431

The new formula of cement will reduce by half its CO2 emissions and increase strength

The cement most commonly used in the world building material, and one of the leading contributors to global warming. 10 emissions of industrial greenhouse gases generated in its production. A new study suggests how these emissions can be reduced by more than half and will make it more durable.

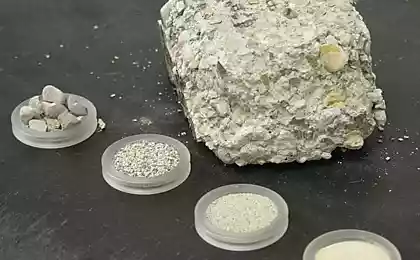

Such conclusions were made after the detailed molecular analysis of the complex structure of concrete, which is a mixture of sand, gravel, water and cement.

Cement is made by joining calcium-rich material, usually limestone, with silica — rich material- typically clay, in the processing of high temperatureto 1500 degrees Celsius gives a hard mass called "clinker". The decarbonization of limestone and the heating of cement will provide a large part of greenhouse gas emissions.

New analysis shows that the decrease in the ratio of calcium to silicate can not only reduce these emissions but also to increase the strength of concrete.

In modern construction the use of concrete is estimated at three times more than steel.

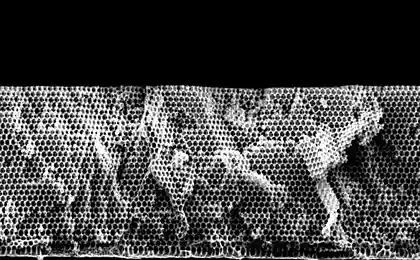

In conventional cements, the ratio of calcium to silica can range from about 1.2 to 2.2, with a coefficient of 1.7 accepted as standard. But in the past no details have not compared the molecular structure. Researchers from MIT have built a database of all these chemical formulations, finding that the optimal ratio should be about 1.5. It is in their opinion "will double the resistance of the cement and increase its resistance to cracking" at the same time reducing carbon emissions can be reduced up to 60 percent.

In addition to the General improvements of mechanical strength, this material would be more glassy and less crystalline, which "may reduce the residual stresses in the material and make it more paramoecium".

This work is the culmination of 5 years of research joint team from mit and CNRS.

How do you think the researchers of the new formula may be of particular interest to the oil and gas industry, where cement around the casing is critical to prevent leaks and breakthroughs.

While work remains at the molecular level of analysis, then the case for experimental building at the engineering scale, the construction of infrastructure, housing and other purposes.

Source: rodovid.me

Such conclusions were made after the detailed molecular analysis of the complex structure of concrete, which is a mixture of sand, gravel, water and cement.

Cement is made by joining calcium-rich material, usually limestone, with silica — rich material- typically clay, in the processing of high temperatureto 1500 degrees Celsius gives a hard mass called "clinker". The decarbonization of limestone and the heating of cement will provide a large part of greenhouse gas emissions.

New analysis shows that the decrease in the ratio of calcium to silicate can not only reduce these emissions but also to increase the strength of concrete.

In modern construction the use of concrete is estimated at three times more than steel.

In conventional cements, the ratio of calcium to silica can range from about 1.2 to 2.2, with a coefficient of 1.7 accepted as standard. But in the past no details have not compared the molecular structure. Researchers from MIT have built a database of all these chemical formulations, finding that the optimal ratio should be about 1.5. It is in their opinion "will double the resistance of the cement and increase its resistance to cracking" at the same time reducing carbon emissions can be reduced up to 60 percent.

In addition to the General improvements of mechanical strength, this material would be more glassy and less crystalline, which "may reduce the residual stresses in the material and make it more paramoecium".

This work is the culmination of 5 years of research joint team from mit and CNRS.

How do you think the researchers of the new formula may be of particular interest to the oil and gas industry, where cement around the casing is critical to prevent leaks and breakthroughs.

While work remains at the molecular level of analysis, then the case for experimental building at the engineering scale, the construction of infrastructure, housing and other purposes.

Source: rodovid.me