209

Secrets of the right choice of thermal insulation for pipelines

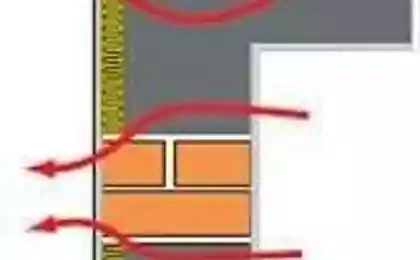

The main objective of thermal insulation materials for pipelines is to exclude heat exchange between the equipment or transported product (agent) and the environment. The almost universal use of these materials is dictated primarily by the requirements of economy and energy saving.

To implement this function allows the microporous structure of insulation, thanks to which the thermal conductivity of the material is significantly reduced.

The most important property of thermal insulation materials - thermal conductivity - is characterized by the coefficient of thermal conductivity. This parameter shows the leakage of energy through the insulation layer per unit time, depending on the difference in temperature of the external environment and the insulated surface. The lower this coefficient - the more effective the thermal insulator.

Thermal insulation materials, depending on the operating conditions, must have some additional properties:

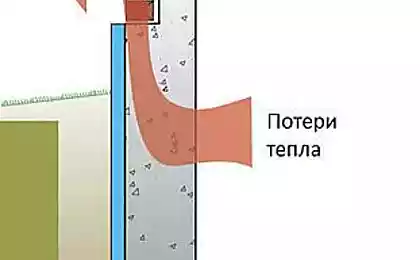

Wet resistance. The accumulation of moisture in the structure of the insulation causes a significant deterioration in thermal insulation properties, and also contributes to the rapid development of corrosion of the material of the pipeline or equipment. Surface protection from condensation. This property must have thermal insulation, which is used on pipelines transporting cold liquids or in a ventilation device. To fully ensure this ability, the vapor permeability of the material should be as low as possible.

In addition, installation work should be carried out especially qualitatively, the joints of the thermal insulation coating should be sealed with vapor-tight material. The most optimal thermal insulation materials for such conditions are polymers: foamed polyethylene or rubber. Fire resistance. If the company has special requirements for fire safety, it is necessary to use either non-combustible materials, or corresponding to a certain class of fire danger. In such cases, preference is given to thermal insulation from basalt fibers or foam glass. Resistance to high temperatures. It is necessary in cases where the insulated surface has a high temperature (up to 700 degrees). As a rule, such surfaces are insulated with materials based on basalt fiber. High electrical resistance. The thermal insulation product must protect the material of the insulated surface from wandering electric currents that can provoke electrical corrosion of the metal. Resistance to rotting. The insulation must be resistant to microorganisms, rodents and insects. Also, it should not decompose with the formation of aggressive substances that can damage the material of the insulated surface. Mineral insulators (minwat) Very versatile and affordable material that has been used for several decades. It has high fire resistance. Depending on the brand, the density coefficient of thermal conductivity varies from 0.044 - 0.049 W / (m*degree) at a temperature of 25 degrees to 0.067 - 0.072 W / (m*degree) at a temperature of 125 degrees.

Insulation based on basalt fiber The coefficient of thermal conductivity of these materials is in the same range as mineral wool. Basalt fiber insulation is highly reliable and durable, almost unaffected by the environment. It is characterized by a high service life - up to 50 years.

Glass wool is also quite common material. The coefficient of thermal conductivity also depends on the density and ranges from 0.041 to 0.074 W/(m*degree).

Volcanite thermal insulation products are obtained by mixing diatomite, quicklime and asbestos. The coefficient of thermal conductivity leaves at 25 degrees is 0.077 W / (m*degrees), at 125 degrees - 0.1 W / (m*degrees).

Lime-silicon insulation Porous materials with a coefficient of thermal conductivity from 0.058 W / (m*degree) at 25 degrees to 0.077 at 125 degrees.

Perlite-based materials are produced by thermal treatment of volcanic glass. The coefficient of thermal conductivity ranges from 0.058 at 25 degrees to 0.128 at 300 degrees.

The cost of this type of heat insulator is justified by a high service life. The material is characterized by high moisture resistance. The coefficient of thermal conductivity is 0.044-0.046 W/(m*degree). A characteristic disadvantage: the material burns with the release of toxic substances.

Polymers (foamed polyethylene and synthetic rubber) Reliable sealed thermal insulation material, capable of operating in a fairly wide range of temperatures, is resistant to rotting and aggressive environments. The thermal conductivity coefficient is 0.039 W/(m*degree) for polyethylene and 0.036 W/(m*degree) for rubber. Products made of foamed polyethylene attract their affordable cost and ease of installation. The disadvantages of synthetic rubber include the high cost.

Source: greenvolt.ru/

To implement this function allows the microporous structure of insulation, thanks to which the thermal conductivity of the material is significantly reduced.

The most important property of thermal insulation materials - thermal conductivity - is characterized by the coefficient of thermal conductivity. This parameter shows the leakage of energy through the insulation layer per unit time, depending on the difference in temperature of the external environment and the insulated surface. The lower this coefficient - the more effective the thermal insulator.

Thermal insulation materials, depending on the operating conditions, must have some additional properties:

Wet resistance. The accumulation of moisture in the structure of the insulation causes a significant deterioration in thermal insulation properties, and also contributes to the rapid development of corrosion of the material of the pipeline or equipment. Surface protection from condensation. This property must have thermal insulation, which is used on pipelines transporting cold liquids or in a ventilation device. To fully ensure this ability, the vapor permeability of the material should be as low as possible.

In addition, installation work should be carried out especially qualitatively, the joints of the thermal insulation coating should be sealed with vapor-tight material. The most optimal thermal insulation materials for such conditions are polymers: foamed polyethylene or rubber. Fire resistance. If the company has special requirements for fire safety, it is necessary to use either non-combustible materials, or corresponding to a certain class of fire danger. In such cases, preference is given to thermal insulation from basalt fibers or foam glass. Resistance to high temperatures. It is necessary in cases where the insulated surface has a high temperature (up to 700 degrees). As a rule, such surfaces are insulated with materials based on basalt fiber. High electrical resistance. The thermal insulation product must protect the material of the insulated surface from wandering electric currents that can provoke electrical corrosion of the metal. Resistance to rotting. The insulation must be resistant to microorganisms, rodents and insects. Also, it should not decompose with the formation of aggressive substances that can damage the material of the insulated surface. Mineral insulators (minwat) Very versatile and affordable material that has been used for several decades. It has high fire resistance. Depending on the brand, the density coefficient of thermal conductivity varies from 0.044 - 0.049 W / (m*degree) at a temperature of 25 degrees to 0.067 - 0.072 W / (m*degree) at a temperature of 125 degrees.

Insulation based on basalt fiber The coefficient of thermal conductivity of these materials is in the same range as mineral wool. Basalt fiber insulation is highly reliable and durable, almost unaffected by the environment. It is characterized by a high service life - up to 50 years.

Glass wool is also quite common material. The coefficient of thermal conductivity also depends on the density and ranges from 0.041 to 0.074 W/(m*degree).

Volcanite thermal insulation products are obtained by mixing diatomite, quicklime and asbestos. The coefficient of thermal conductivity leaves at 25 degrees is 0.077 W / (m*degrees), at 125 degrees - 0.1 W / (m*degrees).

Lime-silicon insulation Porous materials with a coefficient of thermal conductivity from 0.058 W / (m*degree) at 25 degrees to 0.077 at 125 degrees.

Perlite-based materials are produced by thermal treatment of volcanic glass. The coefficient of thermal conductivity ranges from 0.058 at 25 degrees to 0.128 at 300 degrees.

The cost of this type of heat insulator is justified by a high service life. The material is characterized by high moisture resistance. The coefficient of thermal conductivity is 0.044-0.046 W/(m*degree). A characteristic disadvantage: the material burns with the release of toxic substances.

Polymers (foamed polyethylene and synthetic rubber) Reliable sealed thermal insulation material, capable of operating in a fairly wide range of temperatures, is resistant to rotting and aggressive environments. The thermal conductivity coefficient is 0.039 W/(m*degree) for polyethylene and 0.036 W/(m*degree) for rubber. Products made of foamed polyethylene attract their affordable cost and ease of installation. The disadvantages of synthetic rubber include the high cost.

Source: greenvolt.ru/