428

New Li-ion battery is created from 100% silicon

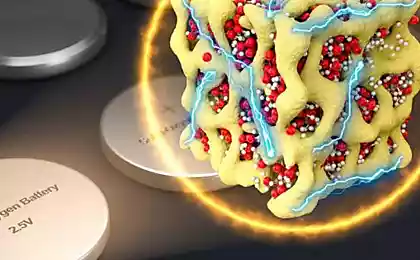

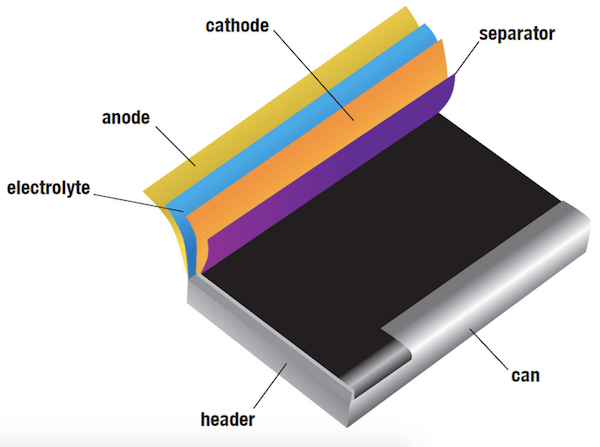

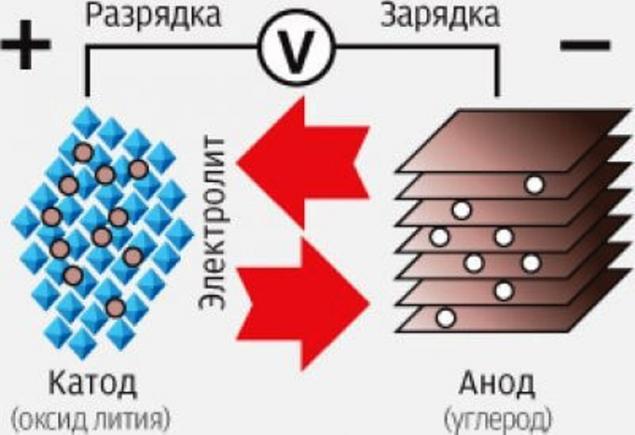

Dutch startup called LeydenJar made a move to the area in which it has never dared to look. The company received funds from the energy research centre of the Netherlands on the development of a new lithium-ion battery pack, which uses 100% silicon instead of graphite.

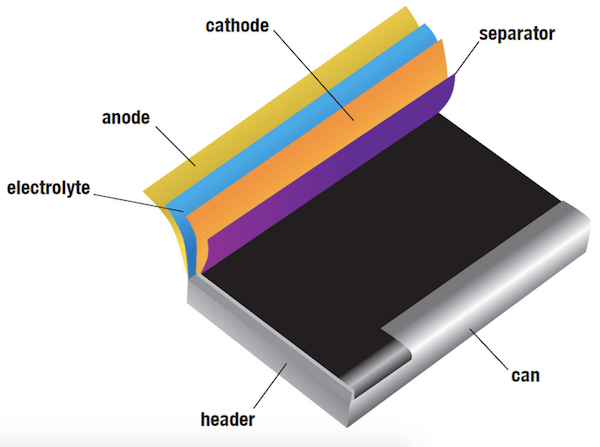

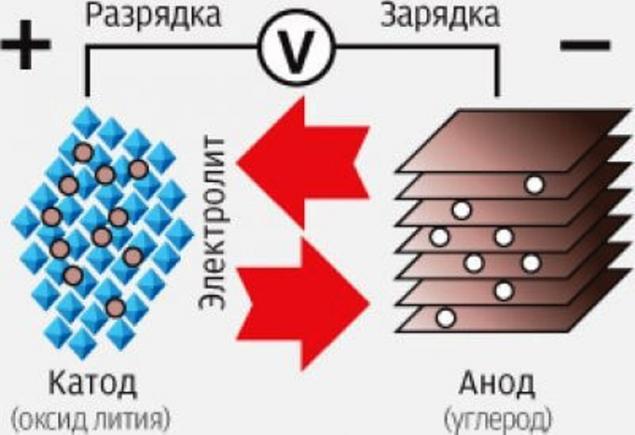

At first glance, it's risky, because the silicon goes through destructive cycles of compression and expansion when used in batteries. However, if a new battery to produce at scale and with good life expectancy, then the effect will be a capacity increase of 50% compared to a conventional battery based on graphite.

The help of nanotechnology

In such applications, the silicon, according to experts LeydenJar 10 times increases the capacity of the anode in the battery.

They managed to create an anode using only the plasma device. The silicon is deposited on the copper substrate in monomernye columns, reaching a height of about 10 microns (this thickness of the layer required for commercial applications, according to requirements specification LeydenJar).

The sample is partially filled and partially void provides ample space for safe expansion of silicon during charging of the battery.

Currently the band is working on a plant project that will be able to produce in large quantity a new anode for lithium-ion batteries. Commissioning of the plant expected by end of 2018. published

materials cleantechnica.com

Source: /users/14592

At first glance, it's risky, because the silicon goes through destructive cycles of compression and expansion when used in batteries. However, if a new battery to produce at scale and with good life expectancy, then the effect will be a capacity increase of 50% compared to a conventional battery based on graphite.

The help of nanotechnology

In such applications, the silicon, according to experts LeydenJar 10 times increases the capacity of the anode in the battery.

They managed to create an anode using only the plasma device. The silicon is deposited on the copper substrate in monomernye columns, reaching a height of about 10 microns (this thickness of the layer required for commercial applications, according to requirements specification LeydenJar).

The sample is partially filled and partially void provides ample space for safe expansion of silicon during charging of the battery.

Currently the band is working on a plant project that will be able to produce in large quantity a new anode for lithium-ion batteries. Commissioning of the plant expected by end of 2018. published

materials cleantechnica.com

Source: /users/14592