433

The Spaniards learned how to make bricks from waste paper

Paper waste is already used to create several useful things in the economy. Craftsmen create from recycled cardboard bicycles and canoes. Many companies strive to minimize the use of paper, as the same Disney that refused the paper from "dirty" sources. Xerox also decided to contribute to the minimisation of volumes of felling of forests for purposes of pulp and paper industry — the company creates technology to reuse the paper. Just recently, Spanish scientists decided to give the paper strength, so that she could be used in construction.

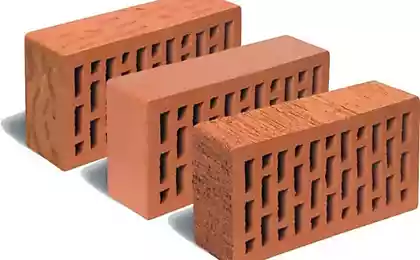

A team of researchers from the University of jaén decided to create from recycled materials are the real bricks. It is reported that the technology of production of building materials from waste paper still needs a bit of refinement before the bricks are ready for use for its intended purpose, but ultimately new products can bypass traditional counterparts in terms of the ratio quality / price.

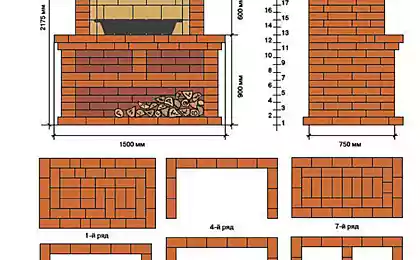

Spanish scientists collect the pulp waste from a local pulp and paper mill, as well as sludge (sediment in the tank waste-water) remaining after wastewater treatment at the plant. Then these substances are mixed with clay used in construction. Scientists put the compound under pressure, and then extruded. It turns out the long tape, which is subsequently cut into bricks. Then an unusual building materials are fired in a kiln for firing and drying.

According to the researchers, the bricks do not need to burn as long as with their traditional counterparts. This is due to the content of the paper. If the Spaniards succeed in establishing commercial production of a new product named above feature of the manufacturing process will result in significant energy savings and, consequently, production costs.

After adding a material of paper, scientists have discovered another interesting property of the finished product: bricks have very low thermal conductivity. This means that they will have good insulating properties when used in structural elements of buildings.

Eco-activists remind that throw waste paper is necessary in special tanks. In addition, the use of cellulose waste will help to reduce the burden on landfills, and manufacturers of building materials who license the new technology, will be able to more effectively use their reserves of clay.

The Spaniards started the production of relatively small bricks. Their dimensions are 3 x 1 x 6 cm larger counterparts was also created with the purpose of carrying out tests, and, reportedly, they have a comparable level of quality. Unfortunately, the mechanical strength is still relatively low. Although it is still above the specified building regulations minimum, but traditional brick is not.

Scientists hope to overcome this limitation. Perhaps this will be achieved by introducing into a compound of additional elements: waste from Breweries, factories for the production of olive oil or enterprises engaged in the production of biofuels. By the way, researchers from the University of Spain in Seville and the University of Strathclyde in Glasgow, Scotland, have carried out experiments to create such bricks that partially consisted of sheep's wool (waste).

Photo and video: University of Jaen ©

Source: energysafe.ru/

A team of researchers from the University of jaén decided to create from recycled materials are the real bricks. It is reported that the technology of production of building materials from waste paper still needs a bit of refinement before the bricks are ready for use for its intended purpose, but ultimately new products can bypass traditional counterparts in terms of the ratio quality / price.

Spanish scientists collect the pulp waste from a local pulp and paper mill, as well as sludge (sediment in the tank waste-water) remaining after wastewater treatment at the plant. Then these substances are mixed with clay used in construction. Scientists put the compound under pressure, and then extruded. It turns out the long tape, which is subsequently cut into bricks. Then an unusual building materials are fired in a kiln for firing and drying.

According to the researchers, the bricks do not need to burn as long as with their traditional counterparts. This is due to the content of the paper. If the Spaniards succeed in establishing commercial production of a new product named above feature of the manufacturing process will result in significant energy savings and, consequently, production costs.

After adding a material of paper, scientists have discovered another interesting property of the finished product: bricks have very low thermal conductivity. This means that they will have good insulating properties when used in structural elements of buildings.

Eco-activists remind that throw waste paper is necessary in special tanks. In addition, the use of cellulose waste will help to reduce the burden on landfills, and manufacturers of building materials who license the new technology, will be able to more effectively use their reserves of clay.

The Spaniards started the production of relatively small bricks. Their dimensions are 3 x 1 x 6 cm larger counterparts was also created with the purpose of carrying out tests, and, reportedly, they have a comparable level of quality. Unfortunately, the mechanical strength is still relatively low. Although it is still above the specified building regulations minimum, but traditional brick is not.

Scientists hope to overcome this limitation. Perhaps this will be achieved by introducing into a compound of additional elements: waste from Breweries, factories for the production of olive oil or enterprises engaged in the production of biofuels. By the way, researchers from the University of Spain in Seville and the University of Strathclyde in Glasgow, Scotland, have carried out experiments to create such bricks that partially consisted of sheep's wool (waste).

Photo and video: University of Jaen ©

Source: energysafe.ru/