683

Energy saving with blinds and curtains

The increase in electricity prices and the desire to reduce carbon dioxide emissions have made energy savings for heating and cooling of residential and office buildings worldwide need. In many countries the main method of reducing energy consumption is the energy rehabilitation of buildings. It is necessary to evaluate and perform various technical and design capabilities, and to identify the solution that is most profitable from an economic point of view.

In addition to classical and well-known in the market for methods such as replacement Windows and providing better insulation of the external walls, intermediate floors and roofs, significantly improve the thermal insulation of the building helps the installation of shutters. First of all it concerns the countries with a continental climate characterized by cold winters and hot summers, and regions with low clouds.

Here shutters, sliding or hinged shutters will be doubly useful. As a means of temporary insulation on a cold winter night, they reduce the costs for heating and in summer as an effective sun screens reduce the need for air conditioning facilities. This article explains what design aspects of roller shutters it is necessary to consider how high the potential savings of electricity.

Physical and technical aspects

Under certain conditions, systems of internal and external sun protection, which are in accordance with EN 13659 shutters, sliding shutters, blinds and textile systems installed on transparent surfaces (Windows and glazed area), a cold night can be a means of thermal insulation. During the day they are applied seldom enough, as the residents of the houses prefer to use natural daylight and have visual contact with the outside world. To accurately calculate potential energy savings, it is necessary to take into account the various factors affecting a building. According to EN ISO 13790 imitation of such factors is based on the model of one room (DIN EN ISO 13791). This simplifies the process of identifying potential energy savings. In General, the effectiveness of the system of temporary insulation of the greatest influence have the following factors.

Airtightness of the system (static air layer and the thermal resistance according to EN 13125). The rate of thermal insulation systems (resistance to heat and radiation for infrared reflective coatings). The level of insulation of external walls and Windows/glazing. Climatic conditions (daylength and ambient temperature during the heating period). View of the control system and the time required to close the system (at certain hours or according to the length of a day). Indicator of the potential saving relates to an area of the window as all the factors equally affect both the Windows and system temporary insulation, and the improvement of the physical and technical characteristics of the restricted area of the transparent surface.

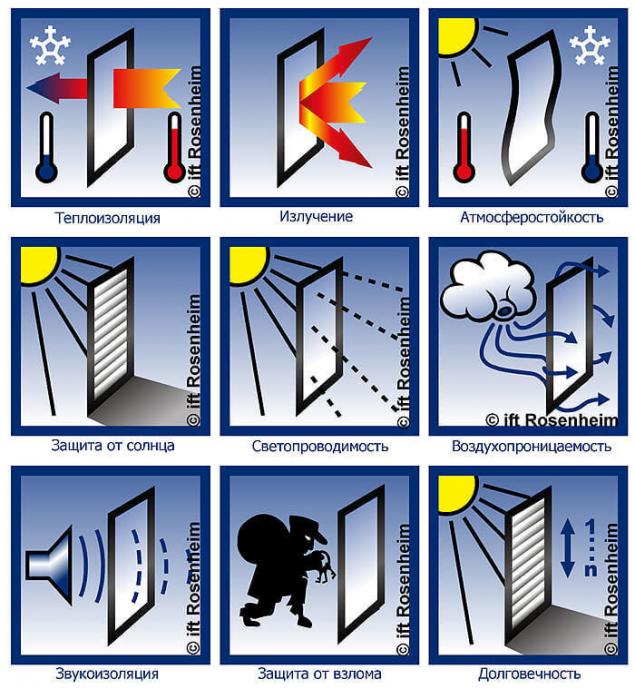

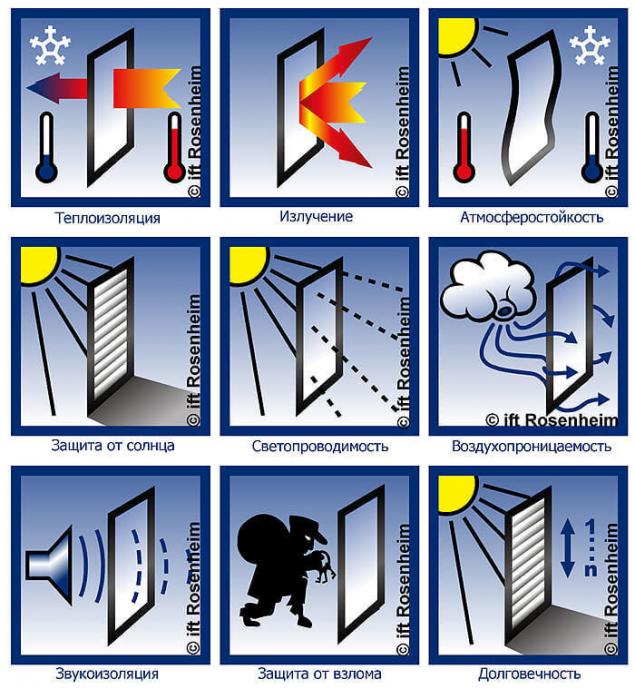

Fig.1. Important factors that affect the system temporary insulation

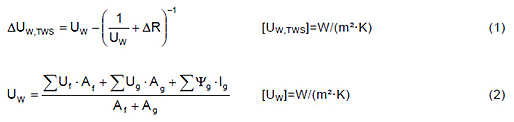

The heat transfer coefficient Uw

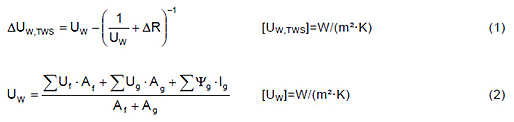

To accurately assess the potential energy efficiency of buildings should take into account climatic data, the design of the building, Windows and heating equipment. The buyer this information is usually unknown, and for fast evaluation, it is too time-consuming. For this reason, it is also important to consider the decrease in heat transfer coefficient ΔUw – parameter, well known to architects, manufacturers and builders. However, to directly determine the rate of potential energy saving in this case is impossible, since the heat transfer coefficient decreases only when use of a temporary insulation. To determine the temperature of the inner surface of the indicator ΔUw,tws (decrease of heat transfer coefficient of the window system temporary insulation), of course, of great importance. Below are calculations for systems external solar shading installed on the standard size according to EN 14351-1: of 1.23×1.48 m, the proportion of the window frames 30%.

Uw – heat transfer coefficient of Windows, W/(m2•K)

Uf – thermal transmittance of the window frame, W/(m2•K)

Ug – thermal transmittance coefficient of the glazing, W/(m2•K)

Af – area of the window frame, m2

Aw is the window area, m2 (AF + Ad)

Ag – area of glazing, m2

lg – the length of the perimeter connections of the glazing to the profile, m

Ψg is the linear heat transfer coefficient, W/(m•K)

ΔR is the resistance to heat transfer of the external sun protection, (m2•K)/W

ΔUw,tws is the reduction of heat transfer coefficient of Windows with sun screens, W/(m2•K).

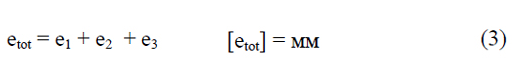

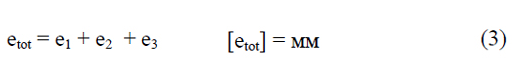

Reducing heat transfer through the system temporary insulation depends on the thermal resistance of the external sun protection ΔR, which is significantly affected by the permeability of the system and the rate of thermal insulation. The total value of clearances etot (side, top and bottom) is calculated according to the following formula:

Depending on the indicator etot of the system of external solar shading are divided into five classes according to EN 13125 (table. 2). The highest level of air tightness (class 5) is achieved in the case when rolling the canvas, no air and light gaps (slats abut each other or located lapped), and the total value of clearances between the system and external solar shading external wall, window or façade is less than 3 mm. air Permeability according to EN 13125 presented in table 1, the exact figures are measured based on the provisions of EN 12835. Standard EN 13125 establishes the minimum airtightness classes for specific designs. For example, folding shutters (accordion) meet 1st class, RAF-curtains with the United or fixed lamellas in the closed position — 2nd class.

Table 1. Classes of air permeability according to EN 13125

Class

Feature

etot

ΔR in (m2·K)/W

1

The high breathability

>35 mm

ΔR = 0,08

2

High breathability

15-35 mm

ΔR = 0,25 xRsh + 0,09

3

Average breathability

8-15 mm

ΔR = 0,55 xRsh + 0,11

4

Low permeability

3-8 mm

ΔR = xRsh 0,80 + 0,14

5

Airtight system

<3 mm

ΔR = 0,95 xRsh + 0,17

The heat resistance coefficient rolling canvas Rsh or other exterior sun protection shall be specified by the supplier. It is determined by tests using thermal chambers according to EN ISO 12567-1 or calculated according to EN ISO 10077-2 and must be specified with a precision to hundredths. Both studies are conducted in the Institute of window technology (Rosenheim). Applied to the system of internal solar infrared reflective coating is taken into account through the index k, which depends on the emissivity ε of the coating and multiplied by ΔR.

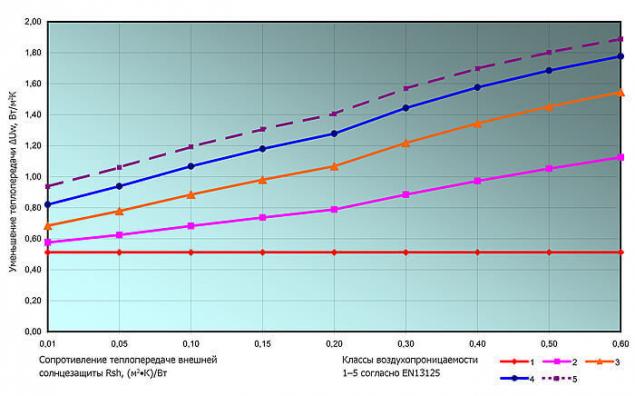

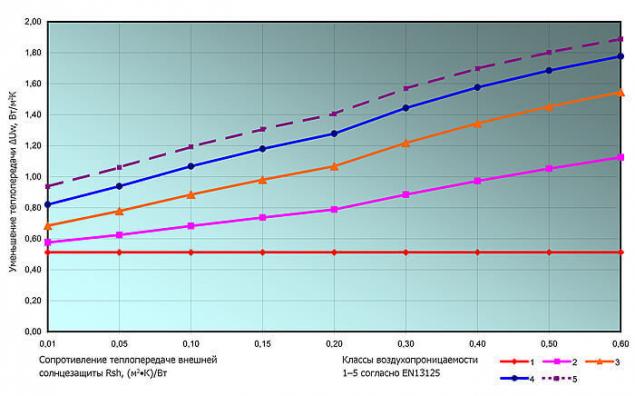

Fig. 2. The decrease in heat transfer coefficient ΔUw in W/(m2•K) for Windows with Uw = 2.8 W/(m2•K) temporary insulation, depending on the heat resistance of rolling cloth and Rsh class of air tightness according to EN 13125

System design

The system design of the temporary heat protection (shutters, blinds, etc.) should not only increase the insulation, but also to perform several other important functions: to protect from the sun, hacking, heavy rain, hail and wind. On the rate of thermal insulation protection systems influence thermal resistance of the material (rolling blade) and airtightness. To the greatest extent the tightness of the joint system of external sun protection and temporary insulation on exterior wall, window or façade: between the time system of insulation and window needs to form a static air layer.

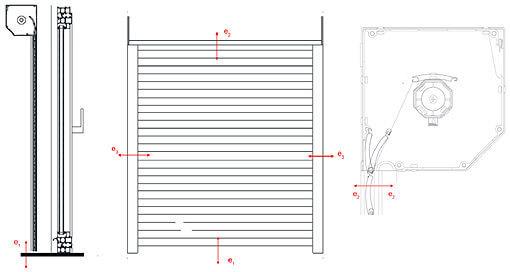

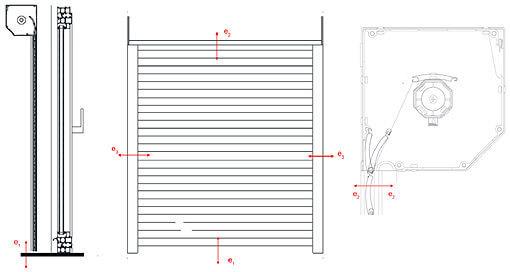

Fig. 3. The distribution of gaps according to EN 13125 (photo ALUTECH group of companies, the test Report of the ift No. 11-000216-PR03)

Reduce the heat loss when applying an infrared reflective coating for internal sun protection is subject to the following conditions.

Layer infrared-reflecting coating applied to the weak convection, as a rule, on the side facing the window. Best on buildings with low insulation". Protect coating from contamination". The coating is protected from damage during cleaning or operation. In the system of external solar shading of the infrared reflective coating may not be taken into account according to EN 13125, as well as due to contamination during operation.

Example of calculation

The definition of a possible decrease in heat transfer coefficient Uw is shown in the example window shutters made of aluminium. This design also provides more reliable protection against burglary. Used to calculate roll system RS.AR41 ALUTECH group of companies (see test report of the ift No. 11-000216-PR03).

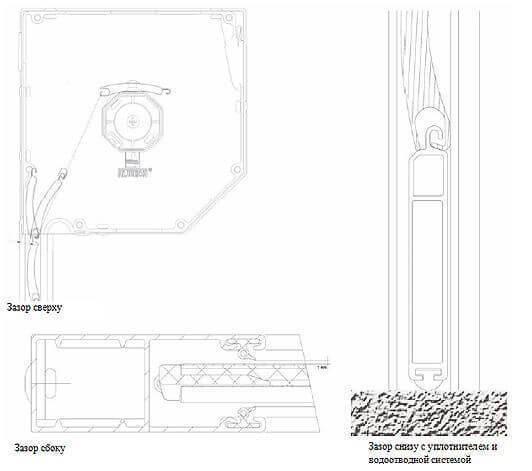

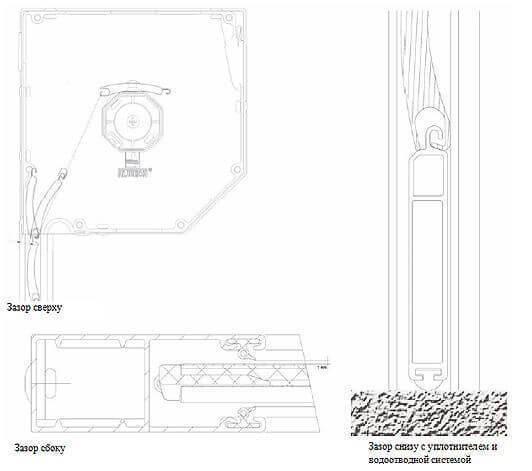

Fig. 4. The joints and gaps, providing 4th class of air tightness according to EN 13125 (drawings ALUTECH group of companies from the test report of the ift No. 11-000216-PR03)

Product description and parameters

Roll system consisting of a rolling cloth with end profile, roller shutter boxes, side rail and bottom of the tire as a frame. Aluminium profile filled with polyurethane foam. Bus and terminal profiles made of aluminum have a sealing insert made of EPDM. Design of roller shutter boxes seals does not provide.

The size of the gap between the rolling blade and boxes or building blocks:

the clearance from bottom 0 mm

the clearance from the top – 5 mm

the clearance on the sides (left and right) – 1 mm

Rsh = 0,02 in (m2•K)/W

The calculation of the additional resistance to heat transfer

The distribution on classes of air permeability according to EN 13125:

the clearance from below: e1 = 0 mm

the clearance from the top: e2 = 5 mm

the clearance from the side: e3 = 1 mm

the total value of clearances: etot = e1 + e2 + e3 = 6 mm

Air and light gaps in rolling the canvas out of the slats abut each other. In accordance with the requirements to the 4th class of air permeability according to EN 13125 total value of clearances etot must be ≤ 8 mm. In this case, the above construction corresponds to the 4th class according to EN 13125.

Additional thermal resistance ΔR when Rsh = 0,02 in (m2•K)/W is calculated when tested by the method of thermal imaging cameras as follows (see table. 1):

ΔR = 0,8 × Rsh + 0,14 = 0,8 × 0,02 in (m2•K)/W + 0,14 = 0,16 (m2•K)/W

When installing temporary insulation in the old window (Uw = 2.8 W/(m2•K)) reduction of heat transfer is about 0.85 W/(m2•K), and when you install such a system on a modern window according to the decree on energy efficiency of 2009 (Uw = 1.3 W/(m2•K)) reduction of heat transfer is equal to about 0.2 W/(m2•K). As a result, significantly increases the level of thermal comfort in the evening and night. The potential energy saving depends on the climate and is shown in Fig. 7 for other types of Windows.

Energy efficiency in different climatic regions

For the exact calculation of the potential energy savings at the building level required information about climate data (duration of daylight, ambient temperature), the building structure and Windows (standard insulation, heat accumulating capacity), and heating technology (reducing heating at night). Local phenomena, such as heavy fog, high wind speed and the formation of cold air in the valley, are not taken into account. Given the important climatic effects (total radiation, wind data and temperature, as well as the position of the sun) and climate data according to metastandard [10] allows to accurately determine the rate of possible energy saving. According to EN ISO 13790 simulation of the factors affecting the building, based on a model of one room (DIN EN ISO 13791) and conducted by the Institute for window technology (Rosenheim) for different climatic regions.

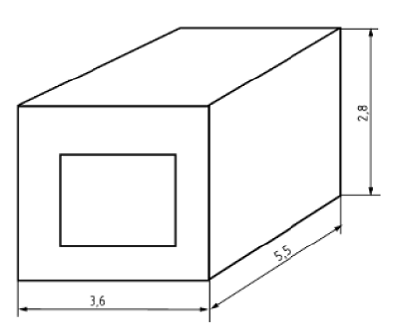

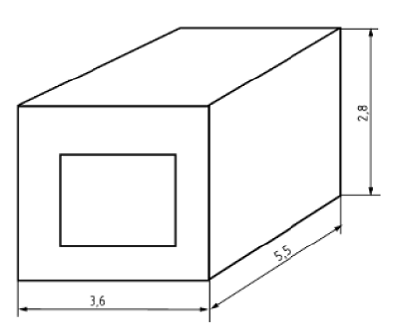

Fig. 5. Model one room to simulate the energy characteristics of Windows according to EN 13790

Potential energy correlates with the area of the window. This allows not to consider the factors relating to the building, such as heat loss in the air conditioner or the internal heat sources, as these factors equally apply to Windows, and sun protection. The influence of the smaller, the better the thermal insulation of buildings, Windows or glass.

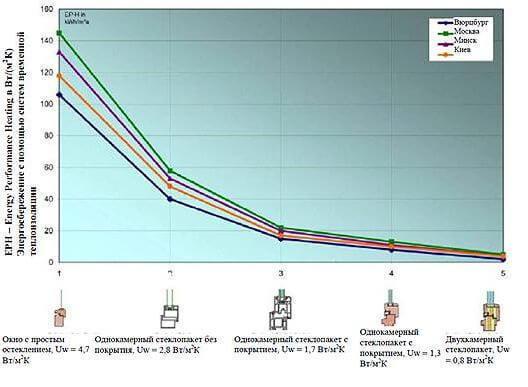

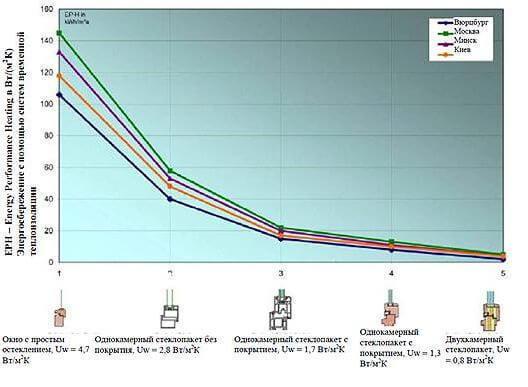

The example defines the energy efficiency for würzburg, Minsk, Moscow and Kiev. It is important to know which window is used, since the installation of solar shading to the lower the Uw heat transfer reduction will be less effective. For this reason, the study was simulated for a typical and most common types of Windows (table. 2).

Table 2. The window to assess the systems temporary thermal insulation. The size of the window of 1.23×1.48 m, the proportion of window frames – 30%

Window type

Uw (window), W/m2K

Ug (glazing) in W/m2K

Uf (frame), W/m2K

Ratio energopromis of birth g, %

1

Window with simple glass

4,7

5,9

2,0

0,85

2

Single-chamber glass without coating

2,8

3,0

2,0

0,77

3

Single-chamber glass with the coating

1,7

1,3

2,0

0,6

4

Single-chamber glass with the coating

1,3

1,1

1,4

0,6

5

Triple-pane Windows (energy efficient buildings)

0,80

0,7

0,96

0,5

Fig. 6. Energy saving for aluminium shutters with Rsh = 0,02 m2K/W and the 4th class of air tightness for different types of Windows in würzburg, Minsk, Moscow, Kiev, depending on the class of air tightness (Institute for window technology (Rosenheim) can also prepare the calculations for other designs and cities)

Conclusion

Shutters and other systems external solar shading effectively prevent overheating of premises in summer, thereby providing significant savings in energy consumption by air conditioning systems.

The use of suitable materials and appropriate construction systems can significantly reduce the rate of heat transfer Uw, especially old Windows and glazing. In addition to energy saving solar shading systems significantly improve thermal comfort indoors, as the temperature of the inner surface significantly increases. However, this depends on careful consideration of the design and results of the calculation of the rate of saving and testing for insulation recognized testing laboratories.

Given the important climatic effects (total radiation, wind data and temperature, as well as the position of the sun) and climate data according to metastandard [10] allows to accurately determine the rate of possible energy saving. Thus, the system of temporary insulation installed on the old window with a simple glazing, depending on the climatic conditions allows to save more than 140 kWh per 1 m2 of the window area per year (data for other types of Windows is shown in Fig. 8).

If the total window area of the building is 30 m2, the annual electricity savings will be around 4200 kWh, which corresponds to about 420 litres of liquid fuel. Setting sun on old Windows with single-chamber double-glazed Windows (2nd type) will save 60 kWh per 1 m2 of the window area per year, i.e., 1800 kWh per building. In addition, system temporary insulation increase security and protection from hacking. published

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: portal-energo.ru/articles/details/id/790

In addition to classical and well-known in the market for methods such as replacement Windows and providing better insulation of the external walls, intermediate floors and roofs, significantly improve the thermal insulation of the building helps the installation of shutters. First of all it concerns the countries with a continental climate characterized by cold winters and hot summers, and regions with low clouds.

Here shutters, sliding or hinged shutters will be doubly useful. As a means of temporary insulation on a cold winter night, they reduce the costs for heating and in summer as an effective sun screens reduce the need for air conditioning facilities. This article explains what design aspects of roller shutters it is necessary to consider how high the potential savings of electricity.

Physical and technical aspects

Under certain conditions, systems of internal and external sun protection, which are in accordance with EN 13659 shutters, sliding shutters, blinds and textile systems installed on transparent surfaces (Windows and glazed area), a cold night can be a means of thermal insulation. During the day they are applied seldom enough, as the residents of the houses prefer to use natural daylight and have visual contact with the outside world. To accurately calculate potential energy savings, it is necessary to take into account the various factors affecting a building. According to EN ISO 13790 imitation of such factors is based on the model of one room (DIN EN ISO 13791). This simplifies the process of identifying potential energy savings. In General, the effectiveness of the system of temporary insulation of the greatest influence have the following factors.

Airtightness of the system (static air layer and the thermal resistance according to EN 13125). The rate of thermal insulation systems (resistance to heat and radiation for infrared reflective coatings). The level of insulation of external walls and Windows/glazing. Climatic conditions (daylength and ambient temperature during the heating period). View of the control system and the time required to close the system (at certain hours or according to the length of a day). Indicator of the potential saving relates to an area of the window as all the factors equally affect both the Windows and system temporary insulation, and the improvement of the physical and technical characteristics of the restricted area of the transparent surface.

Fig.1. Important factors that affect the system temporary insulation

The heat transfer coefficient Uw

To accurately assess the potential energy efficiency of buildings should take into account climatic data, the design of the building, Windows and heating equipment. The buyer this information is usually unknown, and for fast evaluation, it is too time-consuming. For this reason, it is also important to consider the decrease in heat transfer coefficient ΔUw – parameter, well known to architects, manufacturers and builders. However, to directly determine the rate of potential energy saving in this case is impossible, since the heat transfer coefficient decreases only when use of a temporary insulation. To determine the temperature of the inner surface of the indicator ΔUw,tws (decrease of heat transfer coefficient of the window system temporary insulation), of course, of great importance. Below are calculations for systems external solar shading installed on the standard size according to EN 14351-1: of 1.23×1.48 m, the proportion of the window frames 30%.

Uw – heat transfer coefficient of Windows, W/(m2•K)

Uf – thermal transmittance of the window frame, W/(m2•K)

Ug – thermal transmittance coefficient of the glazing, W/(m2•K)

Af – area of the window frame, m2

Aw is the window area, m2 (AF + Ad)

Ag – area of glazing, m2

lg – the length of the perimeter connections of the glazing to the profile, m

Ψg is the linear heat transfer coefficient, W/(m•K)

ΔR is the resistance to heat transfer of the external sun protection, (m2•K)/W

ΔUw,tws is the reduction of heat transfer coefficient of Windows with sun screens, W/(m2•K).

Reducing heat transfer through the system temporary insulation depends on the thermal resistance of the external sun protection ΔR, which is significantly affected by the permeability of the system and the rate of thermal insulation. The total value of clearances etot (side, top and bottom) is calculated according to the following formula:

Depending on the indicator etot of the system of external solar shading are divided into five classes according to EN 13125 (table. 2). The highest level of air tightness (class 5) is achieved in the case when rolling the canvas, no air and light gaps (slats abut each other or located lapped), and the total value of clearances between the system and external solar shading external wall, window or façade is less than 3 mm. air Permeability according to EN 13125 presented in table 1, the exact figures are measured based on the provisions of EN 12835. Standard EN 13125 establishes the minimum airtightness classes for specific designs. For example, folding shutters (accordion) meet 1st class, RAF-curtains with the United or fixed lamellas in the closed position — 2nd class.

Table 1. Classes of air permeability according to EN 13125

Class

Feature

etot

ΔR in (m2·K)/W

1

The high breathability

>35 mm

ΔR = 0,08

2

High breathability

15-35 mm

ΔR = 0,25 xRsh + 0,09

3

Average breathability

8-15 mm

ΔR = 0,55 xRsh + 0,11

4

Low permeability

3-8 mm

ΔR = xRsh 0,80 + 0,14

5

Airtight system

<3 mm

ΔR = 0,95 xRsh + 0,17

The heat resistance coefficient rolling canvas Rsh or other exterior sun protection shall be specified by the supplier. It is determined by tests using thermal chambers according to EN ISO 12567-1 or calculated according to EN ISO 10077-2 and must be specified with a precision to hundredths. Both studies are conducted in the Institute of window technology (Rosenheim). Applied to the system of internal solar infrared reflective coating is taken into account through the index k, which depends on the emissivity ε of the coating and multiplied by ΔR.

Fig. 2. The decrease in heat transfer coefficient ΔUw in W/(m2•K) for Windows with Uw = 2.8 W/(m2•K) temporary insulation, depending on the heat resistance of rolling cloth and Rsh class of air tightness according to EN 13125

System design

The system design of the temporary heat protection (shutters, blinds, etc.) should not only increase the insulation, but also to perform several other important functions: to protect from the sun, hacking, heavy rain, hail and wind. On the rate of thermal insulation protection systems influence thermal resistance of the material (rolling blade) and airtightness. To the greatest extent the tightness of the joint system of external sun protection and temporary insulation on exterior wall, window or façade: between the time system of insulation and window needs to form a static air layer.

Fig. 3. The distribution of gaps according to EN 13125 (photo ALUTECH group of companies, the test Report of the ift No. 11-000216-PR03)

Reduce the heat loss when applying an infrared reflective coating for internal sun protection is subject to the following conditions.

Layer infrared-reflecting coating applied to the weak convection, as a rule, on the side facing the window. Best on buildings with low insulation". Protect coating from contamination". The coating is protected from damage during cleaning or operation. In the system of external solar shading of the infrared reflective coating may not be taken into account according to EN 13125, as well as due to contamination during operation.

Example of calculation

The definition of a possible decrease in heat transfer coefficient Uw is shown in the example window shutters made of aluminium. This design also provides more reliable protection against burglary. Used to calculate roll system RS.AR41 ALUTECH group of companies (see test report of the ift No. 11-000216-PR03).

Fig. 4. The joints and gaps, providing 4th class of air tightness according to EN 13125 (drawings ALUTECH group of companies from the test report of the ift No. 11-000216-PR03)

Product description and parameters

Roll system consisting of a rolling cloth with end profile, roller shutter boxes, side rail and bottom of the tire as a frame. Aluminium profile filled with polyurethane foam. Bus and terminal profiles made of aluminum have a sealing insert made of EPDM. Design of roller shutter boxes seals does not provide.

The size of the gap between the rolling blade and boxes or building blocks:

the clearance from bottom 0 mm

the clearance from the top – 5 mm

the clearance on the sides (left and right) – 1 mm

Rsh = 0,02 in (m2•K)/W

The calculation of the additional resistance to heat transfer

The distribution on classes of air permeability according to EN 13125:

the clearance from below: e1 = 0 mm

the clearance from the top: e2 = 5 mm

the clearance from the side: e3 = 1 mm

the total value of clearances: etot = e1 + e2 + e3 = 6 mm

Air and light gaps in rolling the canvas out of the slats abut each other. In accordance with the requirements to the 4th class of air permeability according to EN 13125 total value of clearances etot must be ≤ 8 mm. In this case, the above construction corresponds to the 4th class according to EN 13125.

Additional thermal resistance ΔR when Rsh = 0,02 in (m2•K)/W is calculated when tested by the method of thermal imaging cameras as follows (see table. 1):

ΔR = 0,8 × Rsh + 0,14 = 0,8 × 0,02 in (m2•K)/W + 0,14 = 0,16 (m2•K)/W

When installing temporary insulation in the old window (Uw = 2.8 W/(m2•K)) reduction of heat transfer is about 0.85 W/(m2•K), and when you install such a system on a modern window according to the decree on energy efficiency of 2009 (Uw = 1.3 W/(m2•K)) reduction of heat transfer is equal to about 0.2 W/(m2•K). As a result, significantly increases the level of thermal comfort in the evening and night. The potential energy saving depends on the climate and is shown in Fig. 7 for other types of Windows.

Energy efficiency in different climatic regions

For the exact calculation of the potential energy savings at the building level required information about climate data (duration of daylight, ambient temperature), the building structure and Windows (standard insulation, heat accumulating capacity), and heating technology (reducing heating at night). Local phenomena, such as heavy fog, high wind speed and the formation of cold air in the valley, are not taken into account. Given the important climatic effects (total radiation, wind data and temperature, as well as the position of the sun) and climate data according to metastandard [10] allows to accurately determine the rate of possible energy saving. According to EN ISO 13790 simulation of the factors affecting the building, based on a model of one room (DIN EN ISO 13791) and conducted by the Institute for window technology (Rosenheim) for different climatic regions.

Fig. 5. Model one room to simulate the energy characteristics of Windows according to EN 13790

Potential energy correlates with the area of the window. This allows not to consider the factors relating to the building, such as heat loss in the air conditioner or the internal heat sources, as these factors equally apply to Windows, and sun protection. The influence of the smaller, the better the thermal insulation of buildings, Windows or glass.

The example defines the energy efficiency for würzburg, Minsk, Moscow and Kiev. It is important to know which window is used, since the installation of solar shading to the lower the Uw heat transfer reduction will be less effective. For this reason, the study was simulated for a typical and most common types of Windows (table. 2).

Table 2. The window to assess the systems temporary thermal insulation. The size of the window of 1.23×1.48 m, the proportion of window frames – 30%

Window type

Uw (window), W/m2K

Ug (glazing) in W/m2K

Uf (frame), W/m2K

Ratio energopromis of birth g, %

1

Window with simple glass

4,7

5,9

2,0

0,85

2

Single-chamber glass without coating

2,8

3,0

2,0

0,77

3

Single-chamber glass with the coating

1,7

1,3

2,0

0,6

4

Single-chamber glass with the coating

1,3

1,1

1,4

0,6

5

Triple-pane Windows (energy efficient buildings)

0,80

0,7

0,96

0,5

Fig. 6. Energy saving for aluminium shutters with Rsh = 0,02 m2K/W and the 4th class of air tightness for different types of Windows in würzburg, Minsk, Moscow, Kiev, depending on the class of air tightness (Institute for window technology (Rosenheim) can also prepare the calculations for other designs and cities)

Conclusion

Shutters and other systems external solar shading effectively prevent overheating of premises in summer, thereby providing significant savings in energy consumption by air conditioning systems.

The use of suitable materials and appropriate construction systems can significantly reduce the rate of heat transfer Uw, especially old Windows and glazing. In addition to energy saving solar shading systems significantly improve thermal comfort indoors, as the temperature of the inner surface significantly increases. However, this depends on careful consideration of the design and results of the calculation of the rate of saving and testing for insulation recognized testing laboratories.

Given the important climatic effects (total radiation, wind data and temperature, as well as the position of the sun) and climate data according to metastandard [10] allows to accurately determine the rate of possible energy saving. Thus, the system of temporary insulation installed on the old window with a simple glazing, depending on the climatic conditions allows to save more than 140 kWh per 1 m2 of the window area per year (data for other types of Windows is shown in Fig. 8).

If the total window area of the building is 30 m2, the annual electricity savings will be around 4200 kWh, which corresponds to about 420 litres of liquid fuel. Setting sun on old Windows with single-chamber double-glazed Windows (2nd type) will save 60 kWh per 1 m2 of the window area per year, i.e., 1800 kWh per building. In addition, system temporary insulation increase security and protection from hacking. published

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: portal-energo.ru/articles/details/id/790