439

The geopolymers: environmentally friendly and more durable replacement of cement

Scientists Darmstadt technical University proposed an alternative to cement — geopolymeric material, not just more environmentally friendly, but also more resistant to chemicals and high temperatures.

When discussing environmental issues and greenhouse gas emissions one aspect, usually escapes attention: the use of cement in construction leads to greater emissions of CO2 than it releases, the entire air transport world.

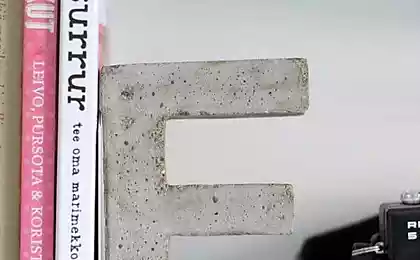

Professor Eddie Koenders and his group in an attempt to find an alternative cement applied to geopolymers. It dvuhmestnye system consisting of a reactive solid phase containing silicon oxide and aluminum oxide, and activation agent, alkali hydroxide, or liquid glass. The solid phase is the stones or minerals, hence the name root "geo". When the activation substance is mixed with crushed solid phase, it turns hard as a rock is an inorganic polymer.

Cement is made from limestone, clay and marl. The process is very energy intensive and leads to release of large quantities of carbon dioxide. The proportion of cement, more precisely, its production accounts for over 5% of global emissions.The term "geopolimer" was introduced by the French chemist Jose Davidowitz in the 70-ies of the last century. Then, these materials have not reached the mass market, but now, in connection with climate change, interest in them has increased.

Despite the fact that cement is the most widely used in construction material, geopolymers can compete with him. They are not only better from the environmental point of view, but also have the technical advantages: more resistant to high temperatures and chemicals and do not contain products of hydration, which dissolve under the influence of acids or other corrosive substances. It should also be mentioned that the geopolymers requires only one day to purchase the same resistance to compressive loads as high quality cement.

Now scientists at the University of Dortmund working on the creation of sewer pipes of geopolymers that are resistant to biochemicals, and are going to start the geopolymers into mass production as quickly as possible. Flexible and durable concrete mix produced scientists of Singapore. Cement boards based on it are characterized by low weight, strength and flexibility. The development will allow to reduce the installation time by covering twice. published

Source: hightech.fm/2017/01/18/geopolymer

When discussing environmental issues and greenhouse gas emissions one aspect, usually escapes attention: the use of cement in construction leads to greater emissions of CO2 than it releases, the entire air transport world.

Professor Eddie Koenders and his group in an attempt to find an alternative cement applied to geopolymers. It dvuhmestnye system consisting of a reactive solid phase containing silicon oxide and aluminum oxide, and activation agent, alkali hydroxide, or liquid glass. The solid phase is the stones or minerals, hence the name root "geo". When the activation substance is mixed with crushed solid phase, it turns hard as a rock is an inorganic polymer.

Cement is made from limestone, clay and marl. The process is very energy intensive and leads to release of large quantities of carbon dioxide. The proportion of cement, more precisely, its production accounts for over 5% of global emissions.The term "geopolimer" was introduced by the French chemist Jose Davidowitz in the 70-ies of the last century. Then, these materials have not reached the mass market, but now, in connection with climate change, interest in them has increased.

Despite the fact that cement is the most widely used in construction material, geopolymers can compete with him. They are not only better from the environmental point of view, but also have the technical advantages: more resistant to high temperatures and chemicals and do not contain products of hydration, which dissolve under the influence of acids or other corrosive substances. It should also be mentioned that the geopolymers requires only one day to purchase the same resistance to compressive loads as high quality cement.

Now scientists at the University of Dortmund working on the creation of sewer pipes of geopolymers that are resistant to biochemicals, and are going to start the geopolymers into mass production as quickly as possible. Flexible and durable concrete mix produced scientists of Singapore. Cement boards based on it are characterized by low weight, strength and flexibility. The development will allow to reduce the installation time by covering twice. published

Source: hightech.fm/2017/01/18/geopolymer

Insulation of floor in a wooden house

The strengthening of the walls of the drain groove: five best ways