484

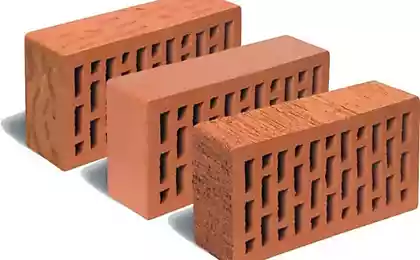

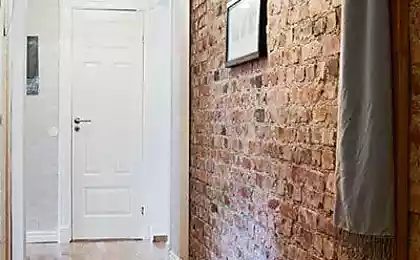

Bricks from paper waste

Our world is inconceivable without paper. Its production takes a huge amount of trees, besides, it is accompanied by considerable waste. Processing of this waste will enable more efficient use of wood and to reduce the burden on the environment.

A recent study of Spanish scientists proves that the waste paper industry might become a valuable raw material and to generate revenues. The results of the work of scientists from the Polytechnic school of Linares, University of Jaén and published in the journal "Technology of fuel" (Fuel Processing Technology).

The scientists gathered cellulose waste that has accumulated on the paper mill. In this case we are talking about the sludge formed during cleaning of industrial wastewater. It was mixed with clay. From the resulting material by means of extrusion squeezed out one long "sausage". Then it was cut into separate bricks and burned them in the furnace.

According to the researchers, burning them bricks it took much less time, and thus energy, than the traditional production of clay brick, because of the composition of the mixture. If the method comes to industrial use, the reduction in processing time will result in a considerable saving of energy and costs in General. In addition, scientists obtained the bricks are less thermal conductivity, leading to improved thermal insulation properties of buildings are built.

Broad use of a permanent waste paper production not only has undeniable environmental benefits, but also will allow to optimize the consumption of clay, to preserve it for other purposes or at least to increase the time of development of the explored natural resources.

Currently, lab line capable of producing only small blocks of size 3х1х6 see This is sufficient for studies of the properties of the material. However, the team tried to produce and test larger samples, suitable for use in construction. The results of their tests are similar to those shown in laboratory prototypes.

According to co-author studies Carmen martínez from the University of Jaen: "In General, this method can save energy and raw materials for bricks, even if we ignore the environmental benefits from the recovery of wastes".

However, the researchers acknowledge that "Achilles heel" of the invention is their low mechanical strength. Its indicators are within the norms, but they are lower than the characteristics of traditional bricks.

The research team continues to work. Scientists hope to find a reasonable balance between environmental benefits and durability of a material by applying various additives, including waste from other industries. In particular, the attention of researchers is attracted by the waste water treatment, brewing, production of olive oil and biofuels.

Source: /users/104

A recent study of Spanish scientists proves that the waste paper industry might become a valuable raw material and to generate revenues. The results of the work of scientists from the Polytechnic school of Linares, University of Jaén and published in the journal "Technology of fuel" (Fuel Processing Technology).

The scientists gathered cellulose waste that has accumulated on the paper mill. In this case we are talking about the sludge formed during cleaning of industrial wastewater. It was mixed with clay. From the resulting material by means of extrusion squeezed out one long "sausage". Then it was cut into separate bricks and burned them in the furnace.

According to the researchers, burning them bricks it took much less time, and thus energy, than the traditional production of clay brick, because of the composition of the mixture. If the method comes to industrial use, the reduction in processing time will result in a considerable saving of energy and costs in General. In addition, scientists obtained the bricks are less thermal conductivity, leading to improved thermal insulation properties of buildings are built.

Broad use of a permanent waste paper production not only has undeniable environmental benefits, but also will allow to optimize the consumption of clay, to preserve it for other purposes or at least to increase the time of development of the explored natural resources.

Currently, lab line capable of producing only small blocks of size 3х1х6 see This is sufficient for studies of the properties of the material. However, the team tried to produce and test larger samples, suitable for use in construction. The results of their tests are similar to those shown in laboratory prototypes.

According to co-author studies Carmen martínez from the University of Jaen: "In General, this method can save energy and raw materials for bricks, even if we ignore the environmental benefits from the recovery of wastes".

However, the researchers acknowledge that "Achilles heel" of the invention is their low mechanical strength. Its indicators are within the norms, but they are lower than the characteristics of traditional bricks.

The research team continues to work. Scientists hope to find a reasonable balance between environmental benefits and durability of a material by applying various additives, including waste from other industries. In particular, the attention of researchers is attracted by the waste water treatment, brewing, production of olive oil and biofuels.

Source: /users/104