454

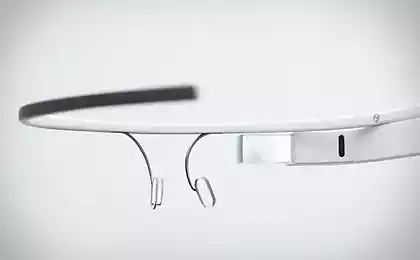

The new generation of screens will be made of the finest silver

Existing screens of smartphones and LCD panels are made of indium-tin oxide, but this material has several drawbacks. A new study proposes to use instead of ITO(indium tin oxide) screens of ultra-thin silver alloy.

Seventy two million two hundred twenty four thousand one hundred eighty eight

ITO (indium tin oxide) is a ceramic material that well conducts electricity and is thus completely transparent, making it a suitable material for the production of screens of all types, from smartphones to LCD TVs. But the indium is not recovered from the earth as ore, it is a by-product of processing metals and producing countries (e.g. USA) often have to import it from other countries. Of course, this burdens the industry a number of additional costs, and because researchers have more than ten years looking for a replacement for ITO, and finally they approached the solution of the problem: they will help the ultra-thin layer of silver.

It is not that indium insanely expensive, it's just his delivery is fixed, because as such the primary source of no. This explains Ioannis, Kymissis, associate Professor of electrical engineering at Columbia University. According to him, the main reason for the search — reducing the use of relatively scarce materials. Another important reason is that ITO is brittle, and therefore is not suitable for the production of flexible displays.

Jay Guo, Professor of electrical engineering and computer science at the University of Michigan, recently published a new study in the journal Advanced Materials, in which he proposed to use a film thickness of 7 nm of silver. Silver is also a great conductor of electricity, besides being so thin, completely transparent, has the necessary flexibility and toughness. In itself, the silver behaves quite headstrong and tries to form a structure, which he calls "Islands", but the problem managed to be solved thanks to alloy with copper or aluminum.

Six million three hundred seventy eight thousand four hundred thirty

The problem, as always, lies in the economy: manufacturing ITO put on an industrial footing, and therefore to oust it from the market the new material will not be easy. However, if the research Professor will find successful commercial implementation is possible in the near future we can expect new generation of screens. published

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: www.technology.org/2017/03/22/transparent-silver-tarnish-proof-films-for-flexible-displays-touch-screens-metamaterials/

Seventy two million two hundred twenty four thousand one hundred eighty eight

ITO (indium tin oxide) is a ceramic material that well conducts electricity and is thus completely transparent, making it a suitable material for the production of screens of all types, from smartphones to LCD TVs. But the indium is not recovered from the earth as ore, it is a by-product of processing metals and producing countries (e.g. USA) often have to import it from other countries. Of course, this burdens the industry a number of additional costs, and because researchers have more than ten years looking for a replacement for ITO, and finally they approached the solution of the problem: they will help the ultra-thin layer of silver.

It is not that indium insanely expensive, it's just his delivery is fixed, because as such the primary source of no. This explains Ioannis, Kymissis, associate Professor of electrical engineering at Columbia University. According to him, the main reason for the search — reducing the use of relatively scarce materials. Another important reason is that ITO is brittle, and therefore is not suitable for the production of flexible displays.

Jay Guo, Professor of electrical engineering and computer science at the University of Michigan, recently published a new study in the journal Advanced Materials, in which he proposed to use a film thickness of 7 nm of silver. Silver is also a great conductor of electricity, besides being so thin, completely transparent, has the necessary flexibility and toughness. In itself, the silver behaves quite headstrong and tries to form a structure, which he calls "Islands", but the problem managed to be solved thanks to alloy with copper or aluminum.

Six million three hundred seventy eight thousand four hundred thirty

The problem, as always, lies in the economy: manufacturing ITO put on an industrial footing, and therefore to oust it from the market the new material will not be easy. However, if the research Professor will find successful commercial implementation is possible in the near future we can expect new generation of screens. published

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: www.technology.org/2017/03/22/transparent-silver-tarnish-proof-films-for-flexible-displays-touch-screens-metamaterials/

Exercises for the prevention of cervical degenerative disc disease

Variable frequency drive guard energy savings