimately has a positive effect not only on the material condition of the state, but also on the ecology of the region. published

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: www.rmnt.ru/story/water/614881.htm#go-primenenie-chrjep-dlja-skvazhinnyh-nasosov